Shell, electronic device using the same and manufacturing method thereof

A technology of electronic device and manufacturing method, which is applied in the direction of electrical equipment shell/cabinet/drawer, electronic equipment, lamination device, etc., can solve the problems of easy breakage, long manufacturing cycle, unable to meet the requirements of signal reception and transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

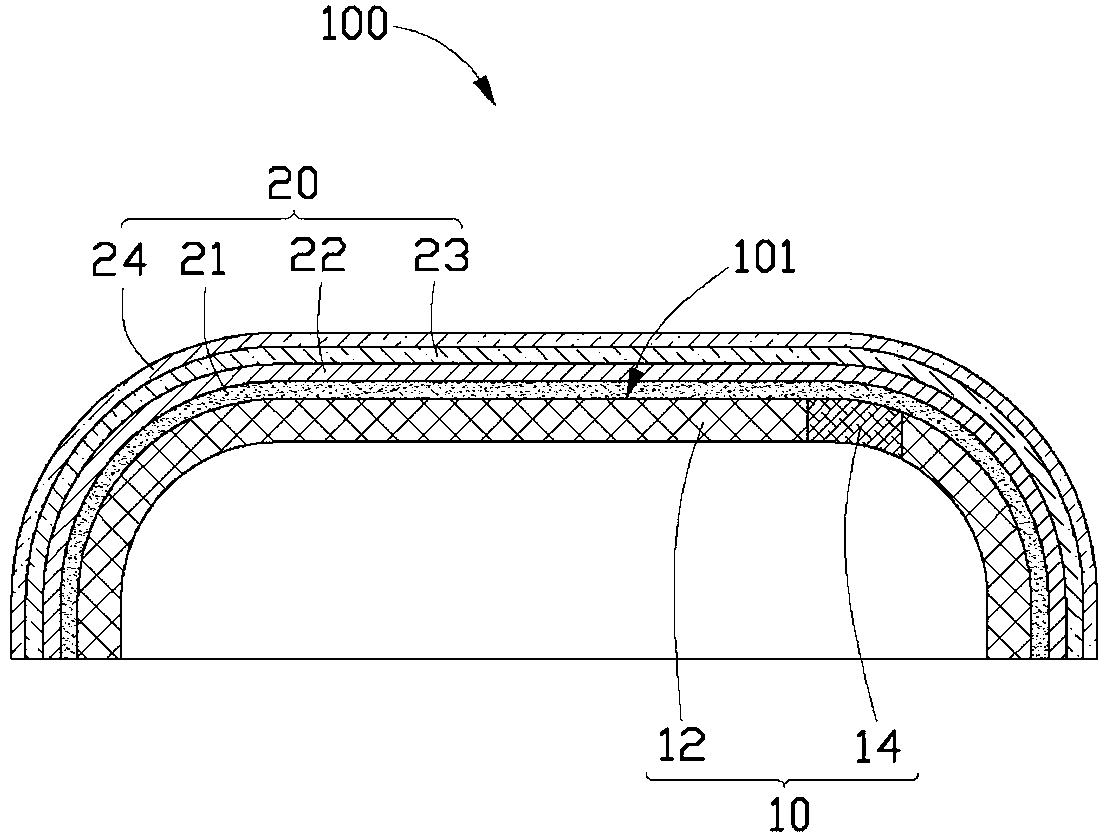

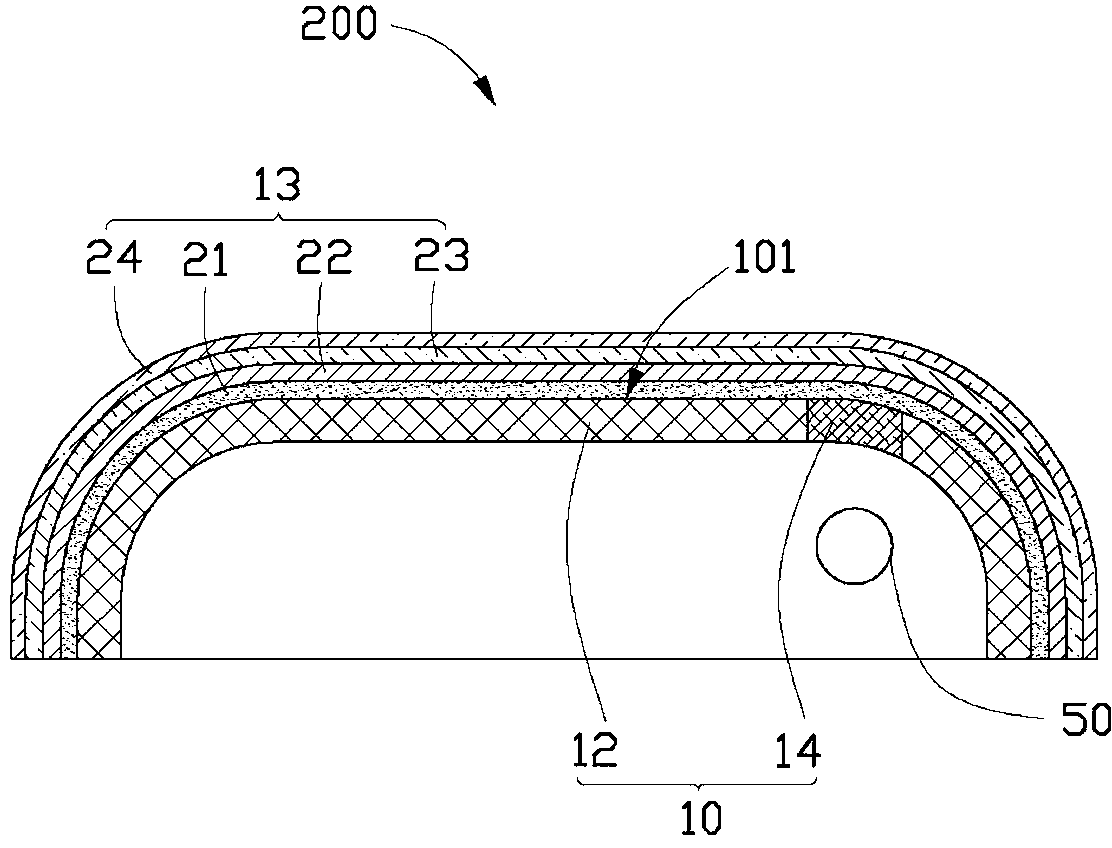

[0023] see figure 1 , the housing 100 of the preferred embodiment of the present invention includes a base 10 and a decoration layer 20 formed on the base 10 .

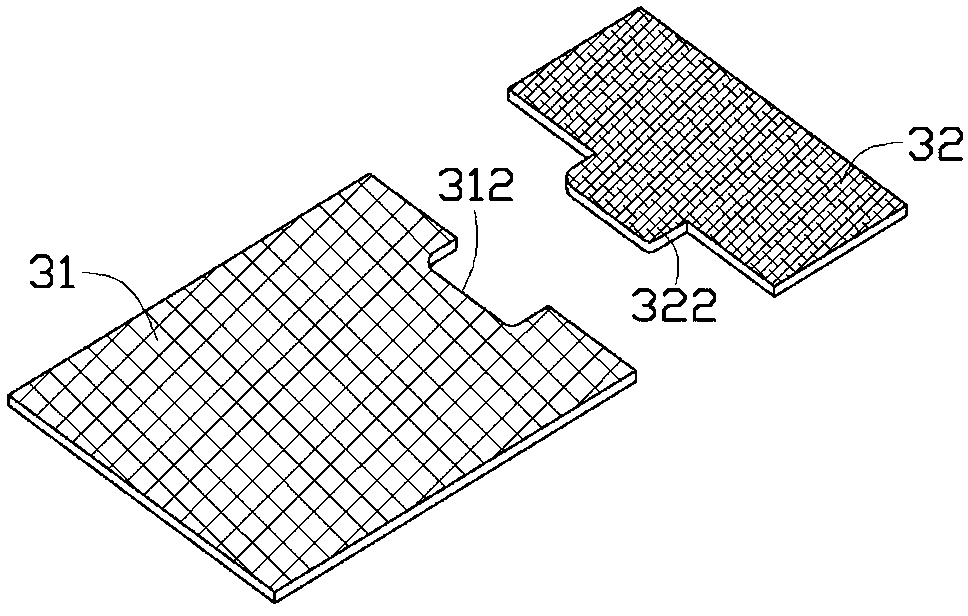

[0024] The base body 10 includes a first portion 12 and a second portion 14 joined to the first portion 12 . The first portion 12 and the second portion 14 jointly form the outer surface 101 of the base body 10 . Both the first part 12 and the second part 14 are formed by a braided fiber layer impregnated with resin, and the resin is formed on the surface and inside of the braided fiber layer. The braided fiber layers of the first part 12 are formed from carbon fibres. The braided fiber layer of the second portion 14 is formed of non-conductive glass fibers. The surface of the base body 10 is formed with staggered three-dimensional weaving lines.

[0025] The resin is a transparent or translucent resin, and may be one or a combination of epoxy resin, polycarbonate resin, and a mixture of polyamide resin and glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com