Adhesive tape with textile holder for cable bandaging

A tape and carrier technology, applied in the direction of fabrics, textiles, adhesives, etc., can solve the problem of reduced noise suppression ability of mesh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

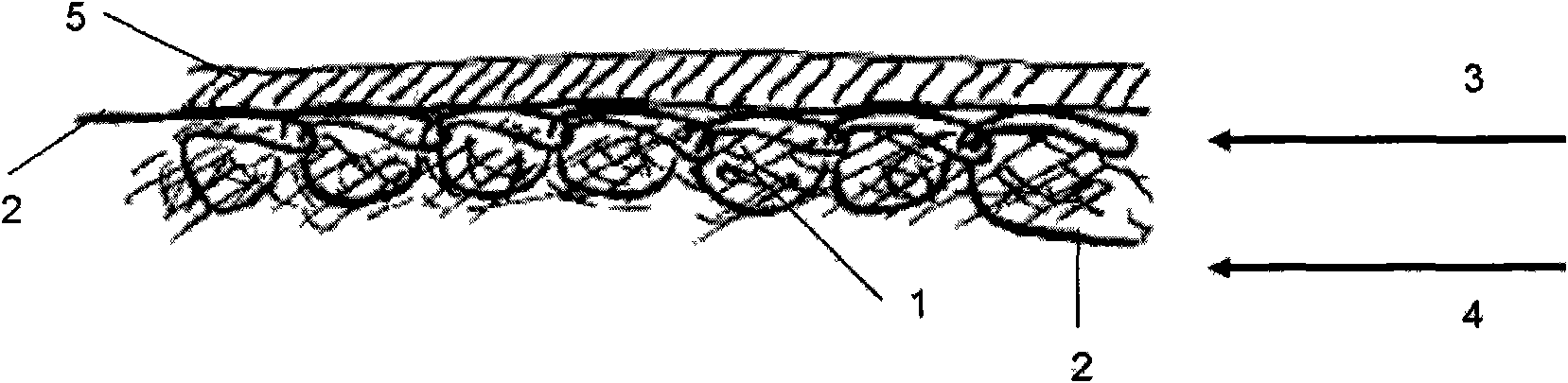

[0118] Example 1.) shows adhesive tapes according to the invention, the carrier of which was produced by bottom stitch-bonding a pre-reinforced web. The tape exhibits application-compatible characteristics for cable wrapping: despite the small number of stitching yarns and the large stitch length, there is little fiber extraction from the back of the web (to the steel after unwinding from the roll). As evidenced by the high bonding strength), the mechanical data meets the requirements, no edge warping, can be torn by hand, and the noise suppression is sufficient. Lateral flexibility, expressed as transverse flexural stiffness, is higher than Example A.

[0119] For examples 2.) and 3.), the base web used was a spunbond web; here again, application-compatible properties are obtained despite a small number of stitching yarns and / or a large stitch length, And the tape is very soft in all directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com