Metal sheet cupping test method related to strain rate

A technology of cupping test and deformation speed, which is applied in the direction of metal processing equipment, analysis materials, strength characteristics, etc., can solve the problems of large error, insufficient sensitivity or intuition of timing, etc., and achieve the effect of improving product qualification rate and forming process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

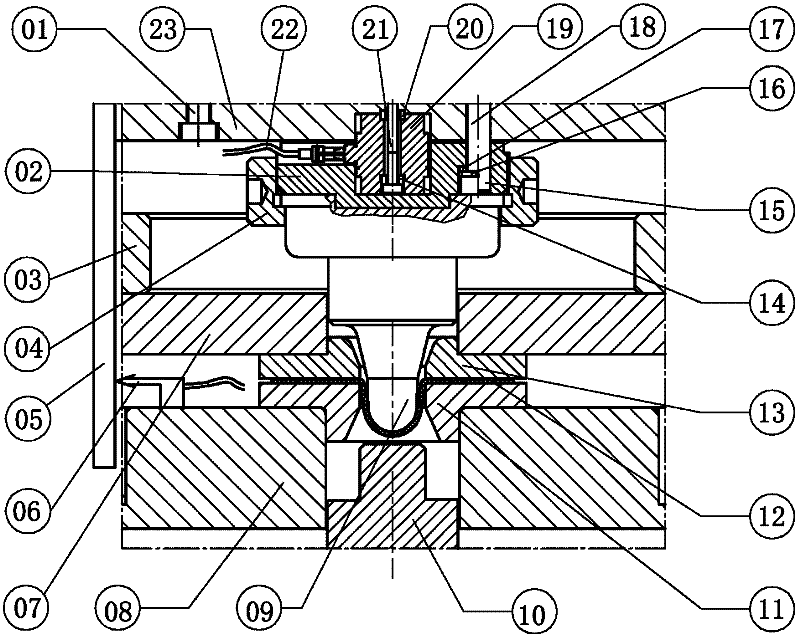

Method used

Image

Examples

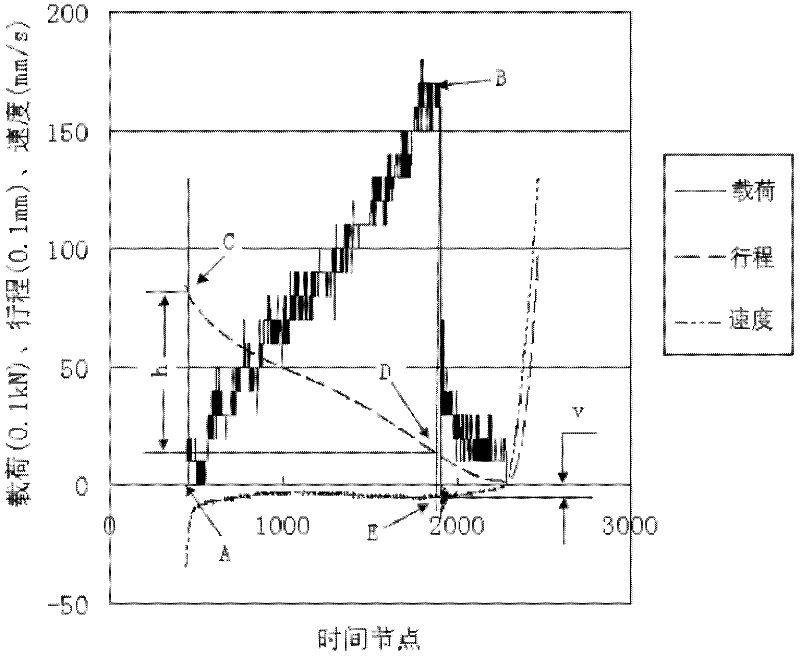

example 1

[0026] Example 1: Adjust the closing height of the servo press to 300mm; set the slider speed of the servo press to two stages, the first stage is 100% (the target position is 10mm from the bottom dead center), and the second stage is 10%; the sample A brass plate with a diameter of 1.0mm and a diameter of 98.2mm; the experimental environment temperature is 20°C, the surface of the sample is coated with a little engine oil, four samples are made repeatedly, the test data is recorded, and the average value is calculated to obtain "speed 10%, yellow Copper plate, time-load-travel-speed relationship curve" such as figure 2 shown in figure 2 Draw a straight line parallel to the ordinate through the initial load mutation point A and the penetration load mutation point B, intercept the load line to obtain points C and D, measure and calculate the difference between the vertical coordinates of C and D h=7.14mm , is the change of the actual position of the punch from the moment whe...

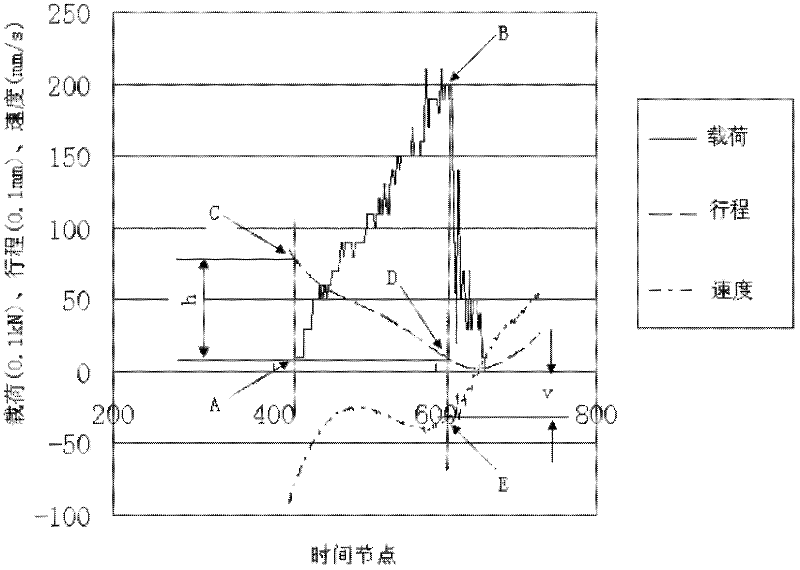

example 2

[0027] Example 2: Adjust the closing height of the servo press to 300mm; set the slider speed of the servo press to two stages, the first stage is 100% (the target position is 10mm from the bottom dead center), and the second stage is 80%; the sample A brass plate with a diameter of 1.0mm and a diameter of 98.2mm; the experimental environment temperature is 20°C, the surface of the sample is coated with a little engine oil, four samples are made repeatedly, the test data is recorded, and the average value is obtained to obtain "speed 80%, brass Plate, time-load-travel-speed relationship curve" such as image 3 As shown; similarly measure and calculate the difference h=6.94mm between C and D ordinates, and measure the ordinate value of point E as v=35mm / s. IE(v) = 6.94(35)mm was recorded for this sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com