Improved production method of nanometer light guide particles

A light-guiding particle and production method technology, applied in chemical instruments and methods, filters, grids, etc., can solve the problems of low production efficiency and complicated steps of the preparation method, and achieve good work stability, continuous and uninterrupted production, Avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

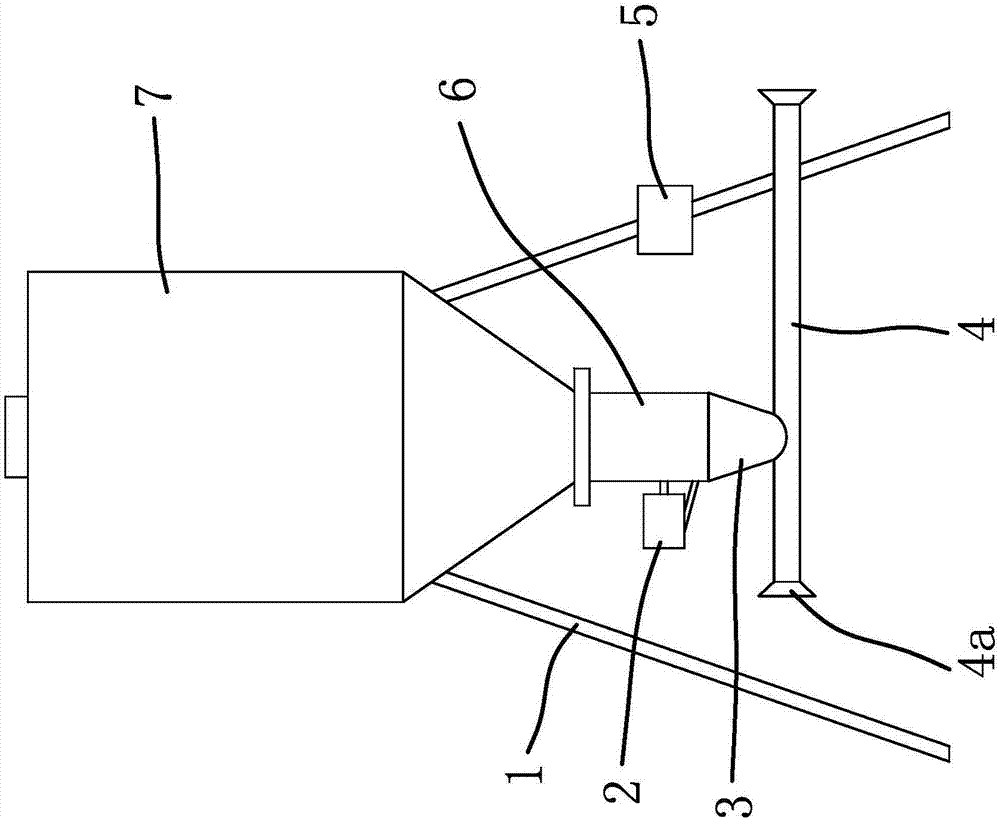

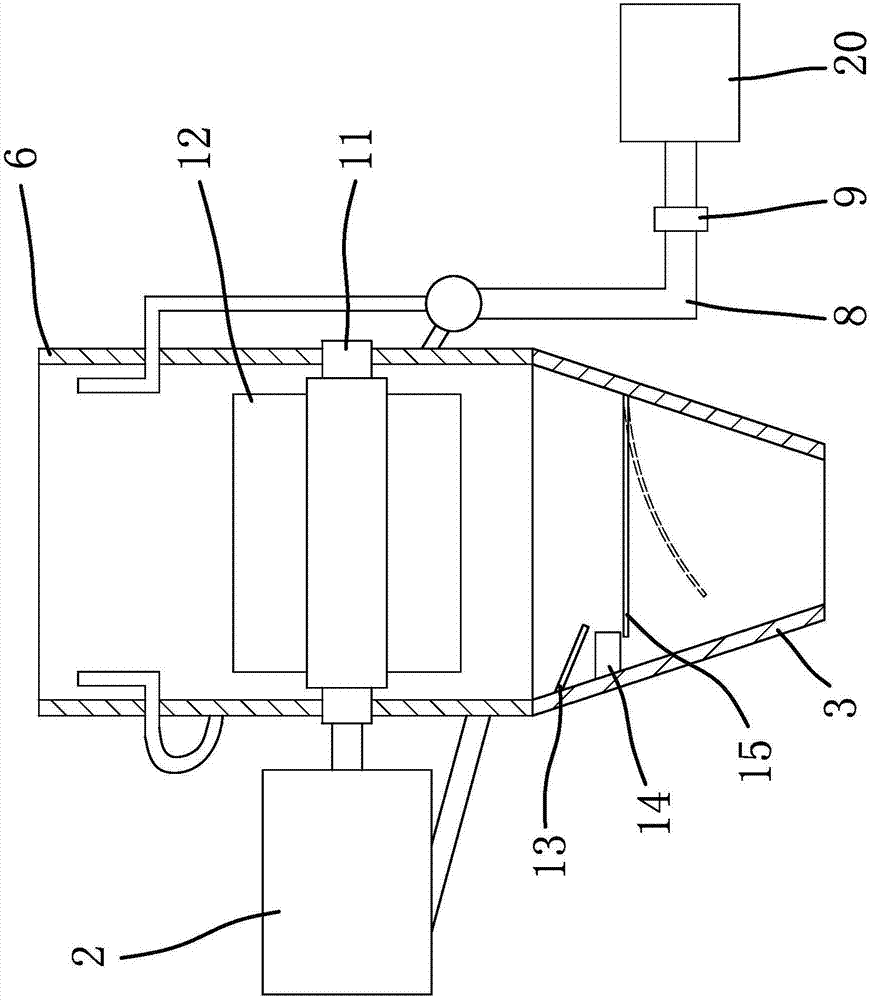

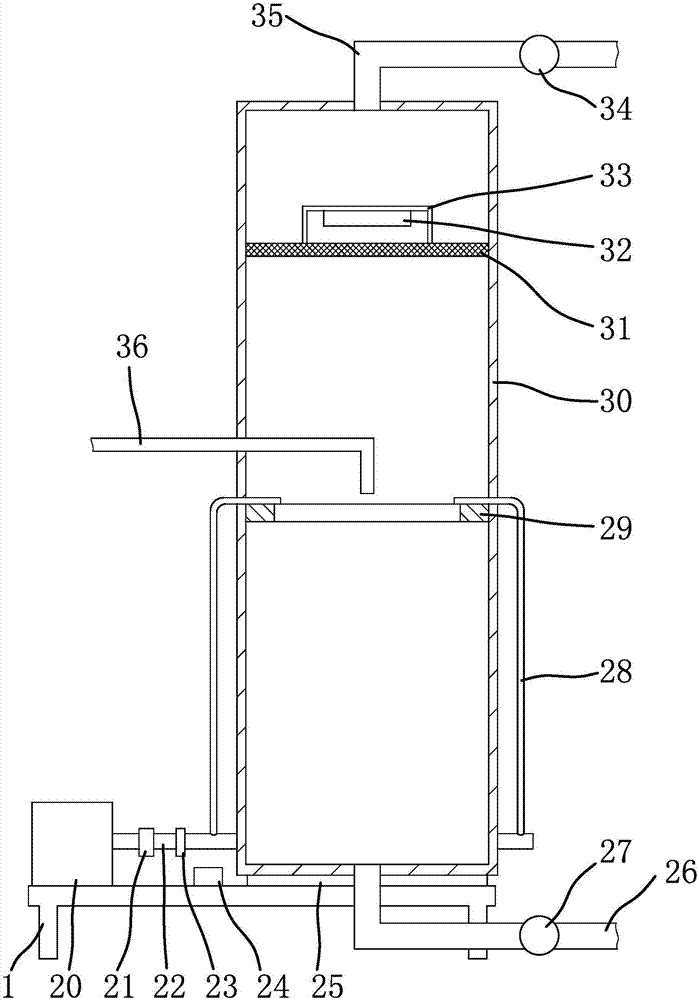

[0055] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0056] The production method of the improved nano light-guiding particles, the method comprises the following steps as follows:

[0057] a. Under the action of ultrasonic stirring, weigh 6-12% absolute ethanol, 3-8% terpineol, 4-7% stearic acid, 6-12% coupling agent, 3-5% by mass percentage % fluorescent powder and 50-76% nano light guide powder for surface treatment for 10-24min, in this embodiment, weigh 10% absolute ethanol, 5% terpineol, 6% stearic acid, 8% coupling agent , 4% fluorescent powder and 58% nano-light guide powder for surface treatment for 16 minutes; the nano-light guide powder is titanium dioxide, and the coupling agent is sodium polyacrylate;

[0058] b. Add 9% anti-scratch additive to the nano-light g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com