Final assembly method of ship shafting and rudder system

A technology of shafting and rudder system, applied in ship parts, ship construction, transportation and packaging, etc., can solve the problems affecting the speed and progress of ship construction, and the long service life of the dock, so as to reduce the construction period, improve the construction environment, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

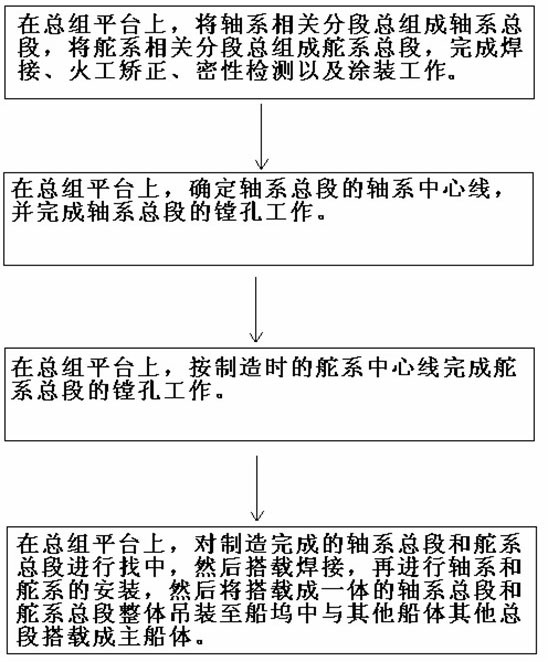

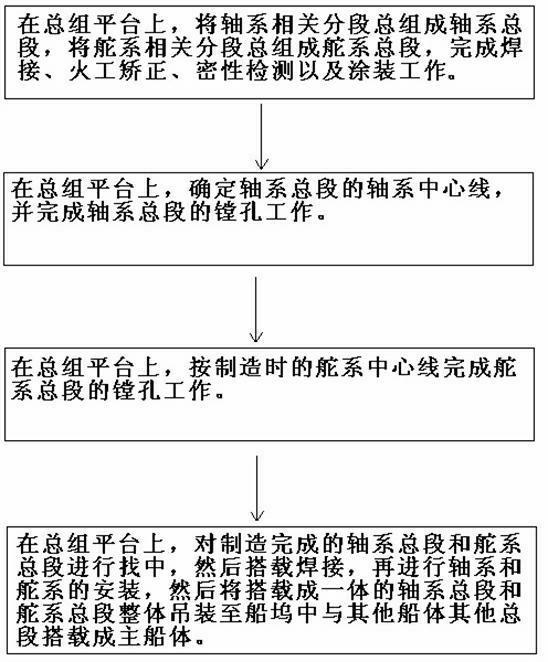

[0024] The general assembly method of the ship's shafting system and the rudder system of the present embodiment includes the following steps:

[0025] In the first step, on the general assembly platform, expand and assemble the relevant sections of the ship’s shafting system into the general shafting section, and expand the relevant sections of the ship’s rudder system into the general rudder section, and complete the general assembly of the shafting system respectively. Welding, pyrotechnic correction, cabin tightness test and painting work for the section and the rudder system general section; when the cabin tightness is tested, the cabin includes fuel oil release tank, lubricating oil drain tank, stern tube lubricating oil drain tank, Oil-water separation cabin and main engine lubricating oil circulation cabin.

[0026] In the second step, on the general assembly platform, inspect the complete shafting section until it fully meets the construction requirements, determine t...

Embodiment 2

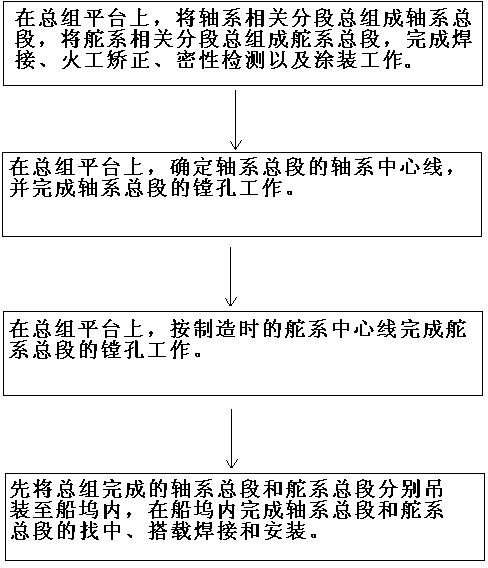

[0030] The general assembly method of the shafting system and the rudder system of the present embodiment includes the following steps:

[0031] In the first step, on the general assembly platform, expand and assemble the relevant sections of the ship’s shafting system into the general shafting section, and expand the relevant sections of the ship’s rudder system into the general rudder section, and complete the general assembly of the shafting system respectively. Welding, pyrotechnic correction, cabin tightness test and painting work for the section and the rudder system general section; when the cabin tightness is tested, the cabin includes fuel oil release tank, lubricating oil drain tank, stern tube lubricating oil drain tank, Oil-water separation cabin and main engine lubricating oil circulation cabin.

[0032] In the second step, on the general assembly platform, inspect the complete shafting section until it fully meets the construction requirements, determine the shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com