Flexible lamp strip

A flexible light bar, flexible technology, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems of cumbersome production process, easy to break, affecting the service life of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

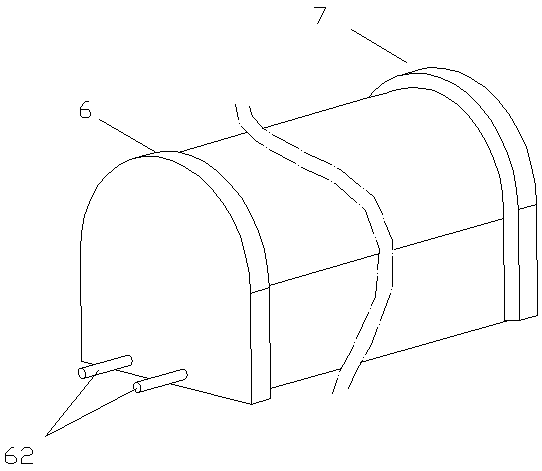

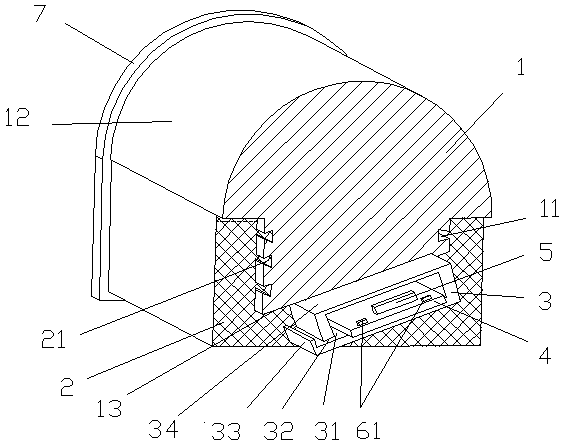

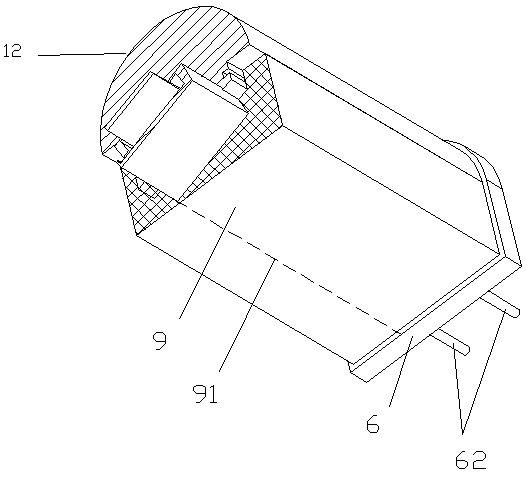

[0017] refer to Figure 1-4 2. The present invention includes a flexible light-transmitting plastic lamp body core wire 3, the lamp body core wire is a light-transmitting plastic strip, and a longitudinal through hole 31 is arranged in the core wire along the longitudinal direction, and the cross-section of the through hole is rectangular. It can be set in a convex shape, and there is a slit-shaped opening 32 along the longitudinal direction between the bottom side of the through hole and the surface of the core wire. The end is provided with a rib 33 that protrudes toward the top direction, and the rib is arranged along the longitudinal direction. The core wire of the lamp body is formed by a soft transparent PVC material through a plastic extruder. The PVC can also be a colored transparent plastic material. Flexible PCB boards 4 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com