A fish fertilized egg debonding and cleaning system and its technological process

A cleaning system and fertilized egg technology, applied in the field of aquaculture, can solve problems such as difficult to achieve standardized operations, high labor intensity, and existence of dead ends, and achieve controllable cleaning intensity and time, reduce labor intensity, and increase production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific examples.

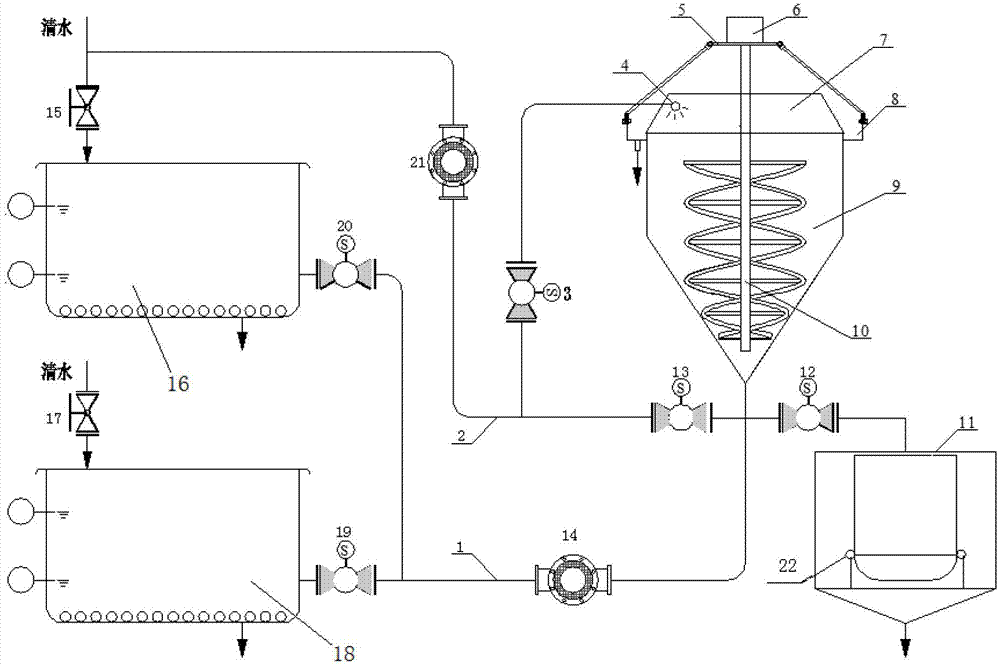

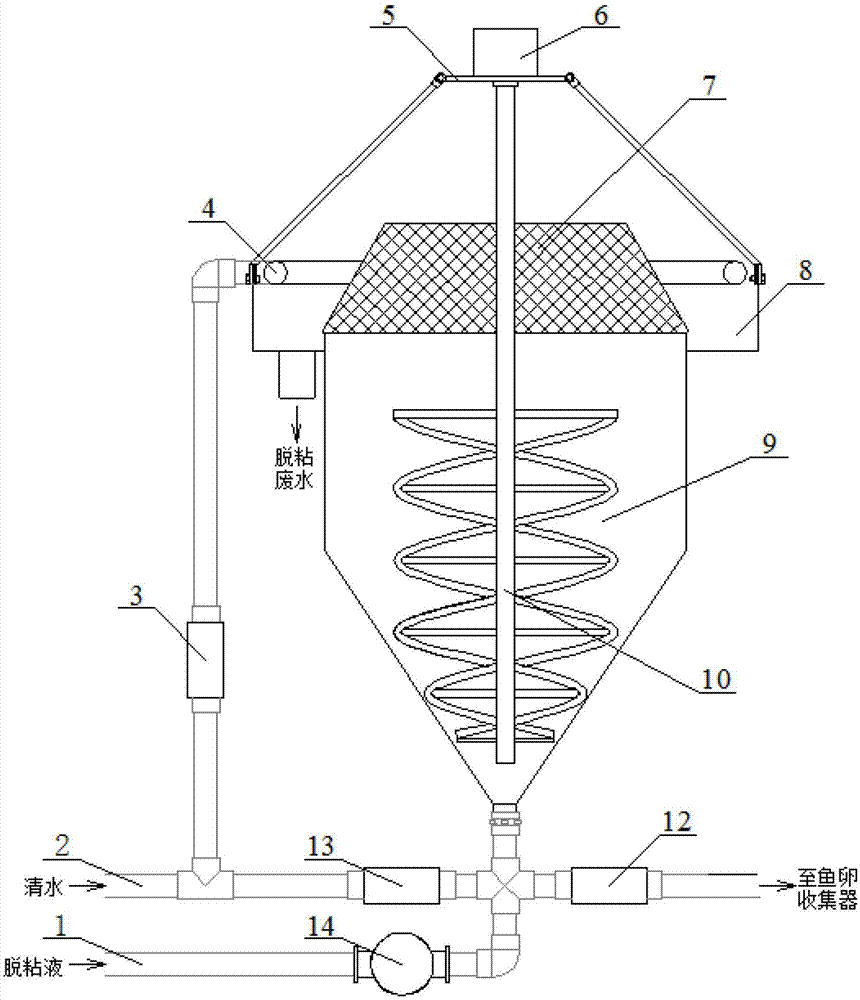

[0037] see Figure 1-2 , a system for debonding and cleaning fish fertilized eggs, comprising a debonding solution deployment and supply device, debonding cleaning equipment, and a fish egg collector 11; shape, the center is provided with a screw ribbon agitator, and the screw ribbon agitator is driven by a motor 6 fixed above it, and the lower end of the debonding cleaning cylinder 9 is open and connected to the fish roe collector 11 and the clean water inlet pipe respectively through a four-way connecting pipe. 2. The debonding liquid inlet pipe 1 is connected, and the upper part of the outer wall of the debonding cleaning cylinder 9 is also fixed with an overflow ring groove 8, and the lower part of the overflow ring groove 8 is provided with a debonding waste water port, and the debonding waste water is discharged from the debonding cleaning cylinder 9 overflows, enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com