A kind of air filter paper containing carbon nanometer material and preparation method thereof

A technology of air filter paper and carbon nanomaterials, applied in filter paper, separation method, filtration and separation, etc., can solve the problems of difficult carbon nanomaterials to use air filtration, large size difference, etc., to achieve easy control of process parameters and solve service life. Short, inexpensive to manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

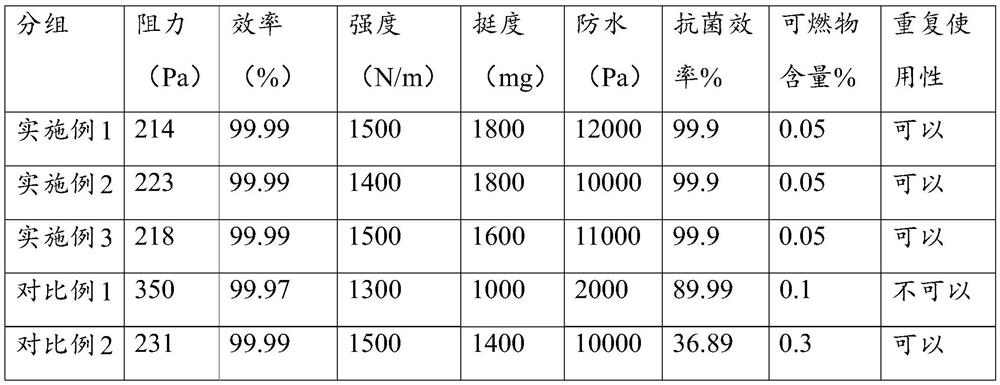

Examples

Embodiment 1

[0027] The air filter paper containing carbon nanomaterials of the present embodiment is made of the following raw material components in parts by weight: 48 parts of glass fibers, 37 parts of carbon nanotubes, 18 parts of silica gel, 12 parts of aluminum chloride, 7 parts of sorbic acid, 13 parts of sodium carboxymethylcellulose and 20 parts of sodium dodecylbenzenesulfonate.

[0028] The preparation method of the above-mentioned air filter paper containing carbon nanomaterials, comprises the following steps:

[0029] S1, weighing each raw material according to the weight ratio;

[0030] S2, adding glass fiber into the beater, adding 2 times of deionized water, beating and dispersing for 30min to make glass fiber dispersion;

[0031] S3. Configure aluminum chloride aqueous solution, the concentration of aluminum chloride aqueous solution is 0.5mol / L, add silica gel into aluminum chloride aqueous solution, put it in an incubator at 50°C for 30 minutes, obtain modified silica ...

Embodiment 2

[0036] The air filter paper containing carbon nanomaterials of the present embodiment is made of the following raw material components in parts by weight: 42 parts of glass fibers, 27 parts of carbon nanotubes, 21 parts of silica gel, 18 parts of aluminum chloride, 8 parts of sorbic acid, 14 parts of sodium carboxymethylcellulose and 22 parts of sodium dodecylbenzenesulfonate.

[0037] The preparation method of the above-mentioned air filter paper containing carbon nanomaterials, comprises the following steps:

[0038] S1, weighing each raw material according to the weight ratio;

[0039] S2, adding glass fibers into the beater, adding 3 times of deionized water, beating and dispersing for 20 minutes, to make a glass fiber dispersion;

[0040] S3, configure aluminum chloride solution, the concentration of aluminum chloride aqueous solution is 1.5mol / L, add silica gel into aluminum chloride solution, place it in an incubator at 65°C for 20 minutes, obtain modified silica gel, ...

Embodiment 3

[0045] The air filter paper containing carbon nanomaterials of the present embodiment is made of the following raw material components in parts by weight: 40 parts of glass fibers, 32 parts of carbon nanofibers, 25 parts of silica gel, 18 parts of aluminum chloride, 7 parts of sorbic acid, 14 parts of acrylic resin and 20 parts of sodium dodecylbenzenesulfonate.

[0046] The preparation method of the above-mentioned air filter paper containing carbon nanomaterials, comprises the following steps:

[0047] S1, weighing each raw material according to the weight ratio;

[0048] S2, adding glass fiber into the beater, adding 2.5 times of deionized water, beating and dispersing for 40min, to make glass fiber dispersion;

[0049] S3. Configure aluminum chloride solution, the concentration of aluminum chloride solution is 0.1mol / L, add silica gel into the aluminum chloride solution, and place it in an incubator at 55°C for 30 minutes to obtain modified silica gel, take out the modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com