Flange ball valve body forging technology

A flange type, ball valve technology, applied in the direction of the valve device, etc., to achieve the effect of good product quality control, uniform internal metallographic structure, and good forging streamlines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Technical solution of the present invention is:

[0027] 1. Selection of billet

[0028] For better forging and forming, the forming process is determined as follows: according to the change of different cross-sections of this product, a round bar with a diameter of 80 is selected as the raw material;

[0029] 2. Intermediate frequency induction furnace GRT120 intermediate frequency heating, heating time 45s material heating temperature 1150±50°;

[0030] 3. Use C41-75 to make the blank, the purpose is to remove the scale and preform;

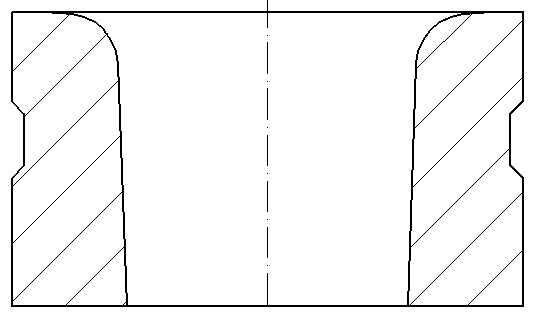

[0031] 4. use figure 1 The blank-making mold shown is used for blank-making;

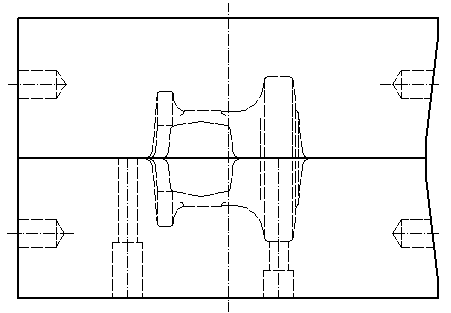

[0032] 5. use figure 2 The pre-forging die shown is used for pre-forming;

[0033] 6. Use image 3 The pre-forging die shown is for terminal forming, and the terminal forming temperature is ≥1000°C;

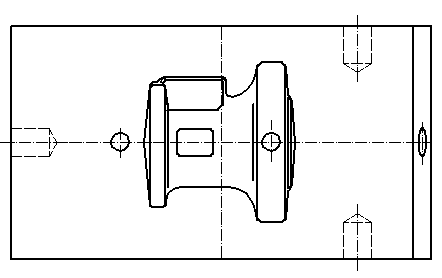

[0034] 7. use Figure 4 The final forging die shown is trimmed, and the trimming temperature is ≥950°C;

[0035] 8. Use an angle grinder to remove resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com