Heat radiating device

A technology of heat sink and heat sink, applied in cooling/ventilation/heating transformation, instrument cooling, instrument and other directions, can solve the problems of low temperature, insufficient heat absorption and heat dissipation of heat sink, insufficient heat dissipation of electronic components, etc. To achieve the effect of improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

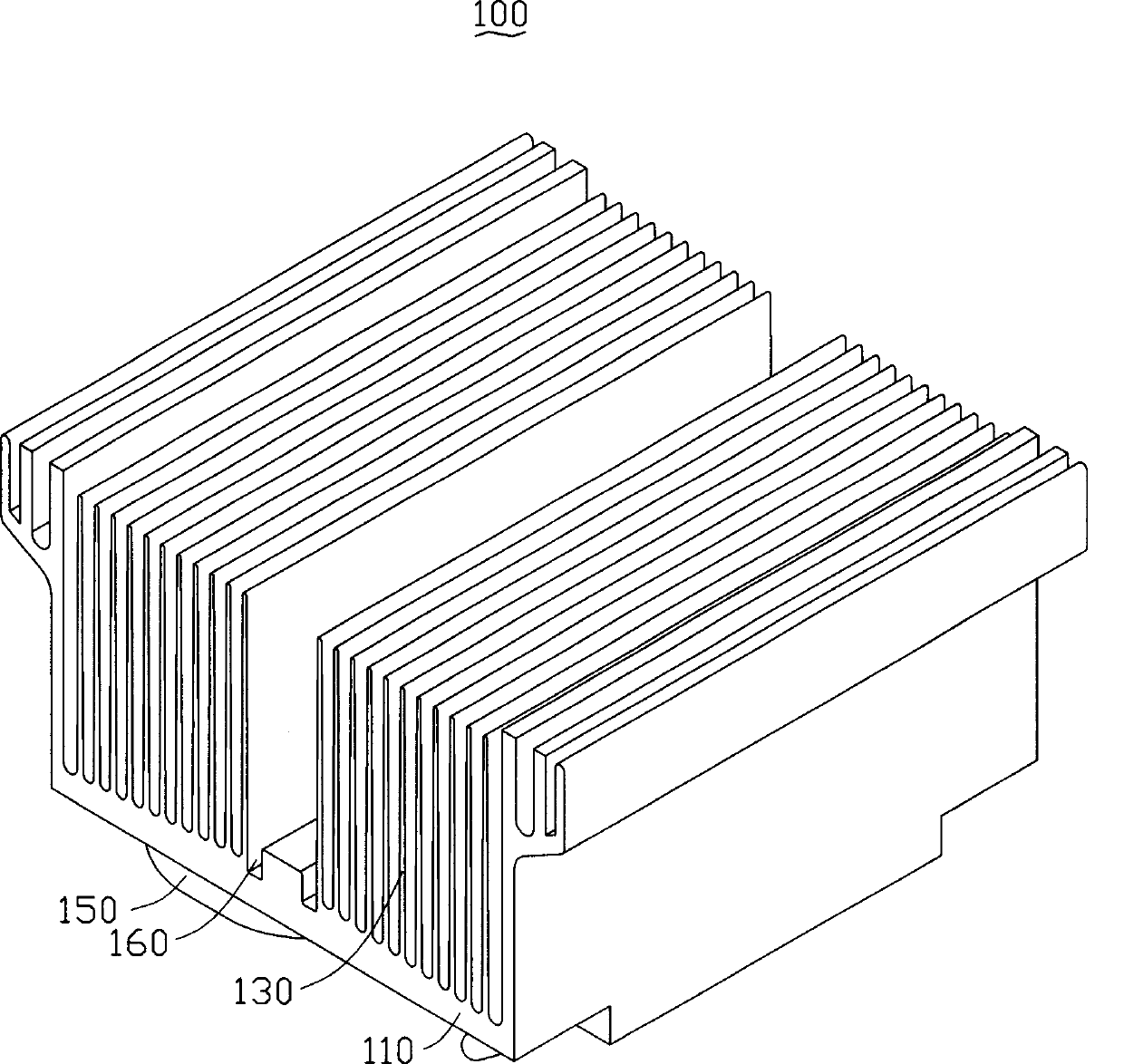

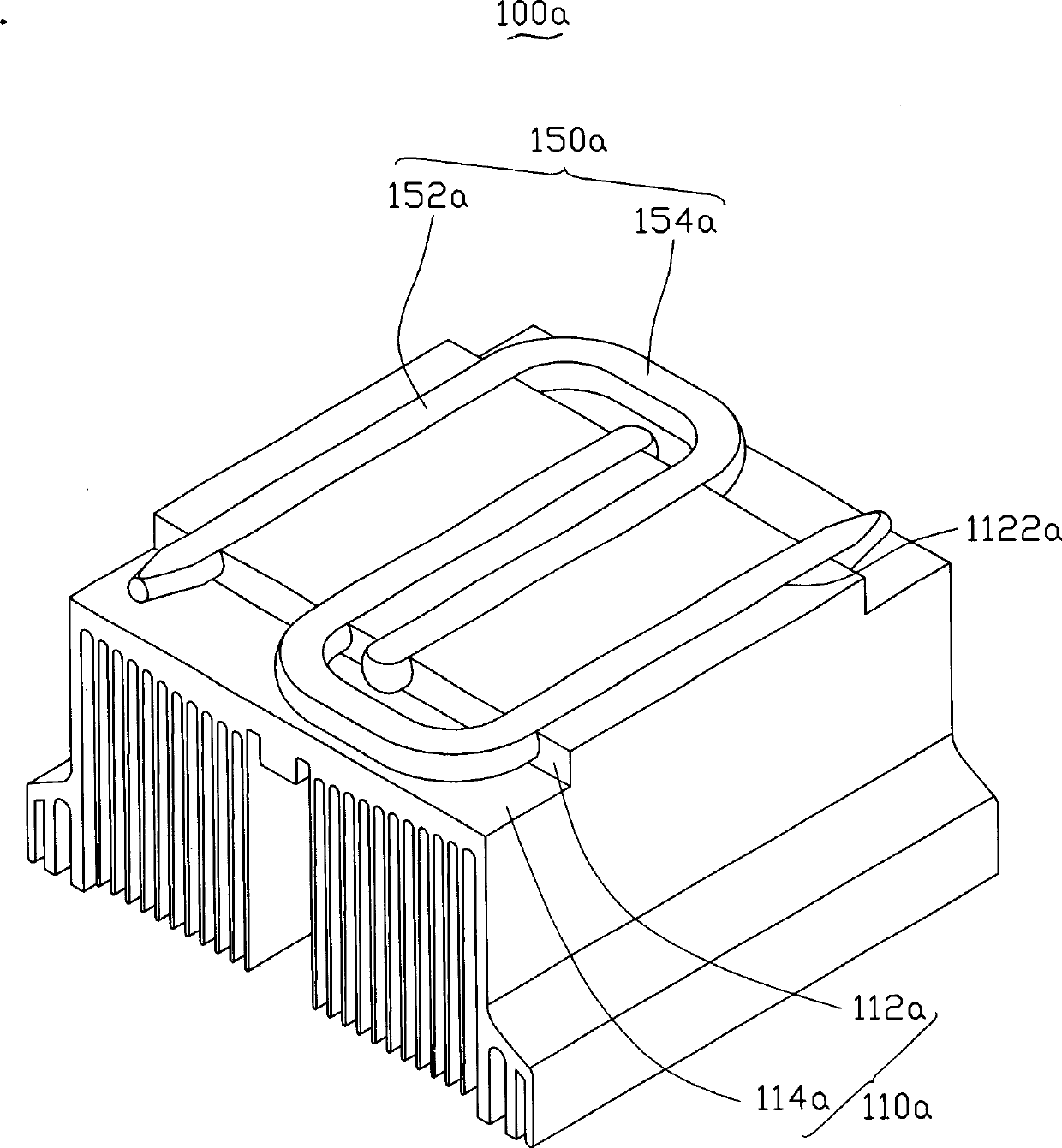

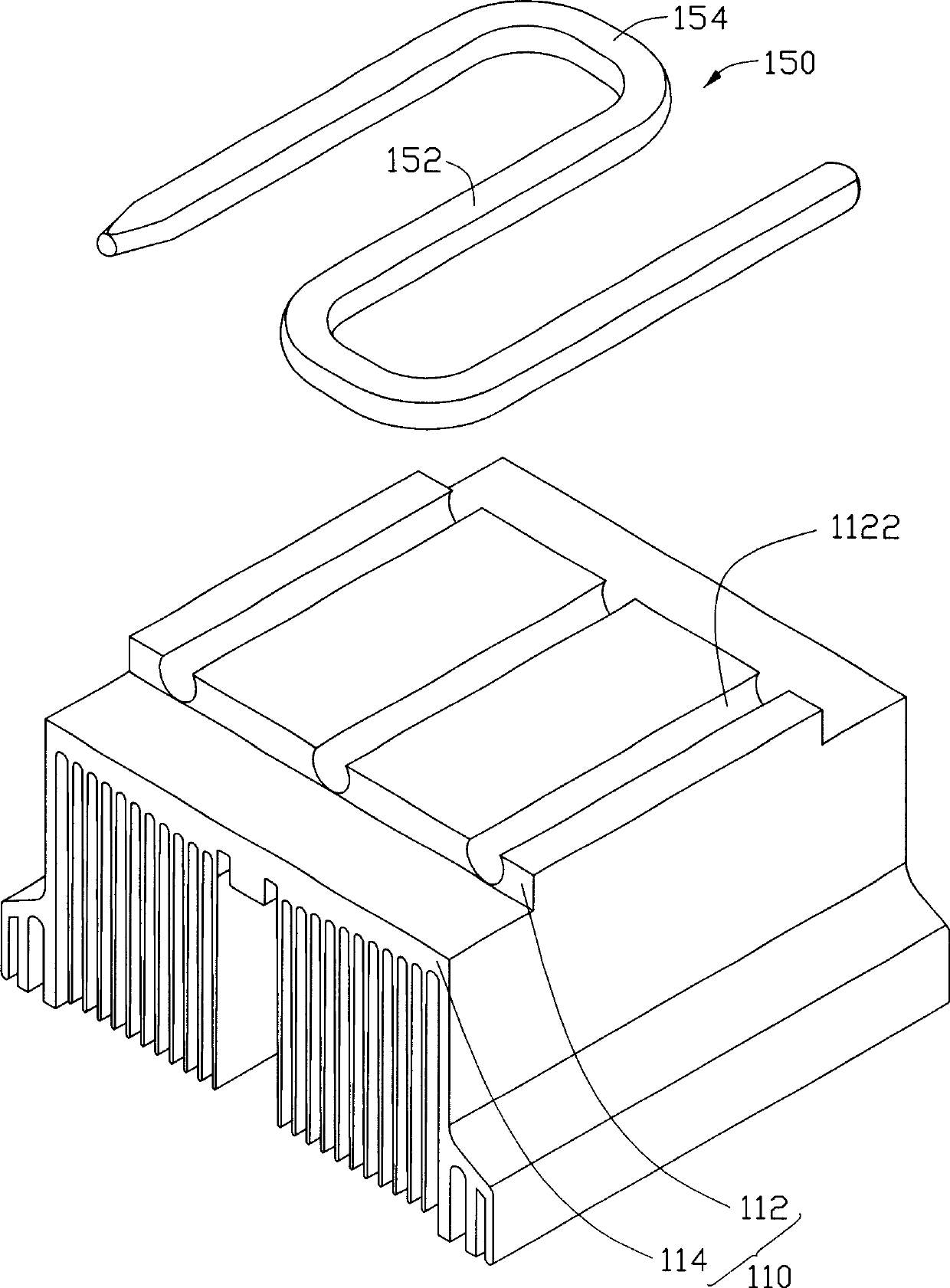

[0012] Figure 1 to Figure 3 Shown is the first embodiment of the heat sink of the present invention. The heat dissipation device 100 includes a base 110, a plurality of heat sinks 130 arranged on the base 110, and an S-shaped heat pipe 150 embedded at the bottom of the base 110.

[0013] The base 110 is made of materials with good thermal conductivity such as aluminum and copper. The base 110 includes two parts, namely a first heat conducting plate 114 and a second heat conducting plate 112 protruding from the middle of the first heat conducting plate 114. The first heat-conducting plate 114 is connected to the heat sink 130, and the bottom surface of the second heat-conducting plate 112 is usually in contact with electronic components such as a central processing unit (not shown) to absorb the heat generated by the electronic components.

[0014] The contours of the first heat conducting plate 114 and the second heat conducting plate 112 are rectangular, and the width of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com