Automatic deformation screening machine for pins of connector housings

An automatic screening and connector technology, applied in sorting and other directions, can solve the problems of high labor costs, difficult to quantify, and high work intensity, so as to improve production efficiency and product qualification rate, improve detection efficiency and accuracy, shorten the The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

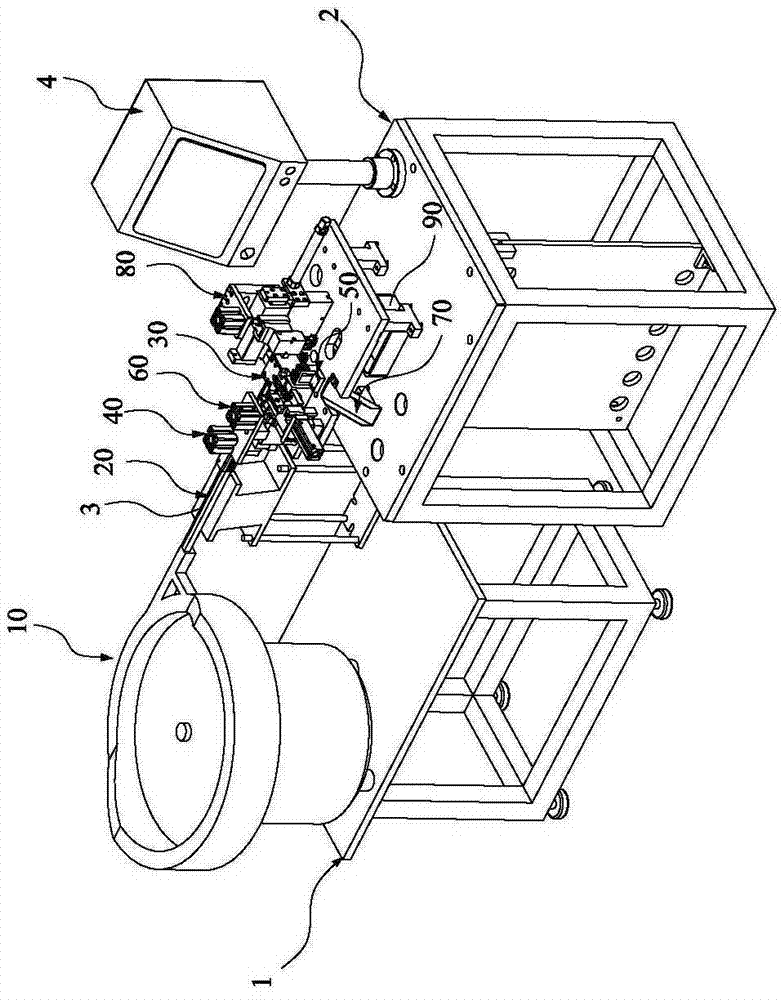

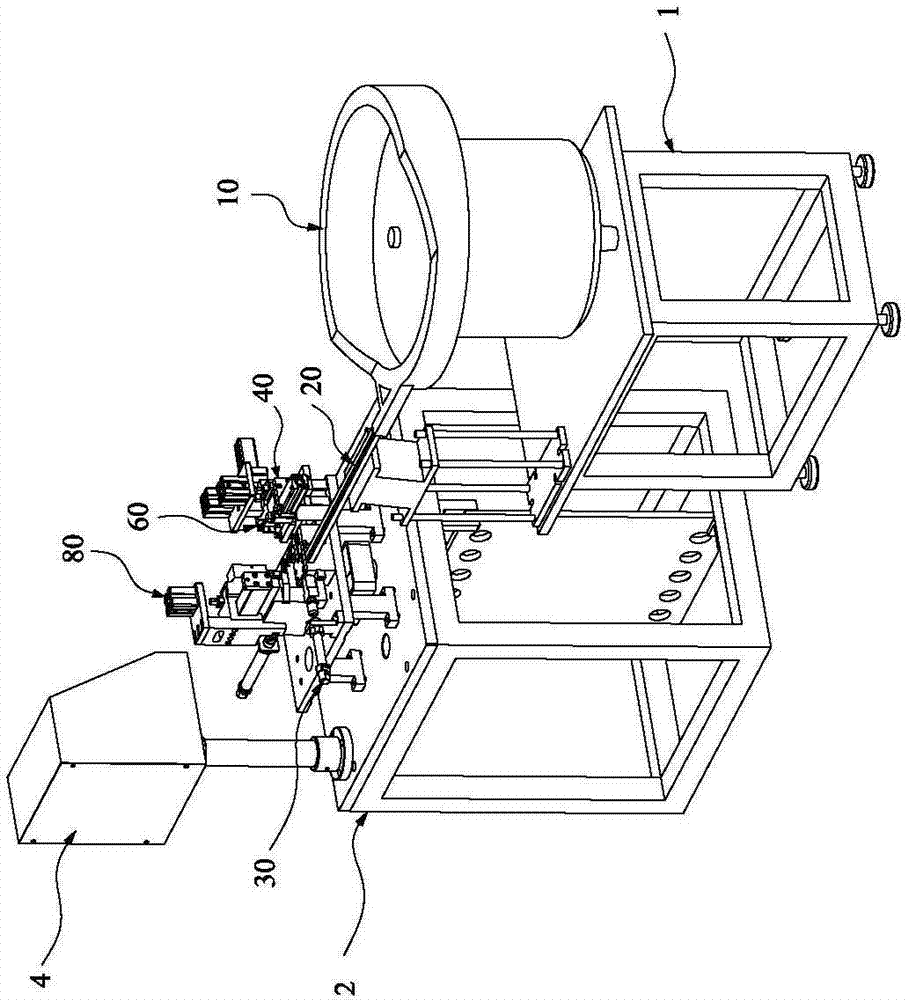

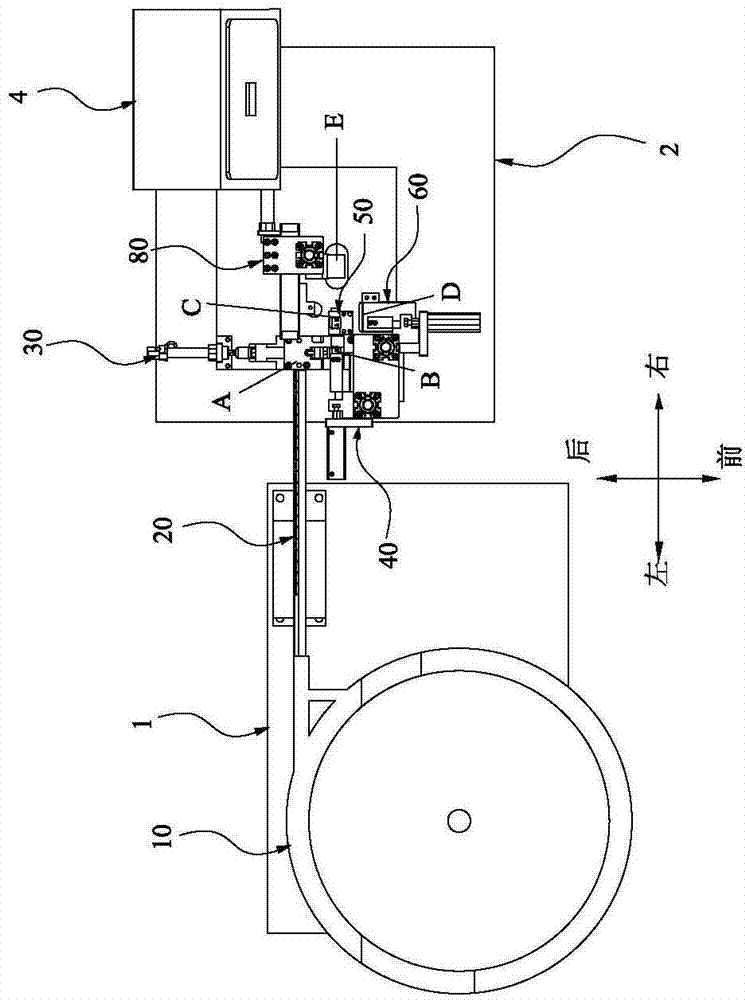

[0083] Please refer to Figure 1 to Figure 4 As shown, it has shown the concrete structure of the preferred embodiment of the present invention, and this connector housing pin deformation automatic screening machine includes vibrating plate mounting frame 1, the vibrating plate 10 that is installed on the vibrating plate mounting frame 1, vibrating plate The feeding channel 20, the screening machine also includes a testing platform 2, a pushing mechanism 30 installed on the testing platform 2, a feeding manipulator 40, a testing mechanism 50, a first sending manipulator (that is, a good product sending manipulator) 60, and a good product sending channel 70. The second sending manipulator (that is, the manipulator for sending out defective products) 80. The collecting box 90 for defective products. The vibrating feeding channel 20 is built between the vibrating plate 10 and the detection platform 2, and the detection platform 2 has a feeding station A, a suction loading station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com