Method and device for medium boiling components of separating complex systems and returning low boiling components to original systems

A system and complex technology, applied in the field of separation and purification of chemical chemicals, can solve the problems of difficult separation and separation of intermediate components, achieve better separation effect, avoid large equipment, and achieve continuous and uninterrupted production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

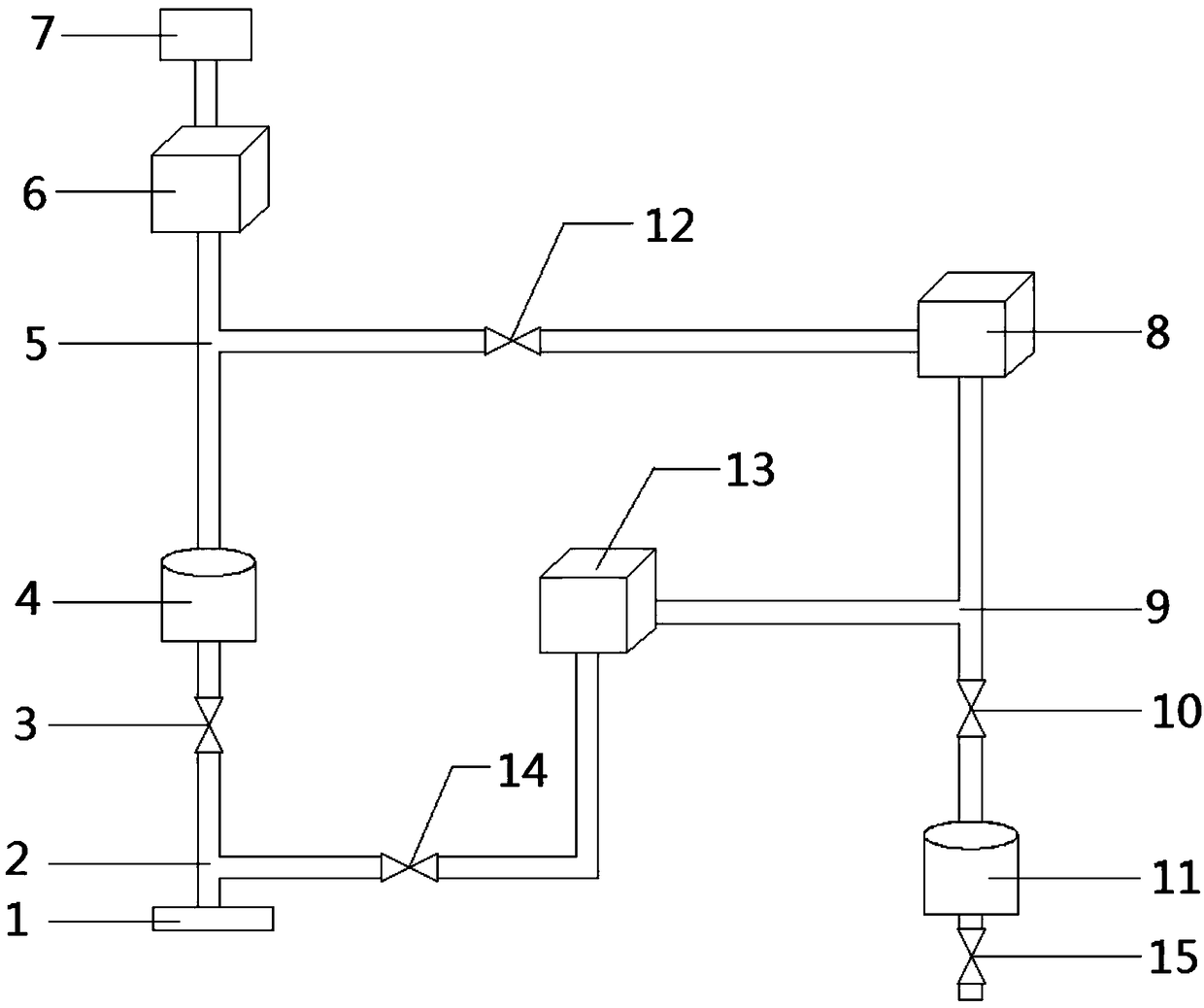

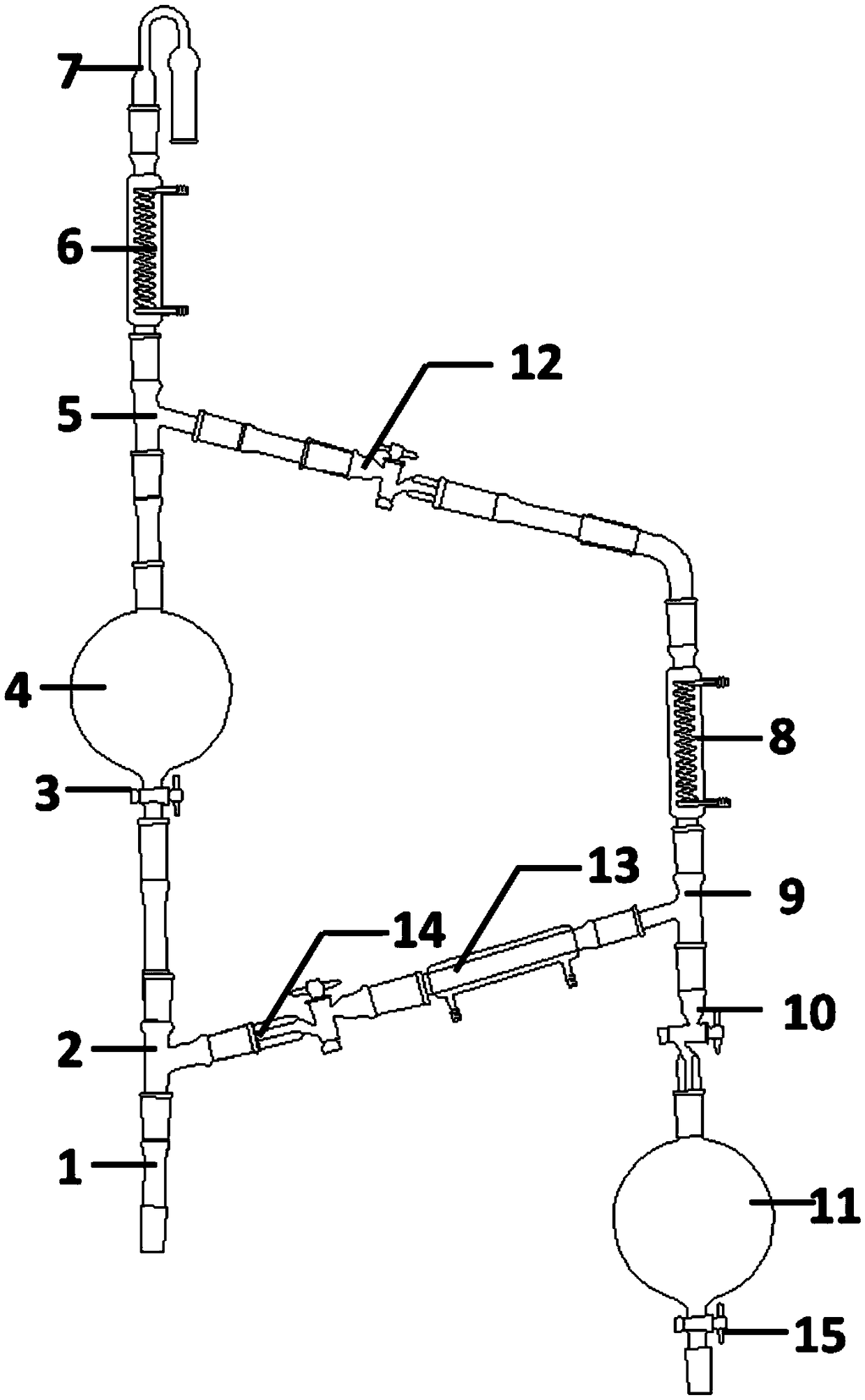

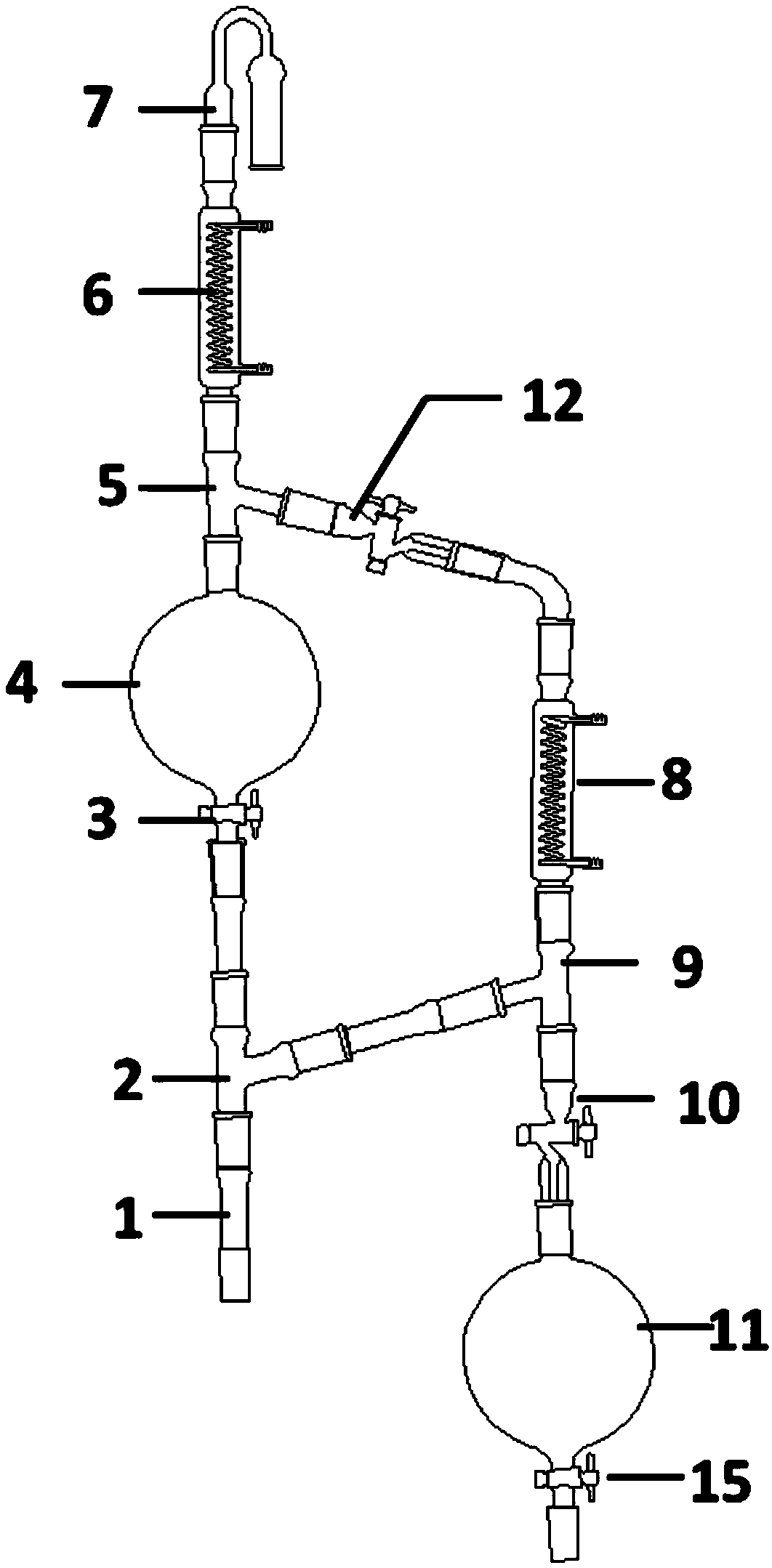

[0052] like figure 2 As shown, a device for separating the middle boiling components of a complex system and returning the low boiling components to the original system, including a reactor interface 1, a first liquid collection device 4, a first temperature control system 6, a tail gas collection device 7, The second temperature control system 8 , the second liquid collection device 11 and the third temperature control system 13 . Wherein, the