Automatic moving trolley with vertical and horizontal direction steering function and steering method

An automatic moving, vertical and horizontal technology, applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of non-replaceable curved formwork units, small application range of tunnel lining trolleys, and unfavorable on-site construction, etc. Promote the effect of convenient use, installation and operation, and less space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

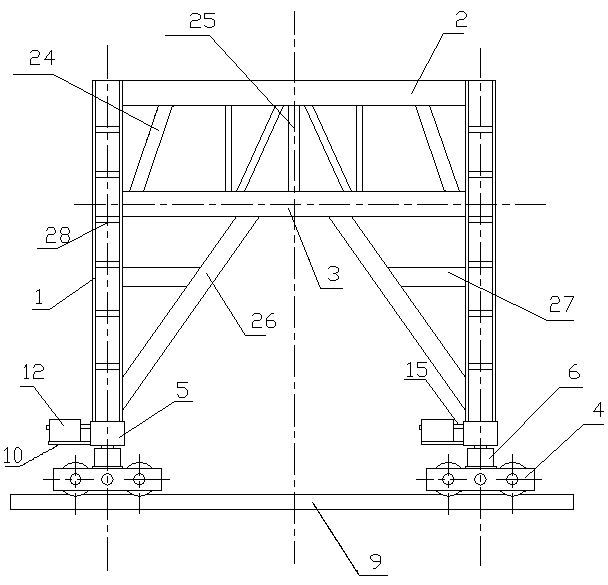

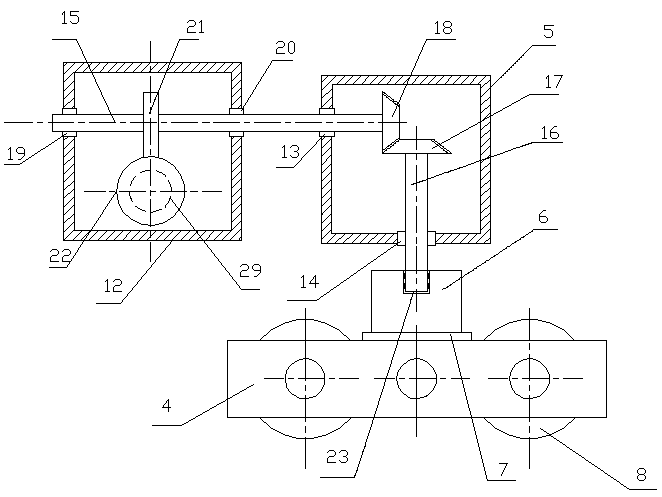

[0024] An automatic mobile trolley with vertical and horizontal steering functions, its composition includes: vertical support steel frame 1, horizontal support steel frame A2, horizontal support steel frame B3 and limit wheel connecting plate 4, the two vertical The bottom of the supporting steel frame is equipped with a gearbox A5, the gearbox A is connected to the bogie 6, the bottom of the bogie is welded to the horizontal fixed frame 7, and the bottom of the horizontal fixed frame is welded on two Above the above-mentioned spacer wheel connection plate, spacer wheel 8 is installed between two described spacer wheel connection plates, and described spacer wheel is arranged on the top of slideway 9, and described vertical support steel frame A mounting frame 10 is welded on the mounting frame, and an asynchronous motor 11 is installed on the mounting frame through a bolt assembly. The output shaft 29 of the asynchronous motor is connected to the gearbox B12, and the gearbox ...

Embodiment 2

[0026] According to the automatic mobile trolley with vertical and horizontal steering functions described in Embodiment 1, the side of the gearbox A is provided with a bearing seat A13, and the bottom is equipped with a bearing seat B14, and a horizontal shaft is inserted into the bearing seat A 15. A vertical shaft 16 is inserted into the bearing seat B, a horizontal bevel gear 17 is welded at the end of the vertical shaft, and a vertical bevel gear 18 is welded at the end of the horizontal shaft. The horizontal bevel gear and the vertical bevel gear are arranged in the gearbox A and mesh with each other.

Embodiment 3

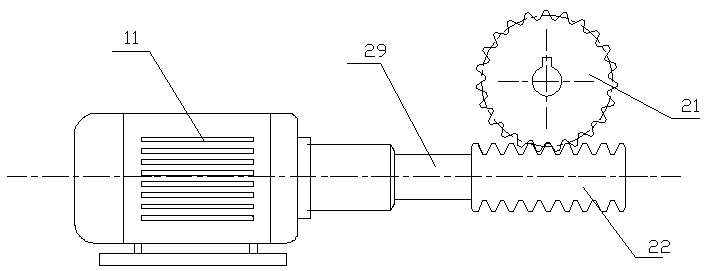

[0028] According to the automatic mobile trolley described in Embodiment 1 or 2 with vertical and horizontal steering functions, the two sides of the gearbox B are respectively provided with a bearing seat C19 and a bearing seat D20, and the bearing seat C and the The horizontal rotating shaft is inserted into the bearing seat D, the gear box B has a worm gear 21 and a worm 22, and the horizontal rotating shaft is inserted into the circular hole of the worm gear and meshed with the worm gear, The worm is inserted on the shaft surface of the output shaft of the asynchronous motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com