Improved production method of nanometer lithium iron phosphate cathode material

A lithium iron phosphate, cathode material technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve problems such as inability to guarantee product quality, poor product quality, etc., to avoid clogging and ensure consistency sex, ensure the effect of normal progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

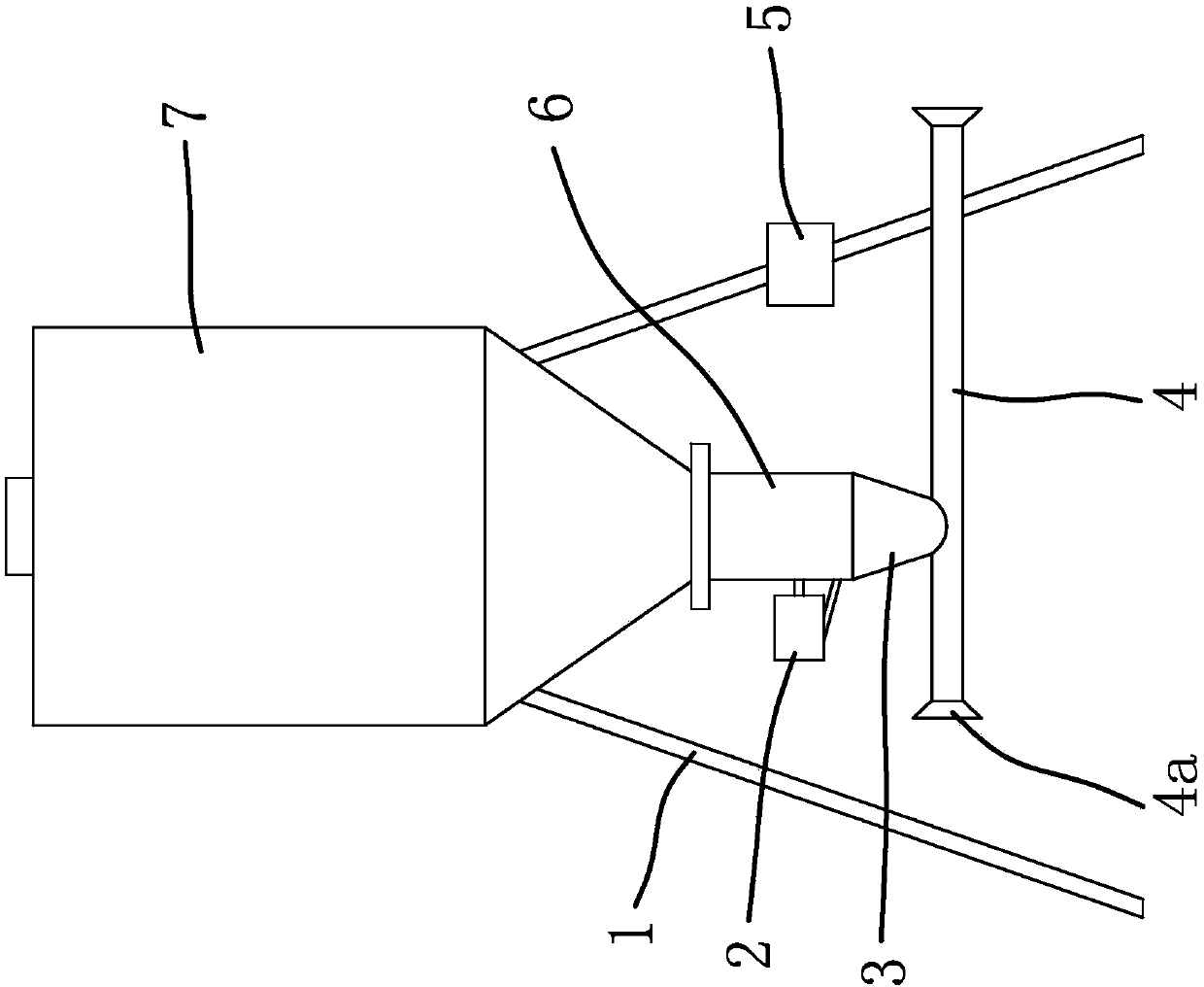