first liquid collection device 4 and the second liquid collection device 11 are both spherical containers; the first temperature control system 6 and the second temperature control system 8 are serpentine condensers, and the temperature control method is the temperature control of circulating water at a specific temperature The third temperature control system 13 is a straight condenser, and the temperature control mode is temperature control of circulating water at a specific temperature; the tail gas collection device 7 is a spherica...

Embodiment 2

[0057] The method of adopting the device described in embodiment 1 to separate the middle boiling components of the complex system and making the low boiling components return to the original system comprises steps as follows:

[0058] (1) Close all valves in the device first, and connect the reactor interface 1 to the reactor before the system starts to react. After the connection is completed, open the first valve 3, so that the gas in the system passes through the first valve 3 and the first liquid is collected in sequence. The device 4, the first temperature control system 6, the exhaust gas collection device 7 and communicated with the outside atmosphere;

[0059] (2) After the reaction starts and reaches stability, adjust the first temperature control system 6 to make the low-boiling components reflux, avoiding the low-boiling components being collected by the tail gas collection device 7 and causing losses, so that the system reaches stability; The boiling component is ...

Embodiment 3

[0066] A device for separating the middle boiling components of a complex system and returning the low boiling components to the original system, as described in Example 1, the difference is that the first temperature control system 6 and the second temperature control system 8 are both spherical condensation device, the temperature control method is temperature control of circulating water at a specific temperature; the exhaust gas collection device 7 is an exhaust gas absorption pipe with a liquid absorption pool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com