Fillet weld welding structure for K-type grooves of moderately-thick plate without back chipping and welding technology of fillet weld welding structure

A K-shaped groove and welding process technology, applied in welding/welding/cutting items, welding equipment, manufacturing tools, etc., can solve the problems of serious environmental pollution, high cost and low work efficiency in construction operations, and improve the construction of welders. Environment, welding quality improvement, effect of suppressing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

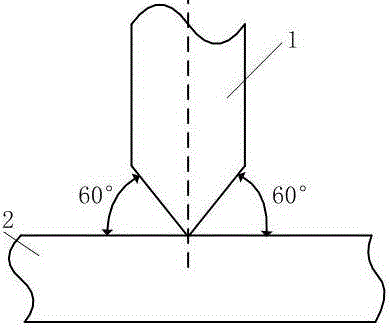

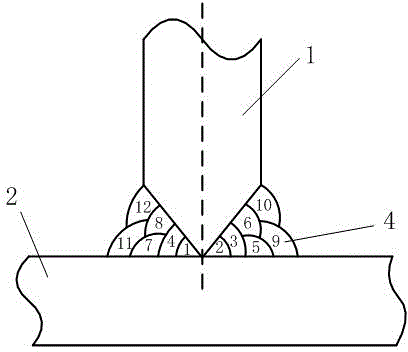

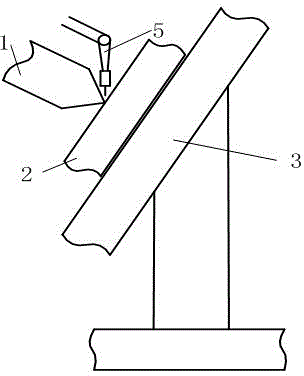

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] The labels in the drawings are as follows: 1 web, 2 bottom plate, 3 two-axis positioner, 4 welding bead, 5 robot arm with welding torch attached.

[0013] The fillet weld welding structure of the K-shaped groove of medium and thick plate with unclear root according to the present invention mainly includes a web and a bottom plate. The difference between it and the prior art is that both sides of the web have symmetrical grooves, When the web and the bottom plate are welded together, they fit closely without leaving any gaps. The angle range of the groove is 50°-60°. The medium and thick plate here refers to a steel plate with a thickness in the range of 16-32mm.

[0014] The difference between the fillet weld welding process of medium and thick plate K-shaped grooves with unclear roots and the prior art is that the welding process includes the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com