Processing method for rapidly tempering low-e glass

A low-e, processing method technology, applied in glass tempering, glass production, glass manufacturing equipment, etc., can solve problems such as easy glass oxidation, reduced equipment service life, and easy local occurrence, so as to improve quality and product qualification rate, improve production efficiency, and solve the effect of slow heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

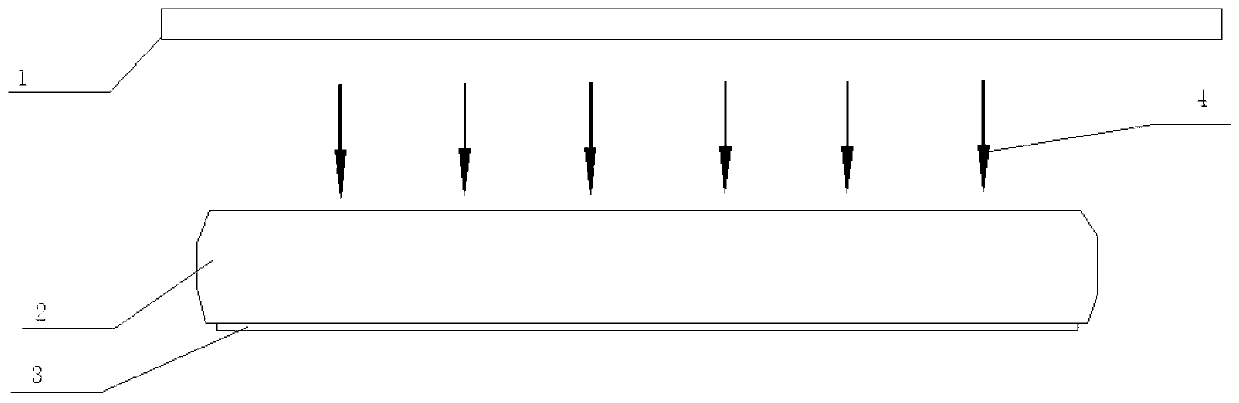

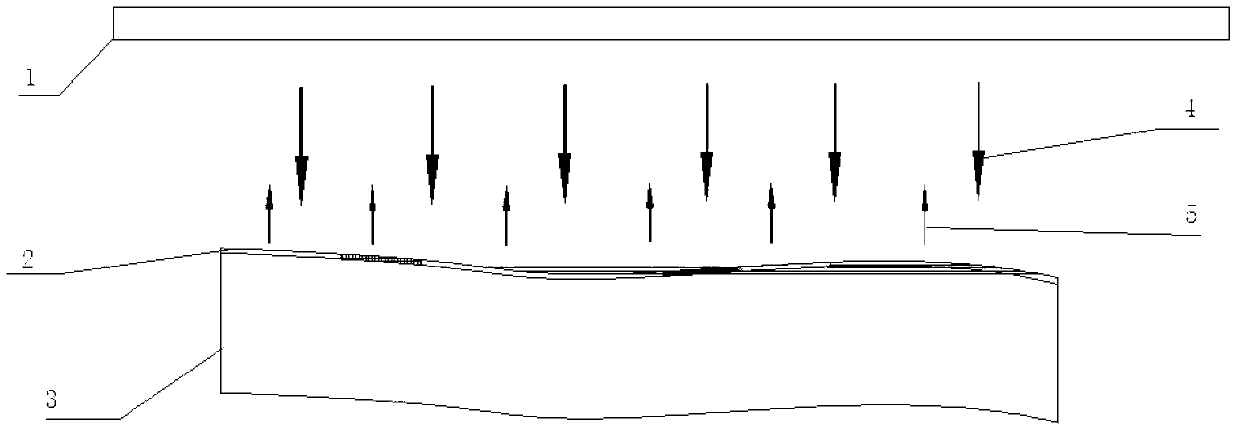

[0023] Embodiments of the present invention are described in detail below according to the accompanying drawings:

[0024] Such as figure 1 Shown: a kind of processing method of fast toughened low-e glass, comprises the steps:

[0025] (1) Cut the glass 2 into a specified size according to requirements;

[0026] (2) performing edge grinding on the glass 2;

[0027] (3) put the low-e film 3 of the glass 2 facing down, and put it into the heating furnace of the tempering furnace;

[0028] (4) First, preheat the upper and lower surfaces of the glass: the preheating temperature of the upper surface of the glass is 380-520 degrees Celsius, the preheating temperature of the lower surface of the glass is 370-510 degrees Celsius, the upper surface of the glass The speed efficiency of the surface preheating convection fan is 80%-90%, and the speed efficiency of the glass lower surface preheating convection fan is 70%-80%; the preheating time is 150-250 seconds, and then the glass is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com