Automatic multi-station boring machine

A multi-station, drilling machine technology, used in boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problem of high labor intensity, low processing efficiency, and unguaranteed processing accuracy. and other problems to achieve the effect of reducing labor intensity and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

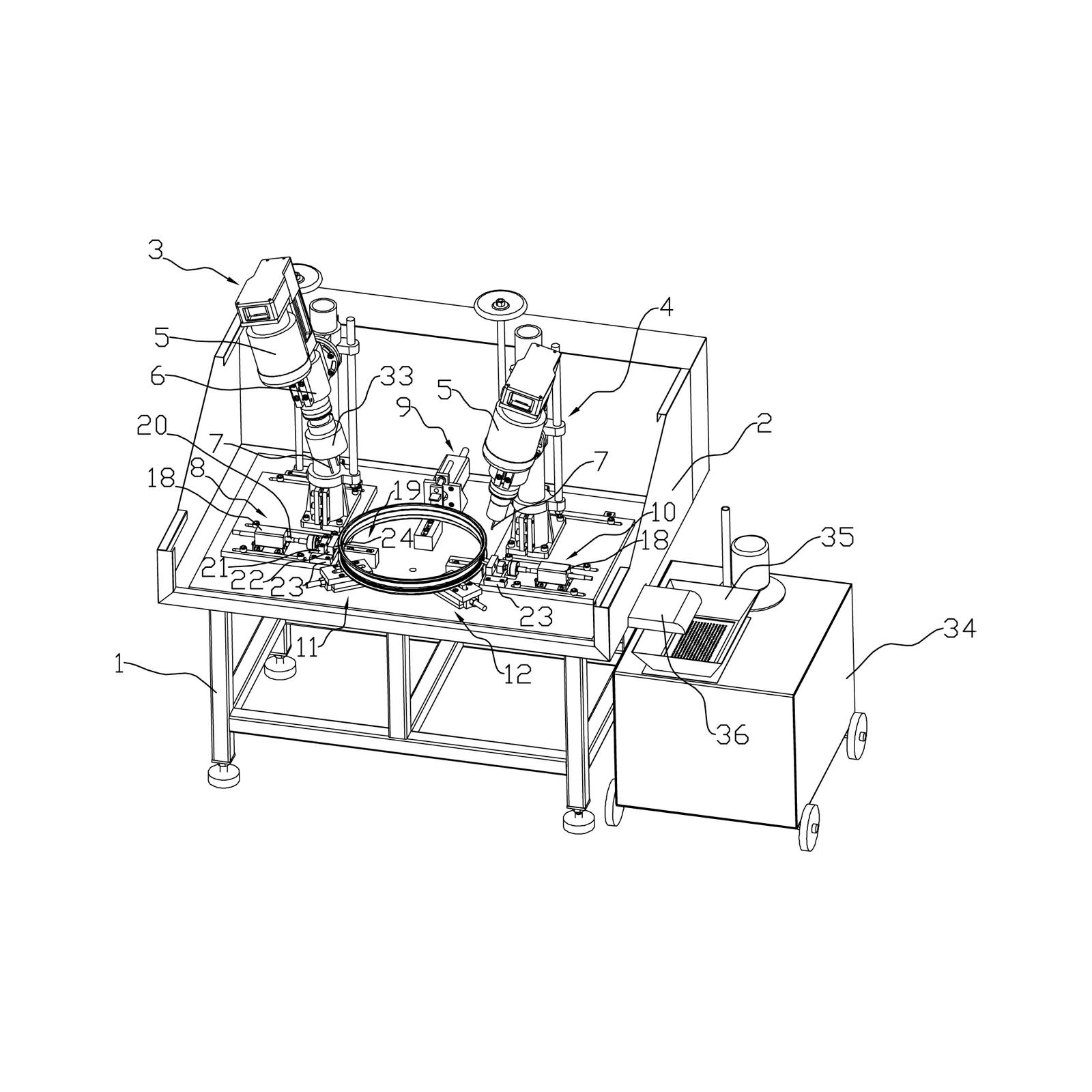

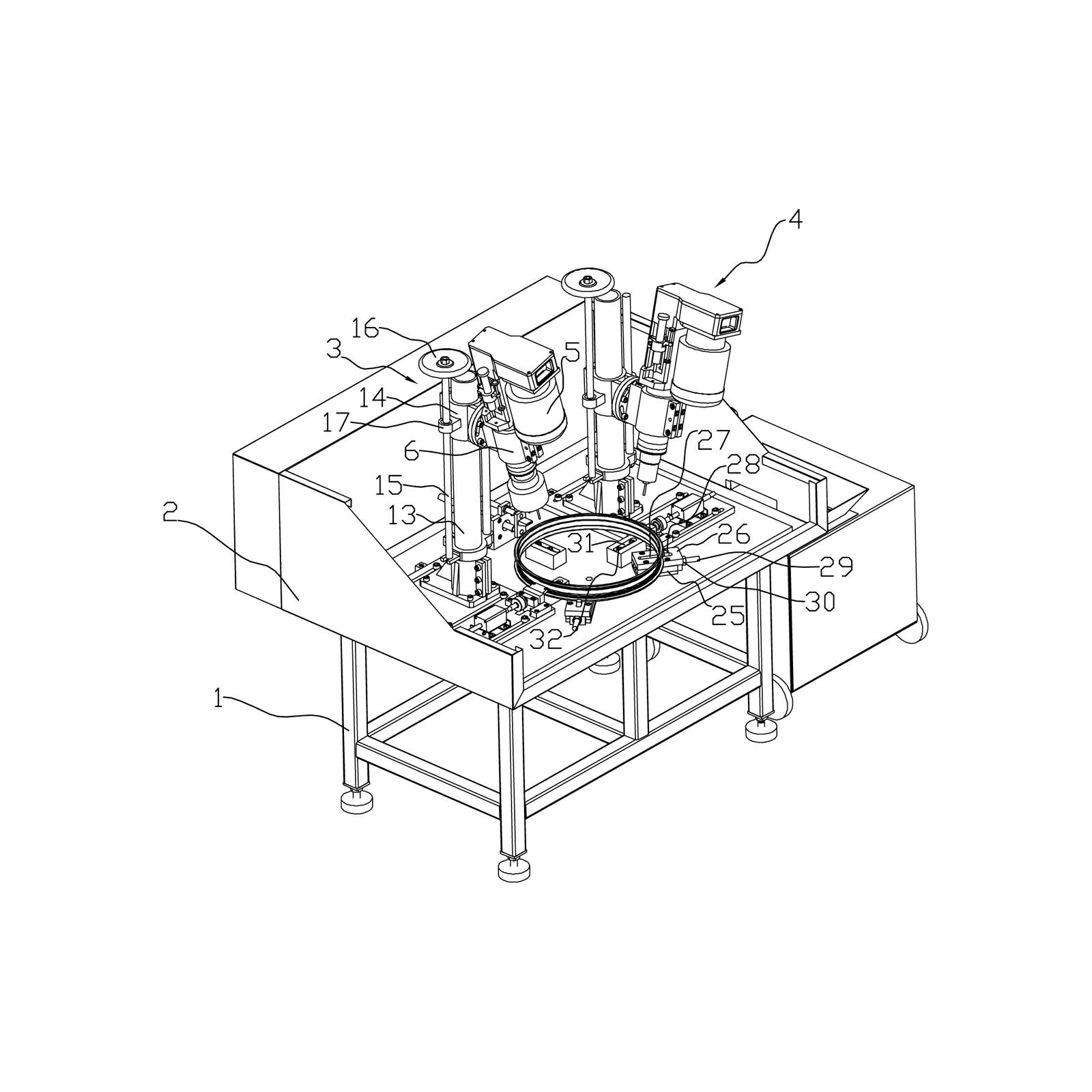

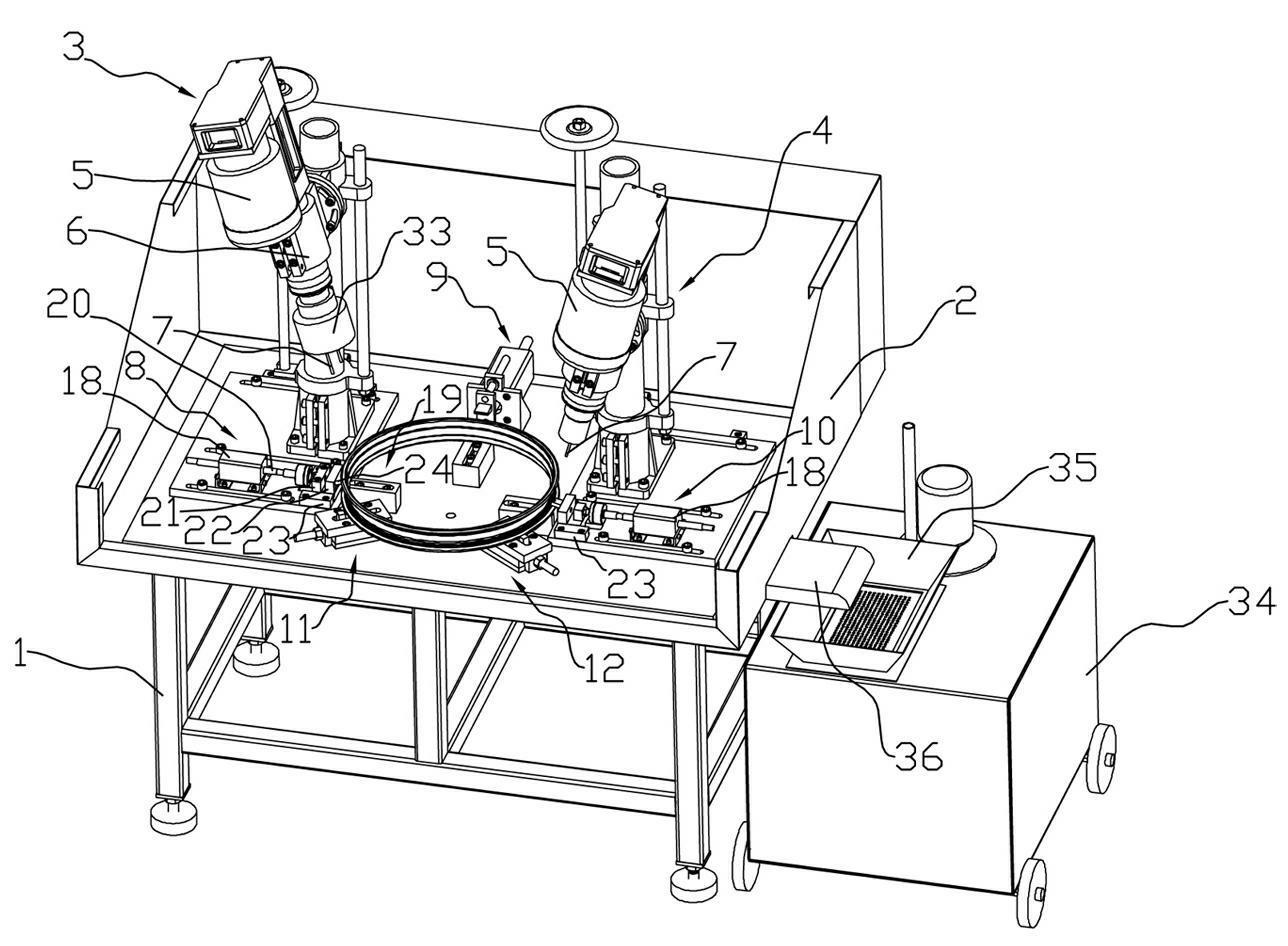

[0014] refer to figure 1 , figure 2 , the automatic multi-station drilling machine of the present invention comprises a frame 1, a workbench 2 is installed on the frame 1, and first and second drilling mechanisms 3, 4 are installed on the workbench 2, and the first 1. A motor 5 is installed on the second drilling mechanism 3 and 4, and the motor 5 drives the drill bit 7 located at the lower part of the drilling mechanism through the transmission part 6. The workbench 2 is provided with left, middle and right clamping mechanisms 8 and 9 , 10 and the first and second positioning mechanisms 11 and 12 opposite to the middle clamping mechanism 9, wherein the left and right clamping mechanisms 8 and 10 are opposite in direction. The first drilling mechanism 3 is provided with a biaxial assembly 33 driven by the motor 5, and two drill bits are installed on the working end of the biaxial assembly 33. When processing, place the wheel hub to be processed in the left, middle and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com