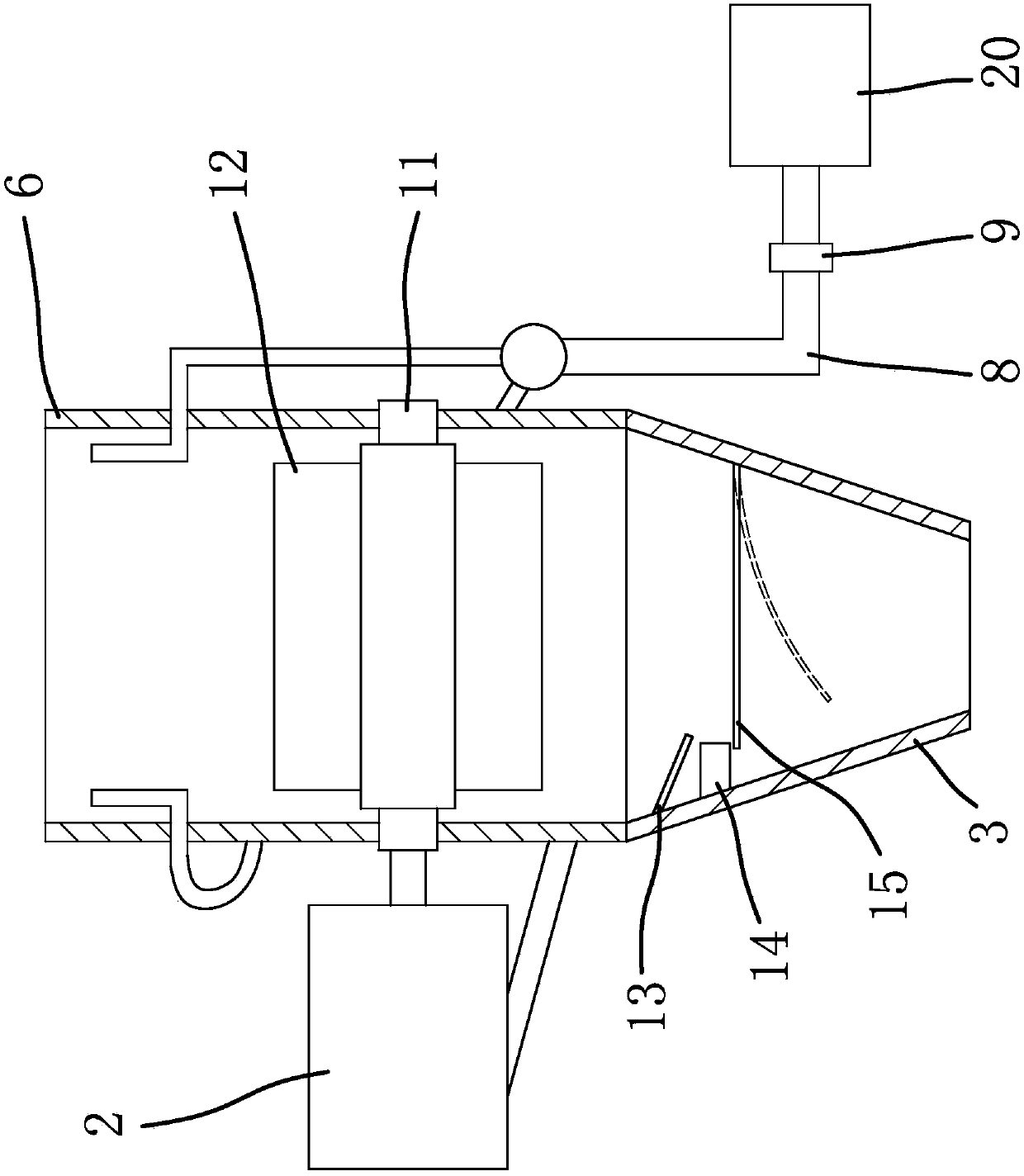

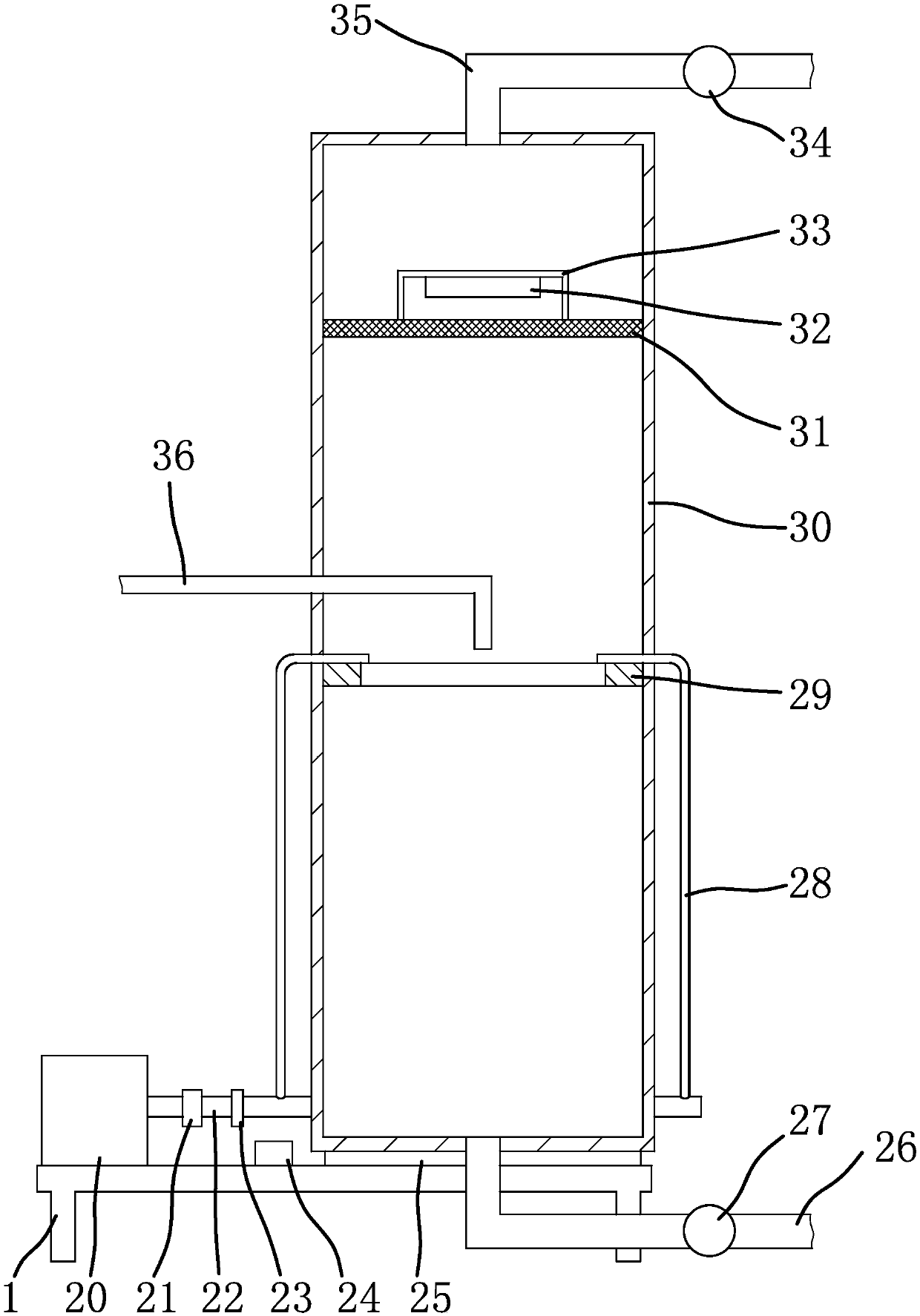

[0055] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0056] The production process of the improved nano-lithium iron phosphate cathode material comprises the following process steps:

[0057] a. Mix lithium source compound, trivalent iron source compound and phosphorus source compound with water according to the stoichiometric ratio, then add doped metal ion oxide and primary carbon source, and mix evenly; the formed slurry is subjected to a high-energy ultrafine grinding treatment 2-3h, the D50 of the obtained slurry is less than 0.2 μm, spray dry to obtain a dry powder, and sieve; in this embodiment, the formed slurry is subjected to a high-energy ultrafine grinding treatment for 2.5h; the lithium source compound is lithium carbonate; Ferric iron source compound is Fe 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com