Formaldehyde-free wood adhesive film

A wood glue and mucous membrane technology, applied in the direction of adhesives, natural rubber adhesives, halogen rubber derivative adhesives, etc., can solve the problem of inability to achieve zero formaldehyde free and release, difficult to large-scale production, inconvenient transportation and storage, etc. problems, to achieve the effect of eliminating pollution sources, cost-effective, and improving the construction environment

Inactive Publication Date: 2014-08-06

杨学荣

View PDF1 Cites 45 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, because the former cannot achieve zero formaldehyde dissociation and release, the latter is difficult to promote due to various factors, and it is not easy to form large-scale production

Furthermore, because most of the "trialdehyde glue" and other glue types are solvent-based and emulsion-based, there are disadvantages such as inconvenient transportation and storage, restricted by curing conditions, and short shelf life.

In addition, due to the poor water resistance of urea-formaldehyde glue, especially boiling water resistance, it is also a subject that the industry must overcome

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

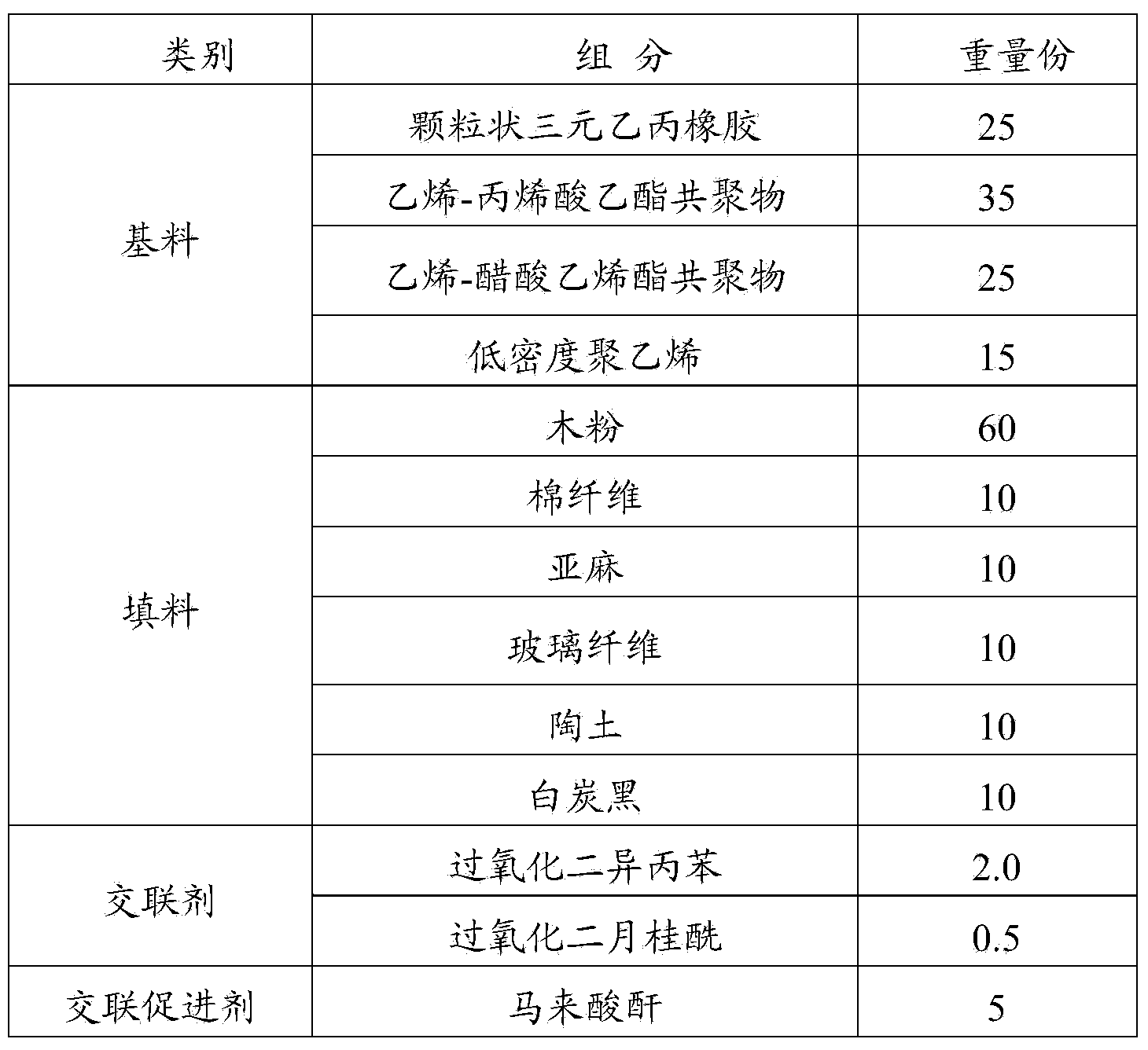

Embodiment 1

[0028]

[0029]

