Gantry type double-head computer numerical control (CNC) milling machine for hub machining

A CNC milling machine and gantry technology, applied in milling machines, milling machine equipment, metal processing and other directions, can solve the problems of increased tool holder weight, low production efficiency, and inability to adapt to mass production of forged wheels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

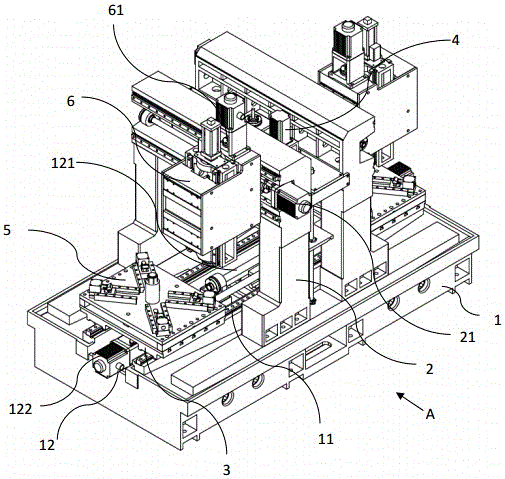

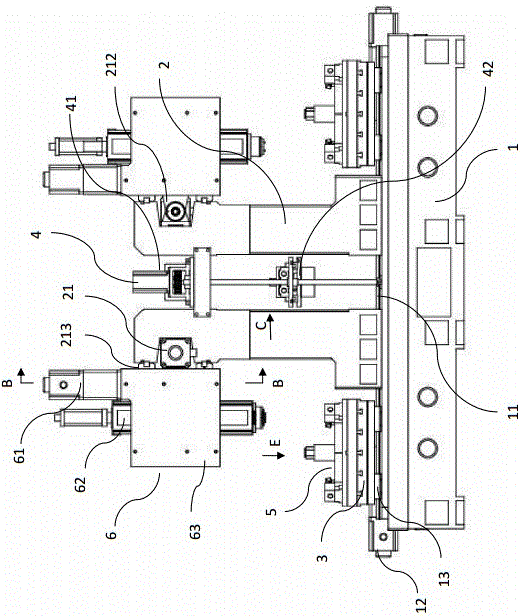

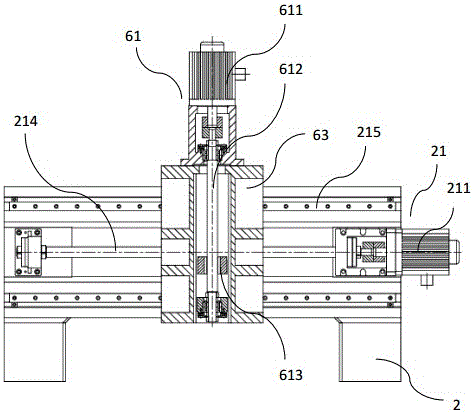

[0024] like figure 1 , figure 2 As shown, the gantry-type double-head CNC milling machine for wheel hub processing includes a base 1, and the base 1 is provided with two symmetrical gantry frames 2, and at the opposite positions of the two gantry frames 2 Both end milling head devices 6 are installed, and an end milling head 62 is installed in the end milling head device 6 . The end milling head 62 on the left side is used for roughing, and the end milling head 62 on the right side is used for finishing, so this device can carry out roughing and finishing operation to workpiece.

[0025] The machine base 1 is provided with a longitudinal guide rail 11, and the longitudinal guide rail 11 runs through two gantry frames 2. Two workbenches 3 are movably installed on the longitudinal guide rail 11, and the workbench 3 on the left side is located on the left side. Below the end milling head 62 , the workbench 3 on the right is located below the end milling head 62 on the right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com