Diaphragm with dual-effects of reflecting and transmission and manufacturing method thereof

A technology with dual functions and production methods, applied in optics, instruments, optical components, etc., can solve problems such as low reflective performance and short outdoor service life, and achieve the effects of delaying aging speed, prolonging recognition effect, improving reflective performance and warning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

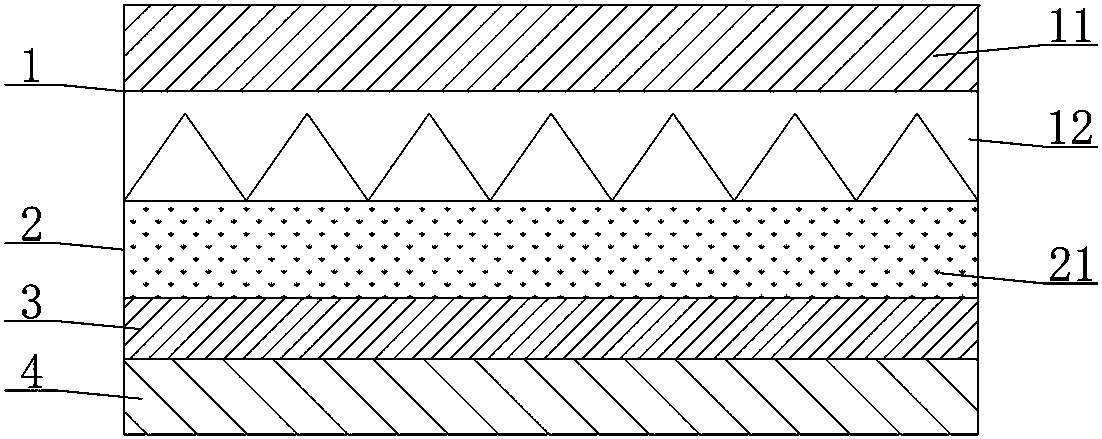

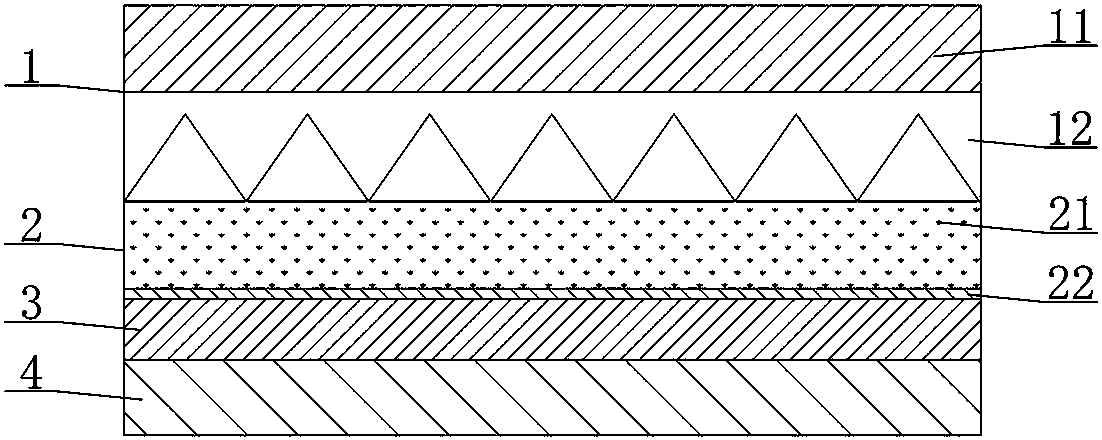

[0068] Such as figure 1 , figure 2 As shown, a diaphragm with dual effects of reflection and transmission includes a reflective layer 1, a pressure-sensitive adhesive layer 3, and a release layer 4. The lower surface of the pressure-sensitive adhesive layer 3 is bonded to the upper surface of the release layer 4. Then, it also includes a transmissive layer 2, the upper surface of the transmissive layer 2 is bonded to the lower surface of the reflective layer 1, the lower surface of the transmissive layer 2 is bonded to the upper surface of the pressure-sensitive adhesive layer 3, and the transmissive layer 2 is provided with fine particles 21 .

[0069] Preferably, the reflective layer 1 includes a highly transparent weather-resistant layer 11 and a microstructure reflective layer 12, the upper surface of the microstructure reflective layer 12 is bonded to the lower surface of the highly transparent weather-resistant layer 11, and the microstructure reflective layer The low...

Embodiment 2

[0087] In the step (b), take the binder, the fine particles 21, the dispersant, the wetting agent, the light stabilizer, the ultraviolet absorber and place all the components in a closed container with a stirring device and a cooling jacket. In the container, after high-speed stirring, all components are dispersed and mixed uniformly to prepare a mixture, and then the mixture is made into a film with a thickness of 70um to form the transmission layer 2 .

[0088] Other implementations are the same as in Example 1.

Embodiment 3

[0090] In the step (b), take the binder, the fine particles 21, the dispersant, the wetting agent, the light stabilizer, the ultraviolet absorber and place all the components in a closed container with a stirring device and a cooling jacket. In the container, after high-speed stirring, all components are dispersed and mixed uniformly to prepare a mixture, and then the mixture is made into a film with a thickness of 40um to form the transmission layer 2 .

[0091] Other implementations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com