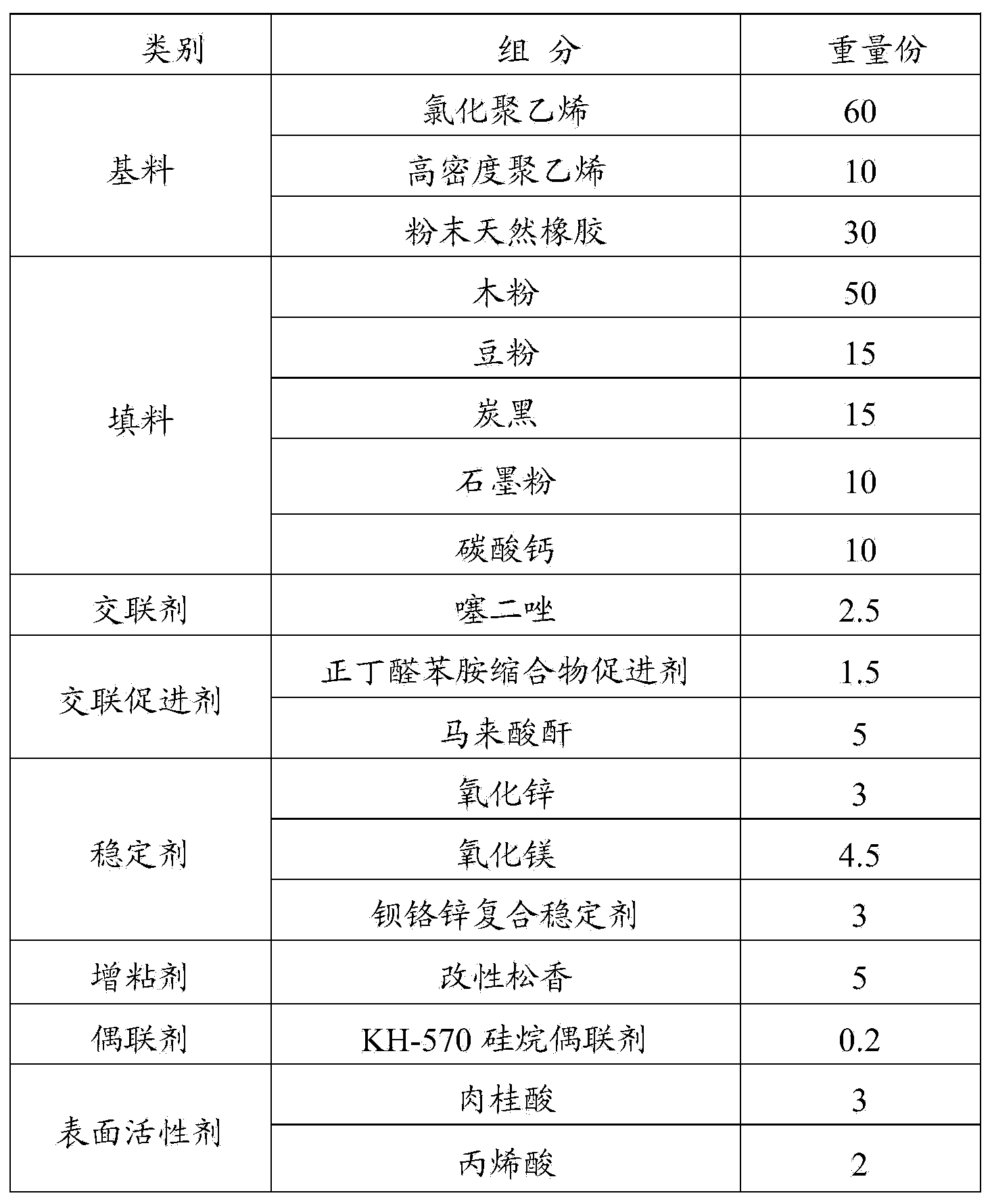

Embodiment 2

[0031]

