Microwave-driven electrodeless ultraviolet sterilizer

A technology of extreme ultraviolet and infinite ultraviolet, applied in chemical instruments and methods, light water/sewage treatment, water/sewage treatment, etc., can solve problems such as exhaustion and short service life of ultraviolet lamps, so as to improve continuity and reduce maintenance time and maintenance costs, and the effect of improving the sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

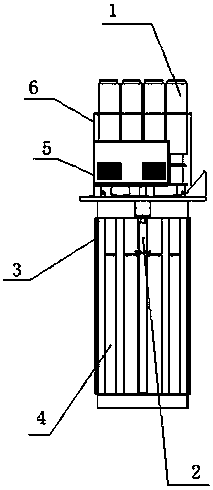

[0020] A microwave electrodeless ultraviolet sterilizer, comprising a bracket 3, a microwave generator 1, a microwave driver and an electrodeless ultraviolet lamp tube 4, wherein a plurality of parallel electrodeless ultraviolet lamp tubes 4 are vertically installed in the support 3; the microwave driver The microwave generator 1 is located above the support 3, and the microwave generator 1 is detachably connected to the upper end of the electrodeless ultraviolet lamp tube 4; the electrodeless ultraviolet lamp tube 4 is a quartz lamp tube, and an electrodeless ultraviolet light source is arranged inside; One side of the support 3 is provided with an air inlet, and the other side is provided with an air outlet; water inlet holes are evenly distributed on the back plate of the support, and a microwave detector 2 is arranged in the middle of the plurality of electrodeless ultraviolet lamp tubes 4 .

Embodiment 2

[0022] A microwave electrodeless ultraviolet sterilizer, comprising a bracket 3, a microwave generator 1, a microwave driver and an electrodeless ultraviolet lamp tube 4, wherein six parallel electrodeless ultraviolet lamp tubes 4 are installed upright in the support 3; the microwave driver The microwave generator 1 is located above the support 3, and the microwave generator 1 is detachably connected to the upper end of the electrodeless ultraviolet lamp tube 4; the electrodeless ultraviolet lamp tube 4 is a quartz lamp tube, and an electrodeless ultraviolet light source is arranged inside; One side of the support 3 is provided with an air inlet, and the other side is provided with an air outlet; the back plate of the support is evenly distributed with water inlets, and the middle of the six electrodeless ultraviolet lamps 4 is provided with a microwave detector 2 .

[0023] The electrodeless ultraviolet lamp tube 4 has a built-in ultraviolet light source with a wavelength of ...

Embodiment 3

[0025] A microwave electrodeless ultraviolet sterilizer, comprising a bracket 3, a microwave generator 1, a microwave driver and an electrodeless ultraviolet lamp tube 4, four parallel electrodeless ultraviolet lamp tubes 4 are installed upright in the support 3; the microwave driver The microwave generator 1 is located above the support 3, and the microwave generator 1 is detachably connected to the upper end of the electrodeless ultraviolet lamp tube 4; the electrodeless ultraviolet lamp tube 4 is a quartz lamp tube, and an electrodeless ultraviolet light source is arranged inside; One side of the support 3 is provided with an air inlet, and the other side is provided with an air outlet; the back plate of the support is evenly distributed with water inlets, and the middle of the four electrodeless ultraviolet lamps 4 is provided with a microwave detector 2 .

[0026] The electrodeless ultraviolet lamp tube 4 has a built-in ultraviolet light source with a wavelength of 255 na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com