Steel tube bundle-corrugated steel plate concrete combined column

A technology of corrugated steel plates and steel tube bundles, applied in the direction of columns, pier columns, pillars, etc., can solve problems such as buckling, inability to give full play to the combined effect of steel and concrete, and failure to achieve the combined effect of steel tubes and concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

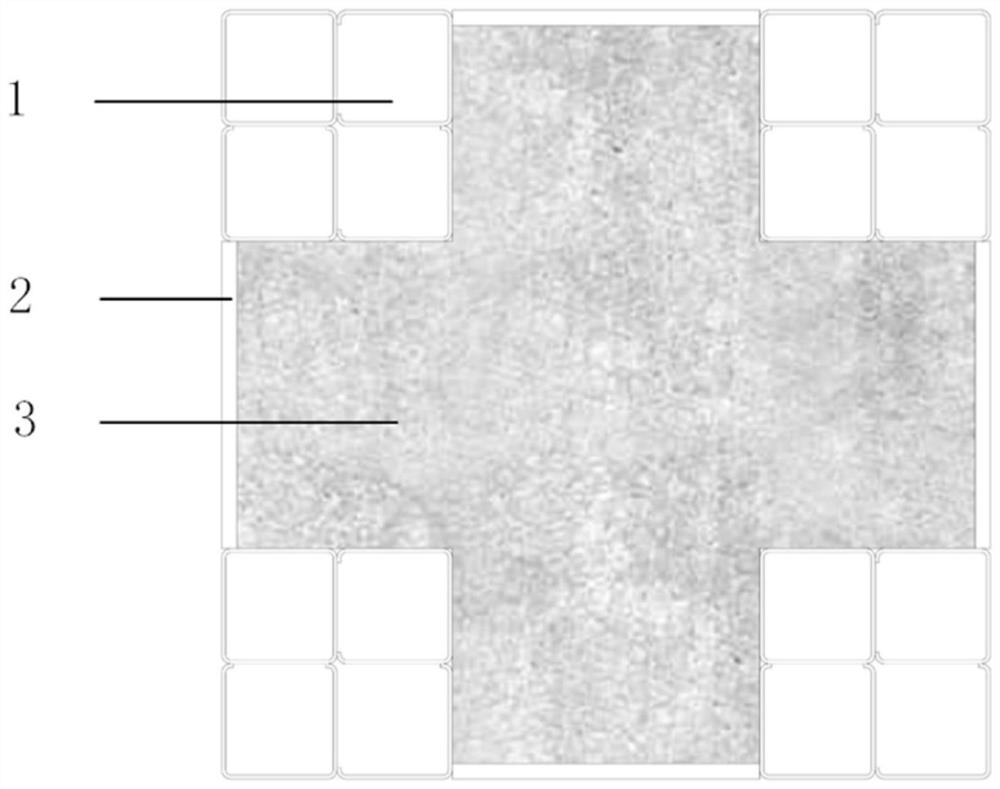

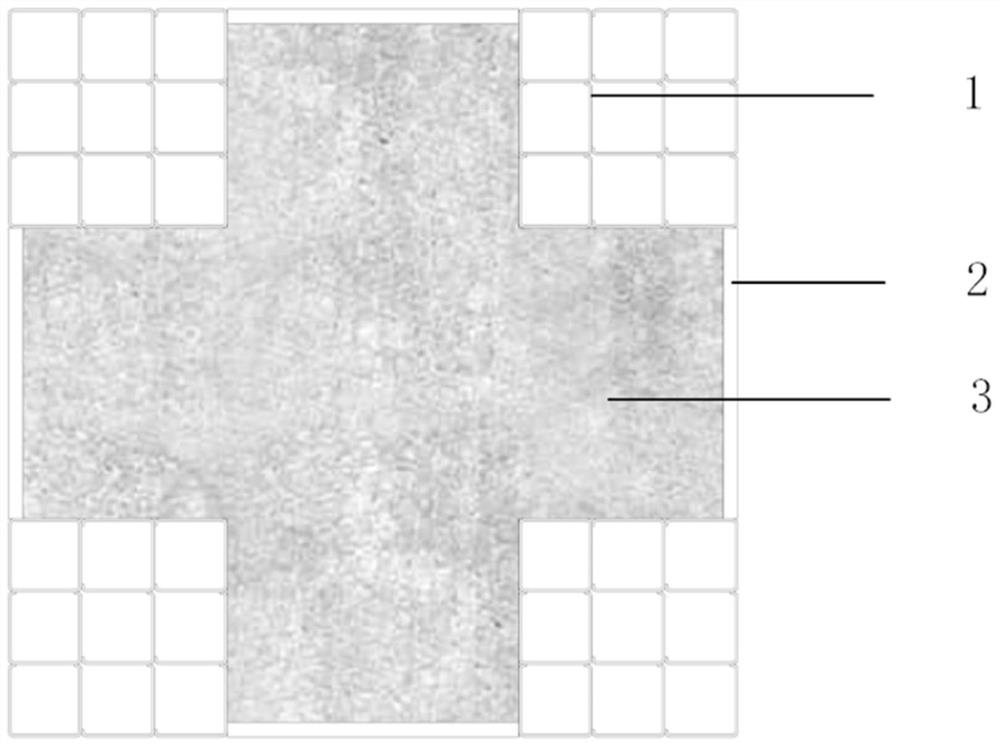

[0025] Such as figure 1 with 2 As shown, a steel tube bundle corrugated steel plate concrete composite column includes a composite column body, and the composite column body includes a steel tube bundle 1 , corrugated steel plate 2 and concrete 3 . The steel pipe bundle 1 is arranged vertically, and the corrugation on the corrugated steel plate 2 is perpendicular to the steel pipe bundle 1 . The corrugated steel plates 2 are located between the steel pipe bundles 1, and the sides of the steel pipe bundles 1 and the corrugated steel plates 2 are connected end to end to form a columnar body.