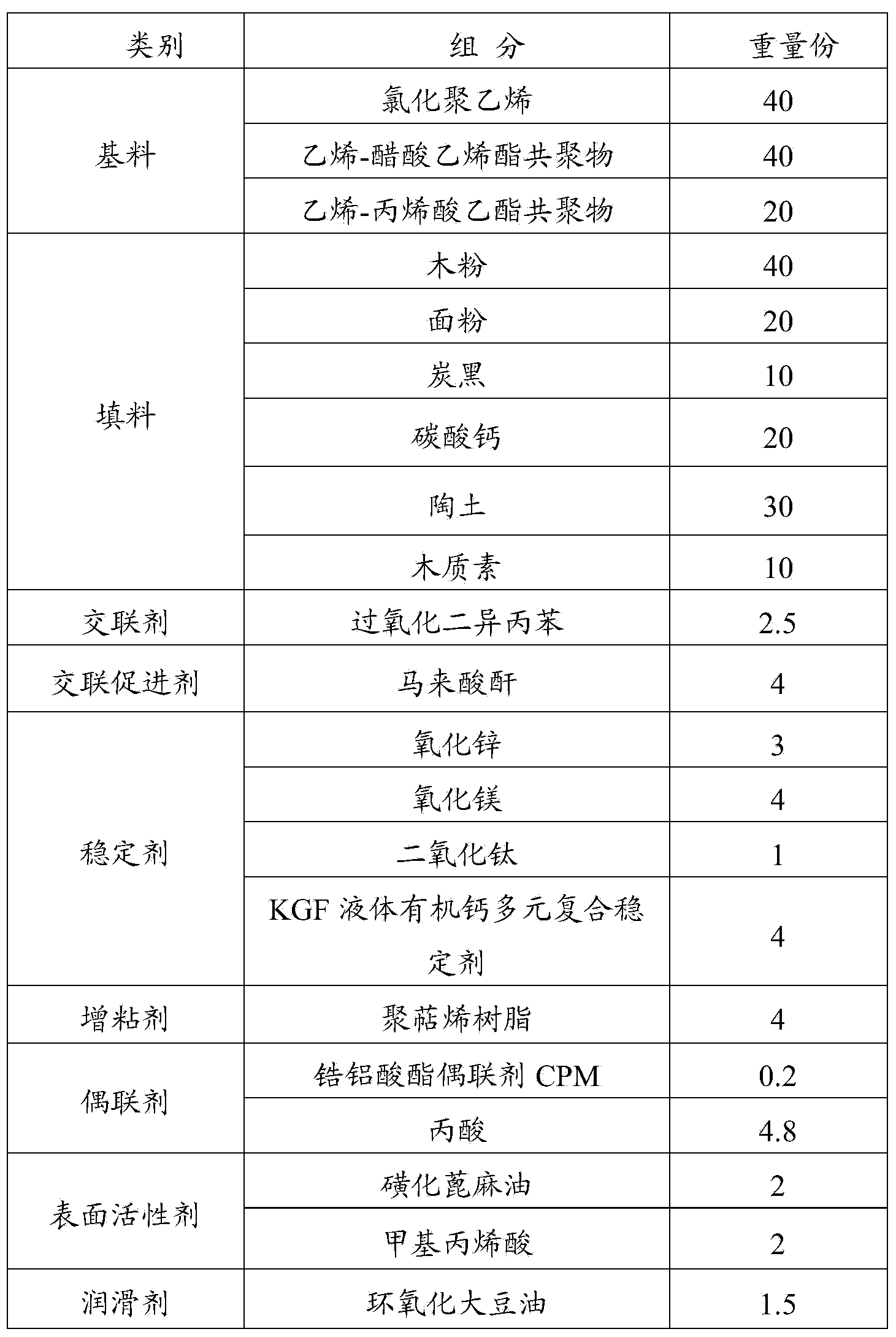

Embodiment 3

[0033]

[0034]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Bonding strength | aaaaa | aaaaa |

Login to View More

Abstract

A formaldehyde-free wood adhesive film comprises the following components in parts by weight: 100 parts of basic material, 1 to 300 parts of filler, 0.1 to 10 parts of a cross-linking agent, 0.01 to 10 parts of a cross-linking accelerator, 1 to 15 parts of a stabilizer, 1 to 20 parts of a tackifier, 0 to 10 parts of a coupling agent, 1 to 30 parts of a surfactant and 0.5 to 10 parts of a lubricant, wherein the basic material is at least two of chloride high polymer, chlorosulfonated high polymer, ethylene vinyl acetate copolymer, ethylene-ethyl acrylate copolymer, polyolefin and rubber; and the filler is at least one of organic filler, inorganic filler, compound filler and synthetic filler. The formaldehyde-free wood adhesive film contains no formaldehyde or organic volatile matter so as not to affect and harm the environment and the human health, and is excellent in environmental performance, convenient to use, transport and store and long in shelf life. The formaldehyde-free wood adhesive film is blended, modified and extruded into shape by a plastic extruding film technique.

Description

Technical field [0001] The invention relates to an aldehyde-free wood adhesive film. Background technique [0002] At present, the adhesives used in my country's plywood are basically thermosetting resins synthesized from formaldehyde, including urea-formaldehyde resins, phenolic resins, and melamine-formaldehyde resins (commonly known as trialdehyde resins). The amount of urea-formaldehyde resins is more than 80%. Due to the simple manufacture, low cost, convenient use, and wide application range of urea-formaldehyde resin adhesives, its leading position has been difficult to shake since its industrial production in 1957. With the development of social life, people's awareness and requirements for health and environmental protection continue to increase, and the shortcomings of formaldehyde-based resin adhesives are constantly being discovered and recognized. The main disadvantage of this type of adhesive is that the free formaldehyde in the resin, the formaldehyde released whe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J7/00C09J123/08C09J123/28C09J123/34C09J115/02C09J123/06C09J123/16C09J107/00C09J111/00C09J11/08C09J11/04

Inventor 杨学荣

Owner 杨学荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com