Rust-proof treatment method for bolt

A processing method and bolt technology, applied in the mechanical field, can solve the problems of poor processing effect and achieve reliable processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

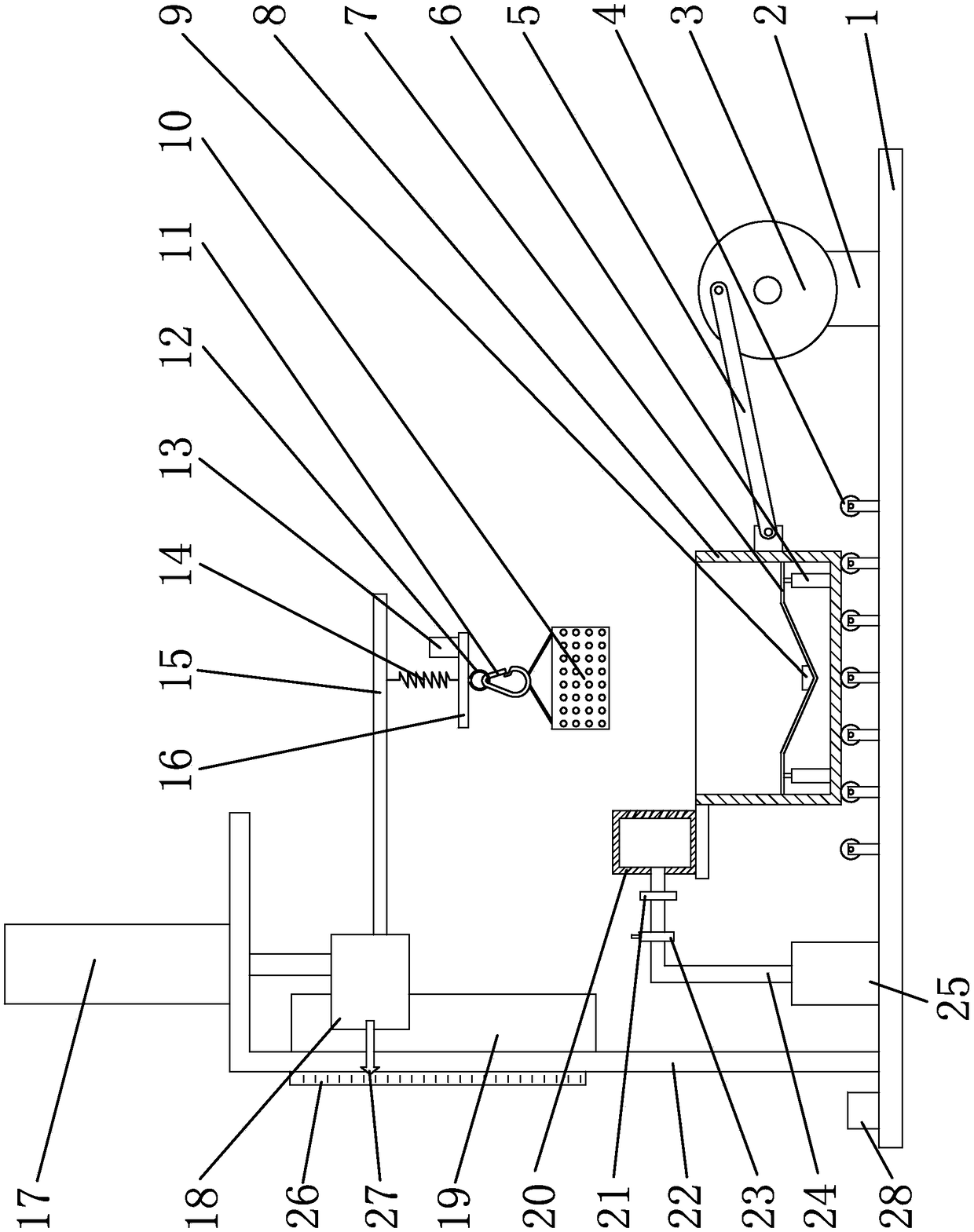

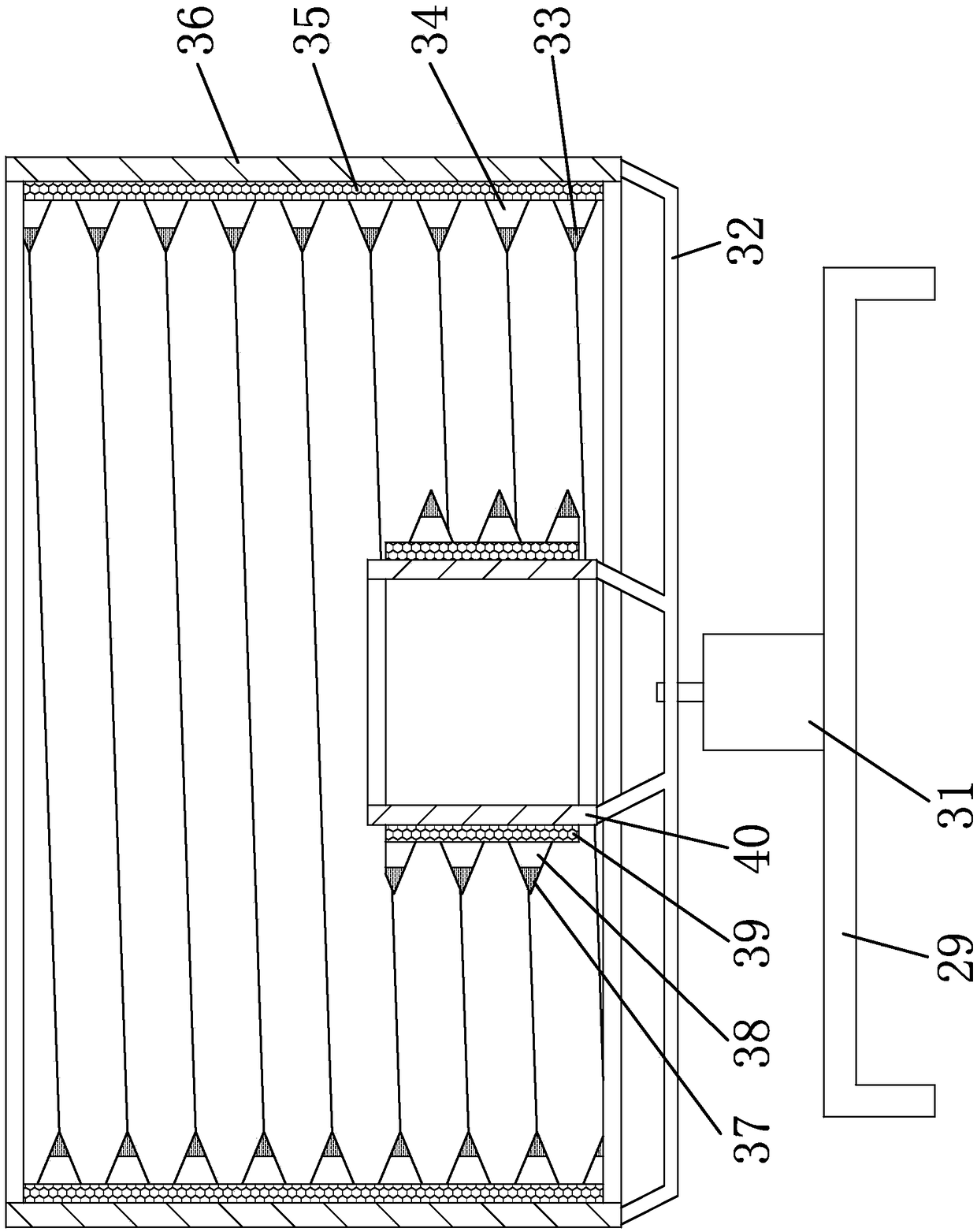

[0038] Such as figure 1As shown, the anti-rust treatment method for bolts includes the following steps: a. Cleaning: Clean the bolts with a washing machine to remove iron filings and sundries. The cleaning temperature is 60-80°C and the cleaning time is 10-16 minutes; b , Drying: Put the cleaned bolts into an oven for drying, the drying temperature is 100-110°C, and the drying time is 3-8min; c, Soaking: Put the dried bolts in anti-rust oil Soaking, soaking time is 1-3min; d, packing: the bolt after soaking is packed with carton; The temperature is 66°C, and the cleaning time is 12 minutes; b. Drying: put the cleaned bolts into an oven for drying, the drying temperature is 108°C, and the drying time is 4 minutes; c. Soaki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com