A heat dissipation device and a heat dissipation method of a power supply isolation module

A power isolation and heat dissipation device technology, which is applied in the direction of electrical components, electrical equipment structural parts, modification through conduction heat transfer, etc., can solve the problems that cannot meet the requirements of heat dissipation, high heat flux density, large thermal resistance, etc., and achieve faster Heat loss, good thermal conductivity, effect of increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

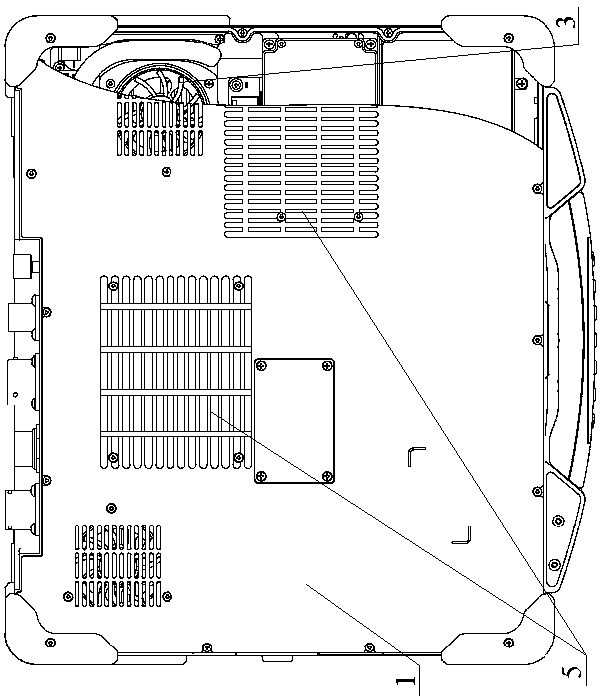

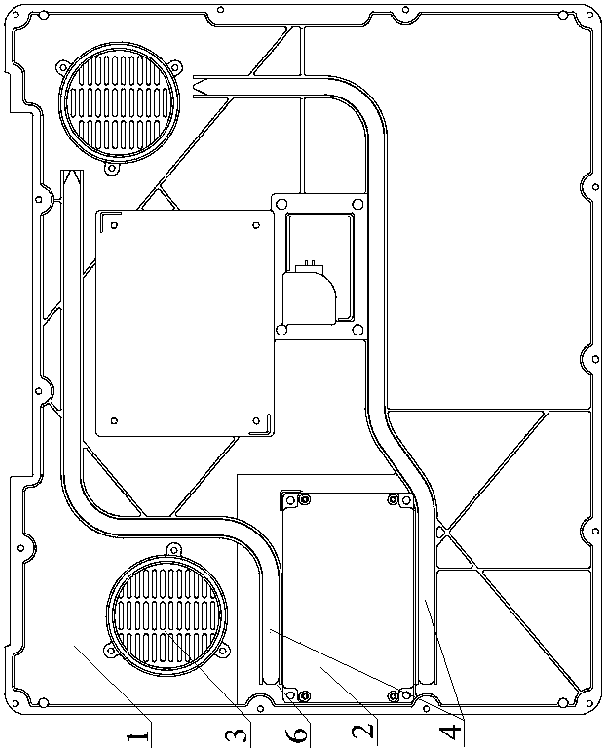

[0029] Such as figure 1 and figure 2 As shown, the power isolation module heat dissipation device of the present invention includes a chassis, a power isolation module 2 , a fan 3 , two heat dissipation pipes 4 and heat dissipation fins 5 .

[0030] The power isolation module 2 and the fan 3 are respectively fixed on the chassis bottom shell 1 . Two grooves 6 are opened on the bottom case 1 of the chassis, and two heat dissipation pipes 4 are respectively welded in the grooves 6 . Both cooling pipes 4 are in contact with the power isolation module 2 . The air outlet of the cooling pipe 4 corresponds to the air inlet of the fan 3 . Both the power isolation module 2 and the chassis bottom shell 1 are made of aluminum alloy. Radiating fins 5 are fixed on the outer side of the chassis bottom shell 1 , and the heat dissipation direction of the cooling fins 5 is consistent with the airflow direction of the air inlet of the fan 3 . The cooling fins 5 are disconnected from the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com