[0026] The cross section of the composite column body is rectangular, and the steel pipe bundles 1 are located at the four corners of the rectangle. The cross-section of the steel pipe bundle 1 is also rectangular, and the cross-sectional rectangle of the steel pipe bundle 1 is the four corners of the cross-sectional rectangle of the composite column body. The steel pipe bundle 1 includ...

Embodiment 2

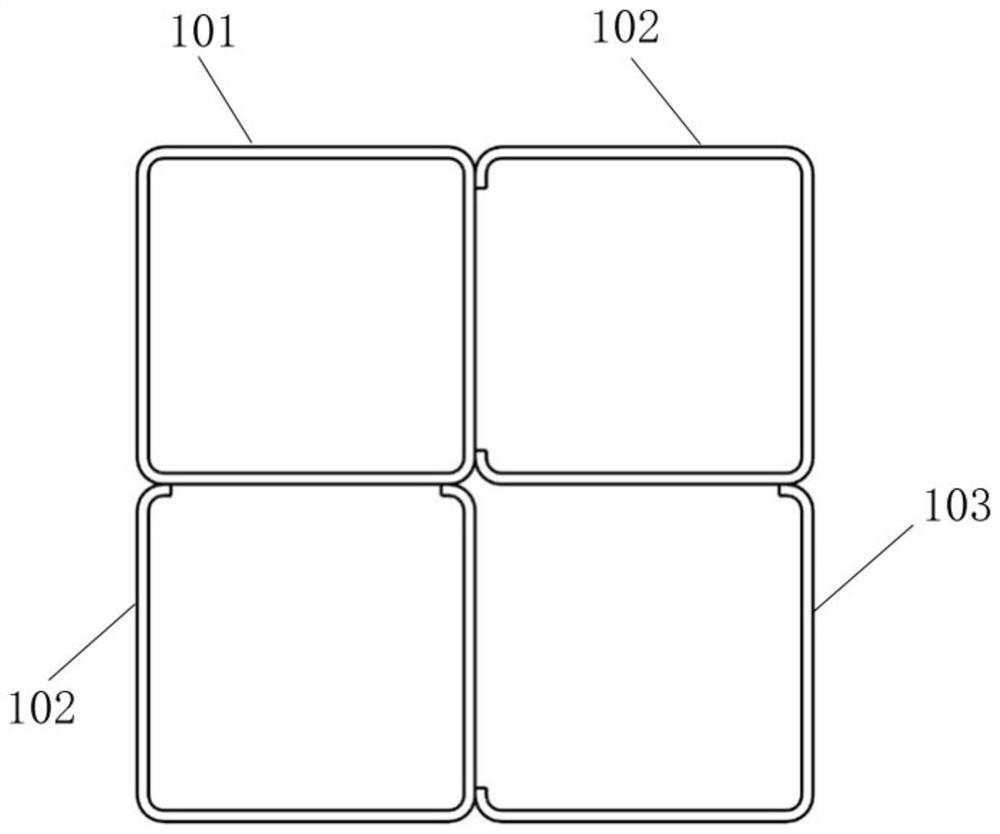

[0030] Such as Figure 3-5 As shown, the difference between this embodiment and Embodiment 1 is that the steel pipe bundle of this embodiment is welded by one rectangular steel pipe 101 , four C-shaped steels 102 and four angle steels 103 . Four angle steels 103 are welded together to form an outer angle, and four C-shaped steels 102 are welded together in pairs to form a side angle between the inner and outer angles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com