Centrifugal casting runner and centrifugal casting system

A technology of centrifugal casting and sprue, which is applied in the field of casting processing of auto parts, which can solve the problems of prolonging the molding cycle, uneven distribution of casting liquid, internal stress of cylinder liner, etc., and achieve the effect of ensuring rapid distribution and shortening casting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

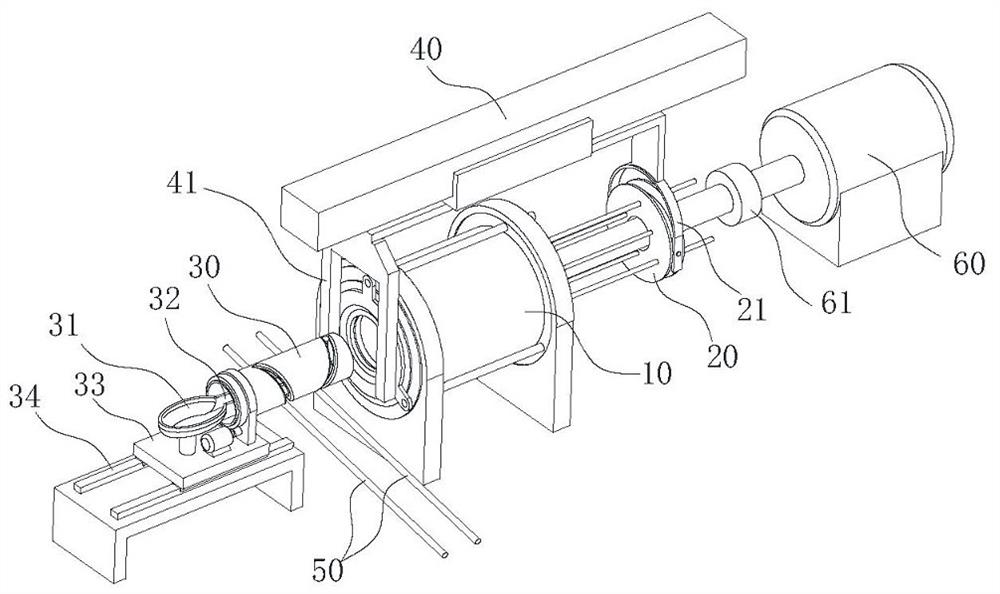

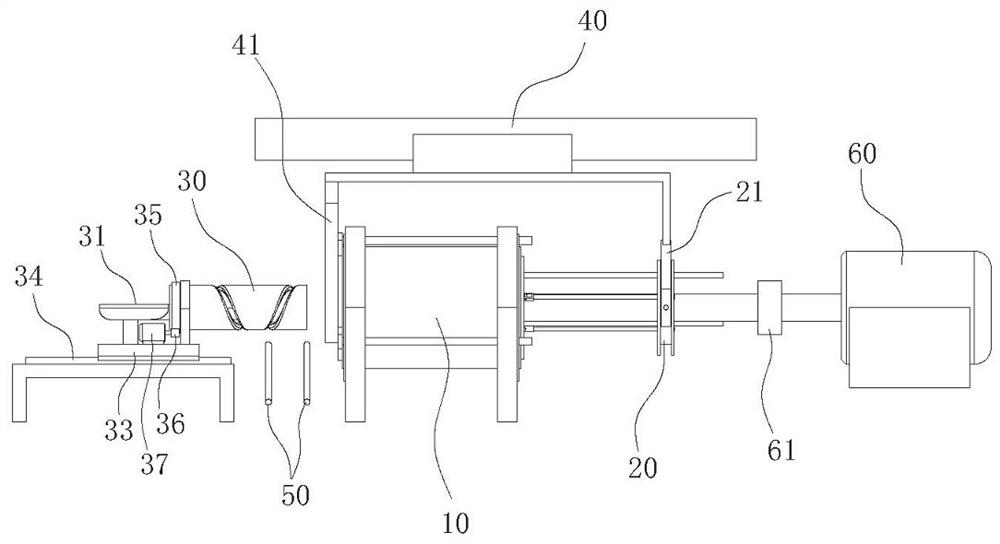

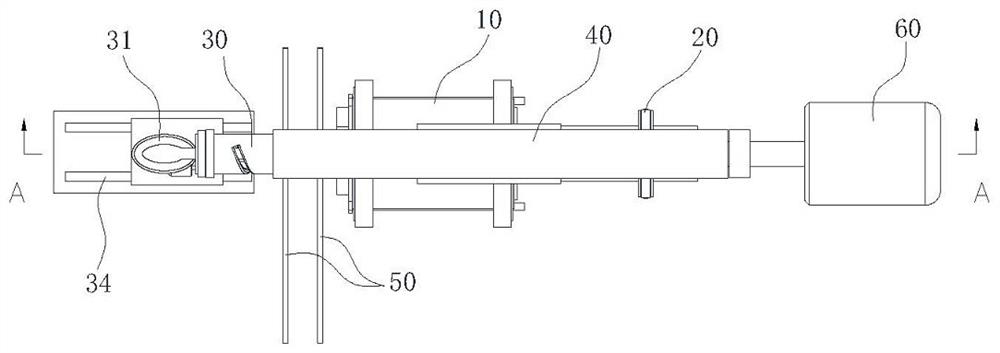

[0025] Such as Figure 1-4 As shown, a cylinder liner centrifugal casting system includes a casting unit and a centrifugal unit. The centrifugal unit includes a cylindrical mold body 10 rotatably arranged along a horizontal axis. The first end of the cylindrical mold body 10 is provided with a first end plate 11. The second end of the cylindrical mold body 10 is provided with a second end plate 12, and the center of the second end plate 12 is provided with a casting channel, and the casting unit is located outside the casting channel, and the casting unit is used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com