Full-electrode-lug cell automatic assembly line

An automatic assembly and assembly line technology, applied in the direction of non-electric welding equipment, battery assembly machine, secondary battery manufacturing, etc., can solve the problems of low production efficiency and automation, cumbersome battery assembly production process, and affecting the health of operators, etc. Achieve the effects of easy implementation, high degree of automation, work efficiency and product qualification rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples are further explanations and supplements to the present invention, and will not constitute any limitation to the present invention.

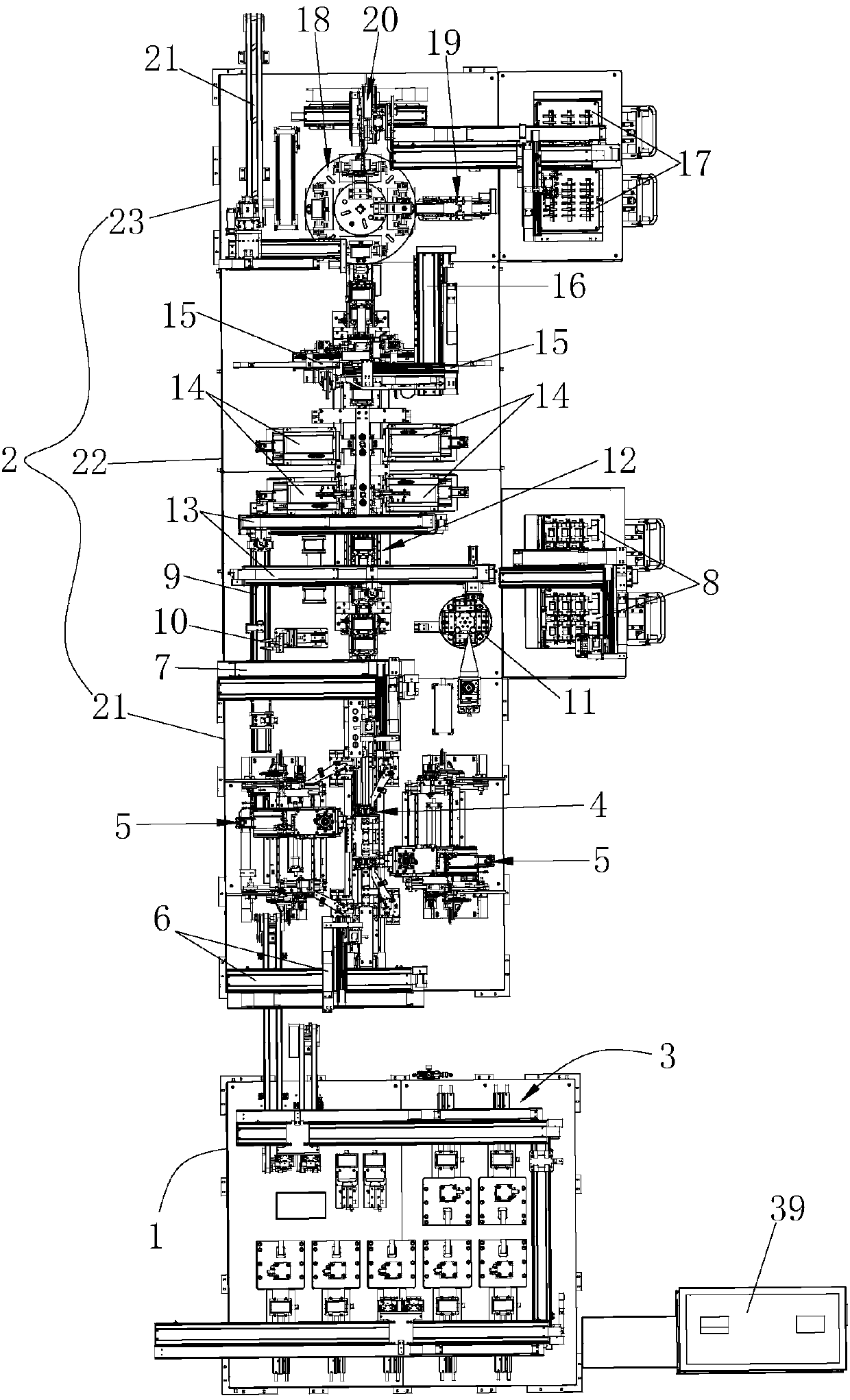

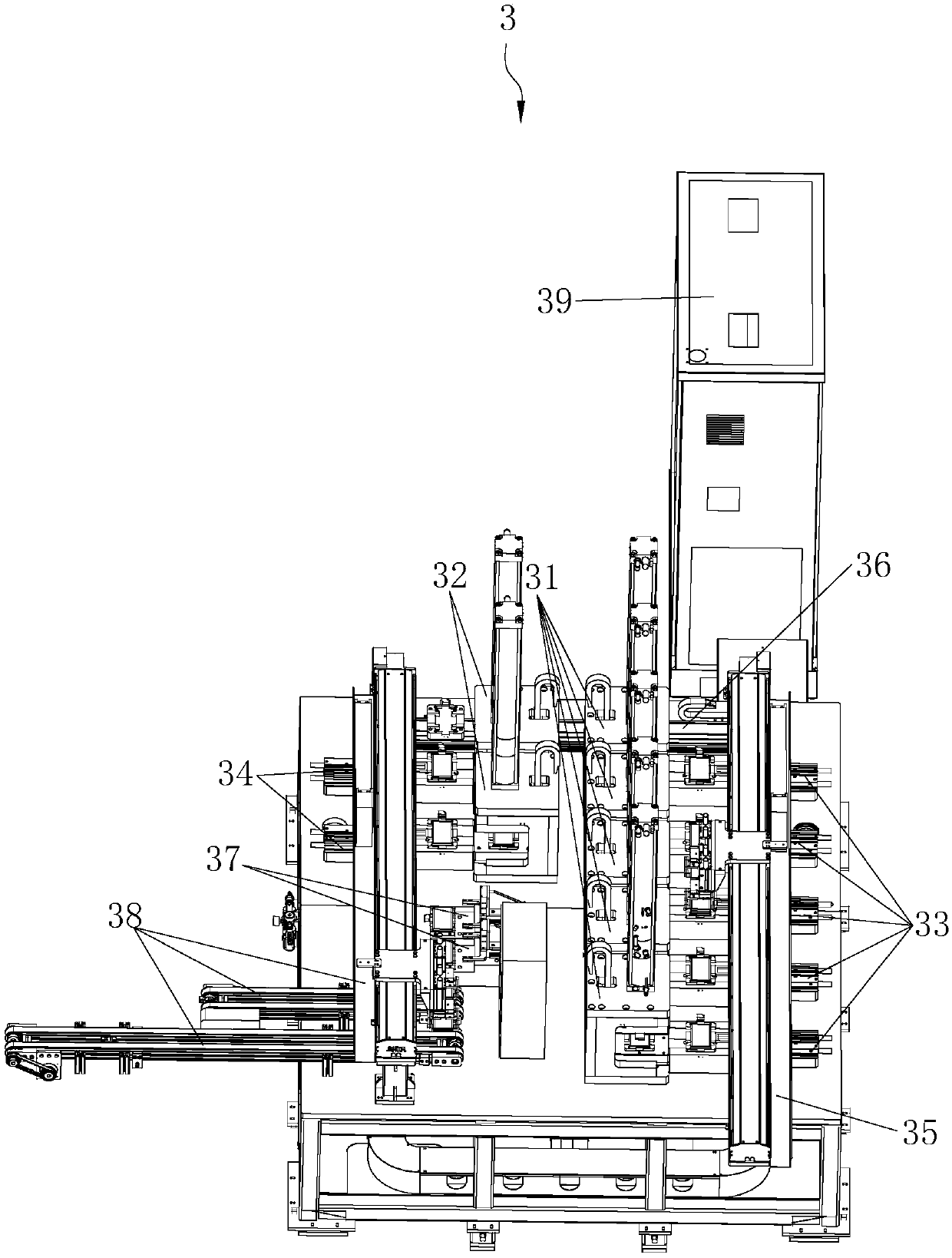

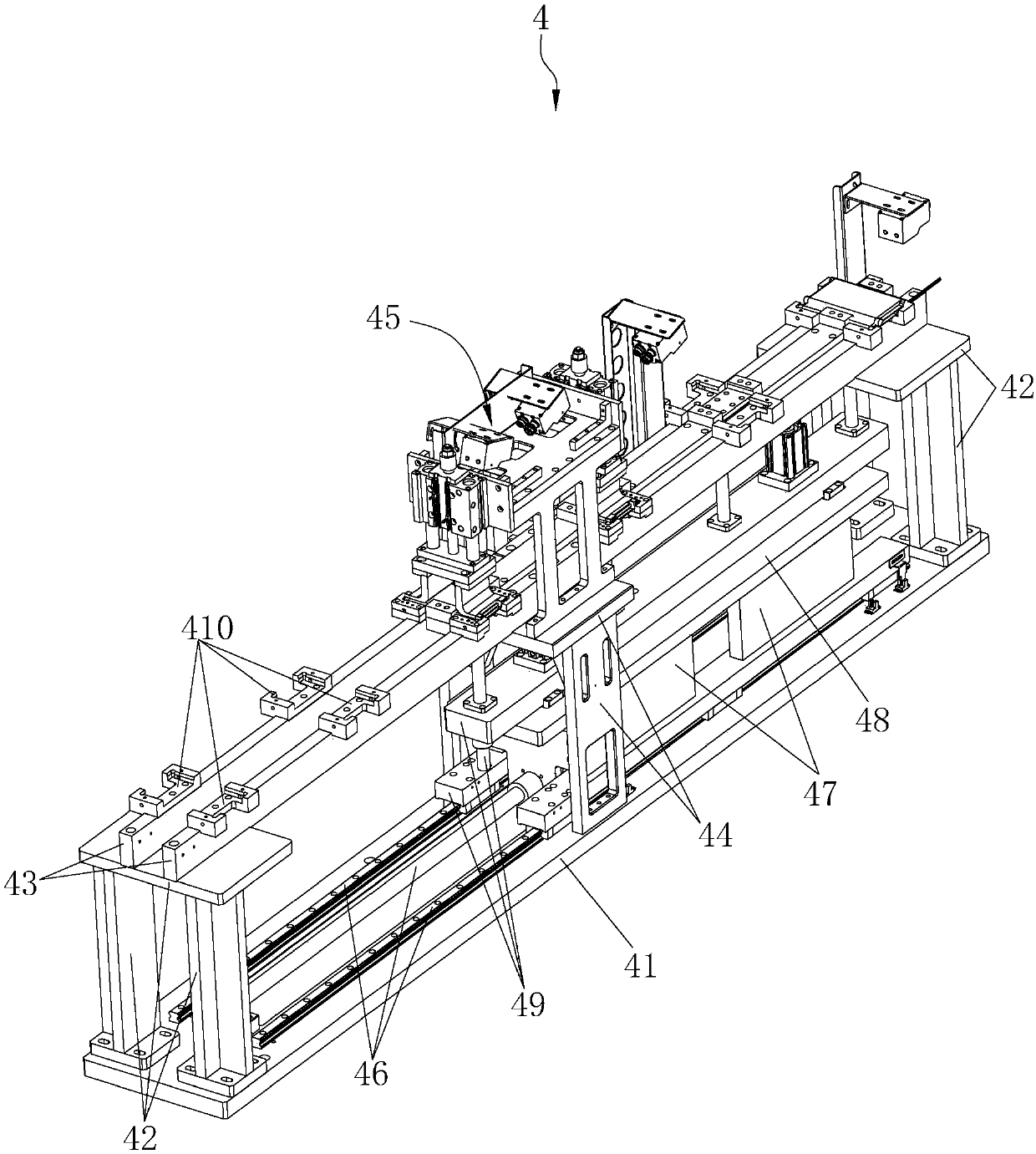

[0027] Such as Figure 1 to Figure 8 As shown, the automatic assembly line for all tab cells of the present invention includes: a first rack group 1, a second rack group 2, a hot and cold pressing mechanism 3, a first cell clamp transfer mechanism 4, a pre-welding mechanism 5, Cell incoming component 6, lower cell component 7 in the front section, cover plate feeding component 8, cell storage component 9, cell flipping component 10, marking component 11, second cell clamp transmission mechanism 12, material grabbing Module 13, welding mechanism 14, first glue-applying component 15, middle lower cell component 16, feeding component 17, turntable mechanism 18, spacer mechanism 19, second glue-applying component 20 and rear lower cell component twenty one.

[0028] Such as figure 1 , figure 2 As shown, in this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com