Automatic drilling and tapping machine tool for valves

A technology of automatic tapping and drilling mechanism, used in metal processing machinery parts, large fixed members, feeding devices, etc., can solve the problems of reduced production efficiency and product qualification rate, increased machine and labor costs, time-consuming and labor-intensive, etc. The effect of saving machine and labor costs, improving production efficiency and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

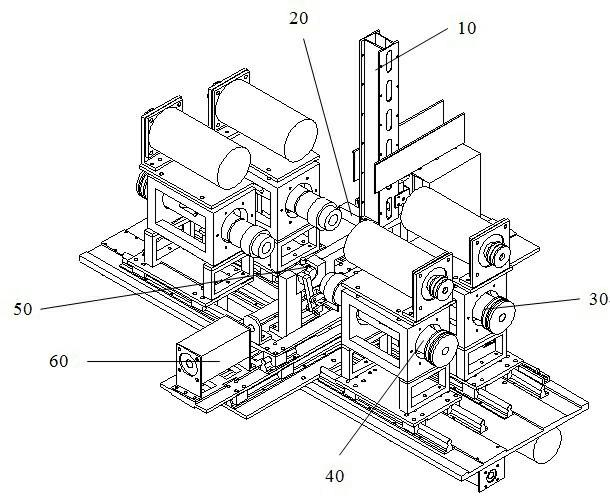

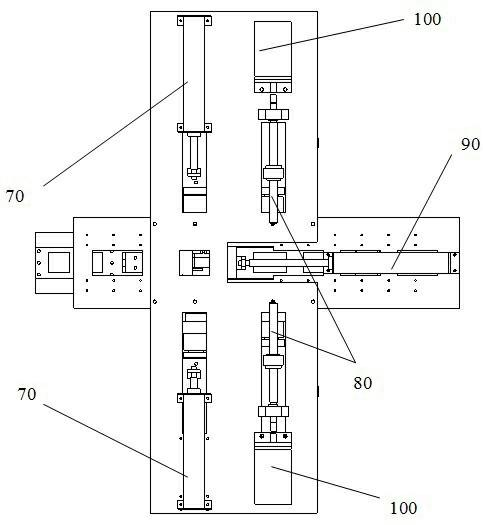

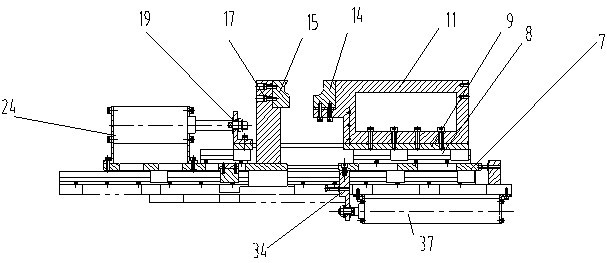

[0022] The invention provides a valve automatic drilling and tapping machine tool. The valve automatic drilling and tapping machine tool includes blanking mechanism, workpiece positioning mechanism, automatic drilling mechanism, automatic tapping mechanism, workpiece clamping mechanism, main clamping cylinder, tapping mechanism feed cylinder, and drilling mechanism transmission The screw rod, the table feed cylinder, the drilling mechanism feed servo motor, the blanking mechanism is vertically arranged on the base of the machine tool, the workpiece clamping mechanism is arranged at the bottom of the blanking mechanism, and the workpiece clamping mechanism Connecting the main clamping cylinder and the table feed cylinder, the automatic drilling mechanism includes a pair of coaxial and opposite automatic drilling power heads, the automatic tapping mechanism is parallel to the automatic drilling mechanism, and includes a For coaxial and opposite automatic tapping power heads, each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com