Curable epoxy resin-based adhesive compositions

A technology of epoxy resin and composition, which is applied in the direction of epoxy resin glue, adhesive type, natural rubber adhesive, etc., and can solve problems such as interference with curing adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0140] A series of adhesive compositions were prepared using the components listed in Table 1 (the amounts of each component are given in % by weight of the total composition), except that the amounts of the components used were the same in each example as follows:

[0141] 41.00% by weight Kaneka MX156 epoxy resin / core-shell rubber masterbatch (33% by weight core-shell rubber particles; Kaneka CO.);

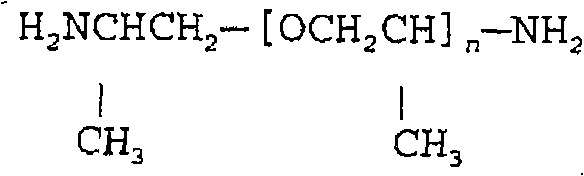

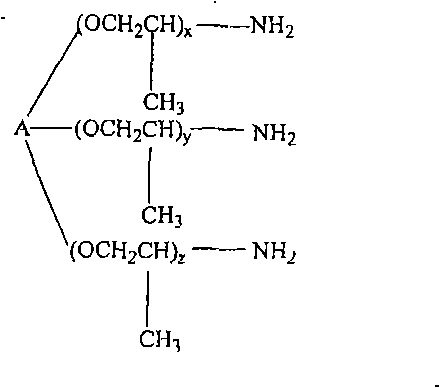

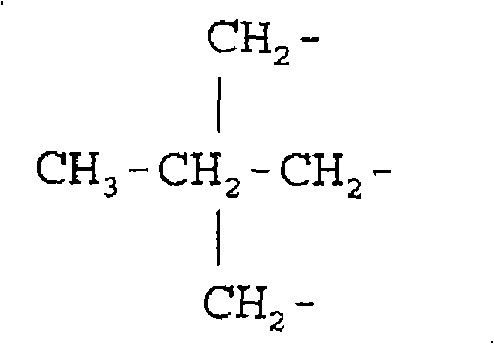

[0142] 15.00% by weight epoxy resin / amine terminated polyether reaction product prepared according to US Patent No. 6,015,865;

[0143] 9.00% by weight Zeon F351 core-shell rubber particles (Nippon Zeon Chemicals);

[0144] 2.00% by weight Adeka Resin EP-49-10N (epoxy equivalent weight = 225; 100% solids; Asahi Denka Kogyo);

[0145] 3.00% by weight of a carboxylic anhydride / amine terminated polyether adduct, which is further reacted with an epoxy resin, prepared according to US Patent No. 6,884,854 or US Patent Application Publication No. US 2005-0215730;

[0146] 1.50% by we...

Embodiment 16

[0159] 2 DY965 CH polyurethane, believed to be prepared according to Example 16 of US Patent 5,278,257 (Huntsman Advanced Materials)

[0160] 3MESAMOLL Sulfonate Plasticizer (Bayer)

[0161] 4 tricresyl phosphate

[0162] 5 AMICURE CG1200 Dicyandiamide (Air Products)

Embodiment 7

[0164] Prepare an adhesive comprising the following components:

[0165] 53.66 wt% epoxy / core-shell masterbatch (Kaneka MX156, containing 25 wt% core-shell rubber particles; Kaneka Co.);

[0166] 15.00% by weight epoxy resin / amine terminated polyether reaction product prepared according to US Patent No. 6,015,865;

[0167] 9.00% by weight Zeon F351 core-shell rubber particles (Nippon Zeon Chemicals);

[0168] 4.00% by weight MESAMOLL sulfonate plasticizer (Bayer);

[0169] 2.00% by weight Adeka Resin EP-49-10N (epoxy equivalent weight = 225; 100% solids; Asahi Denka Kogyo);

[0170] 3.00% by weight of a carboxylic anhydride / amine-terminated polyether adduct, which is further reacted with an epoxy resin, prepared according to US Patent No. 6,884,854 or US Patent Application Publication No. US 2005-0215730;

[0171] 0.64% by weight WINGSTAY L antioxidant (Eliokem);

[0172] 1.50% by weight GARAMITE 1958 mixed mineral thixotrope (Southern Clay);

[0173] 1.00% by weight CARD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com