D-column upper end joint structure

A technology of joint structure and welding place, which is applied in the field of joint structure at the upper end of D-pillar, and can solve the problems of weak welding, poor forming process of parts, and low utilization rate of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

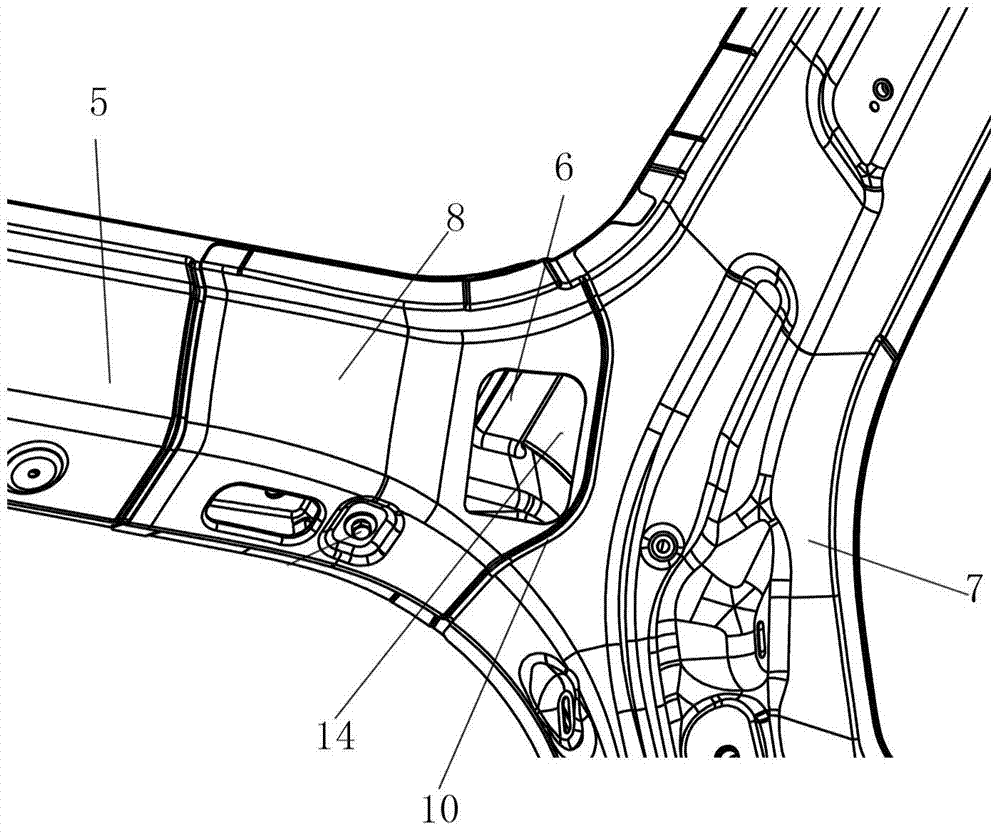

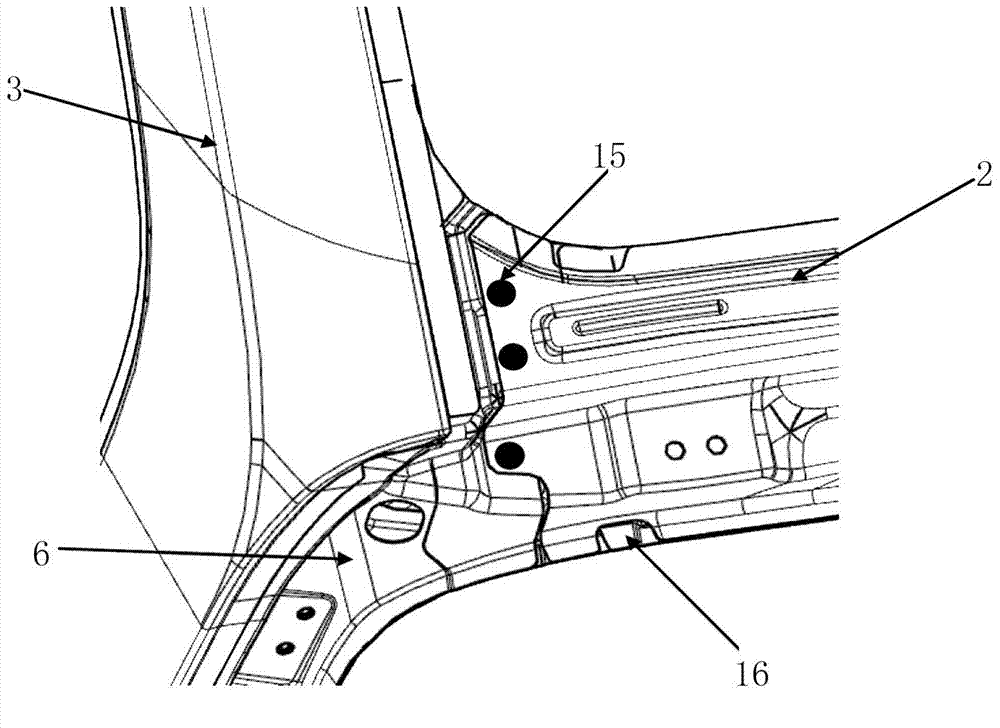

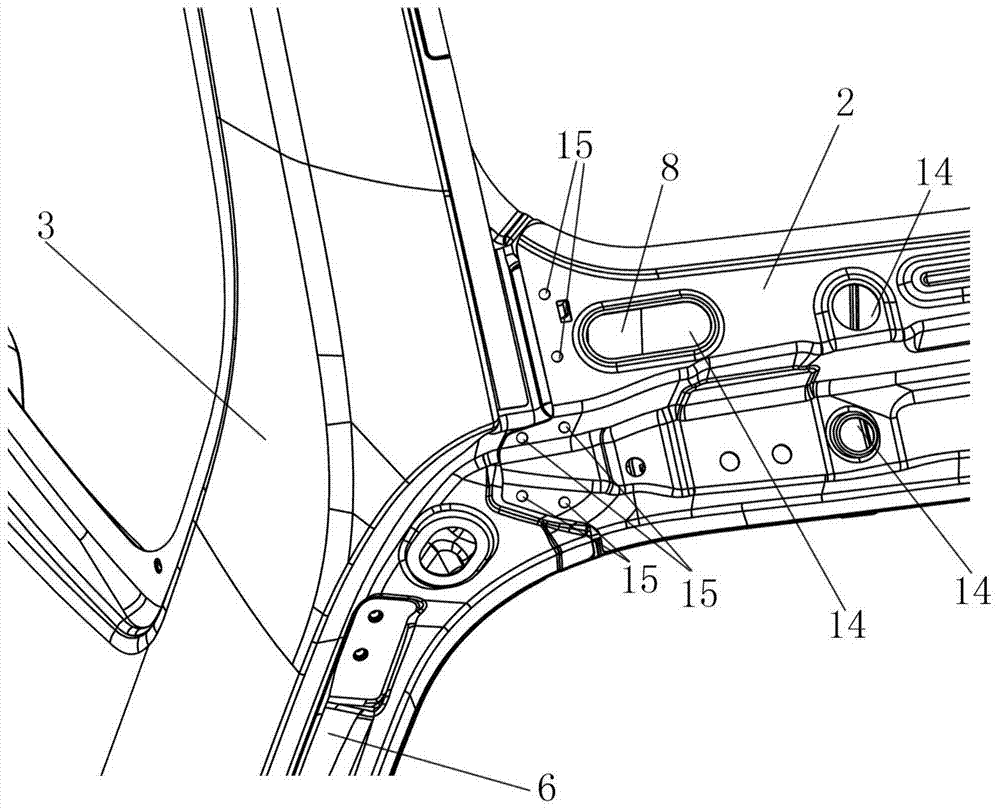

[0029] The following with attached Figure 2 to Figure 7 A D-pillar upper end joint structure of the present invention will be further described in detail.

[0030] A D-pillar upper end joint structure of the present invention, please refer to Figure 2 to Figure 7 , including roof 1, roof rear beam outer panel 2, roof rear beam inner panel 5, D-pillar upper reinforcement panel 8, rear side wall outer panel 3, D-pillar upper outer panel 6 and rear side wall outer panel 3, The rear side wall outer panel 3 is welded and fixed to the D-pillar upper outer panel 6, the edge of the reinforcement plate 8 on the D-pillar is dislocated from the edge of the rear side wall inner panel 7, and the reinforcement on the D-pillar The plate 8 is L-shaped, with a circular arc-shaped transition section in the middle, an extension 9 extends from the upper part of the D-pillar upper reinforcement plate 8 to one side, and a concave arc-shaped bend is provided on the top of the rear side wall inner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com