A production line for processing solar cells

A solar cell and production line technology, applied in sustainable manufacturing/processing, circuits, electrical components, etc., can solve the problems of cumbersome production and inability to realize continuous and uninterrupted production, achieve reliable cleaning, reduce damage rate, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

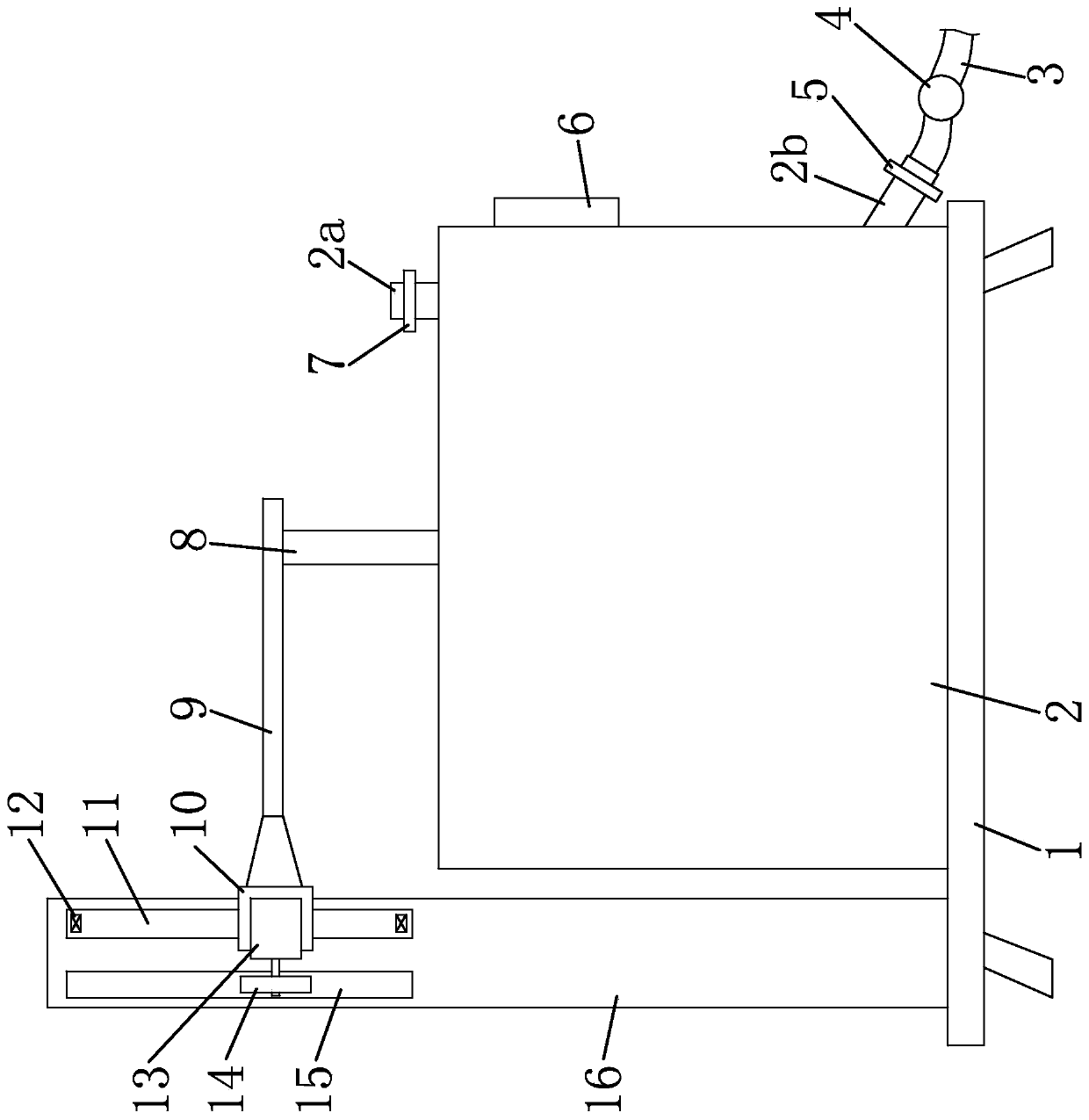

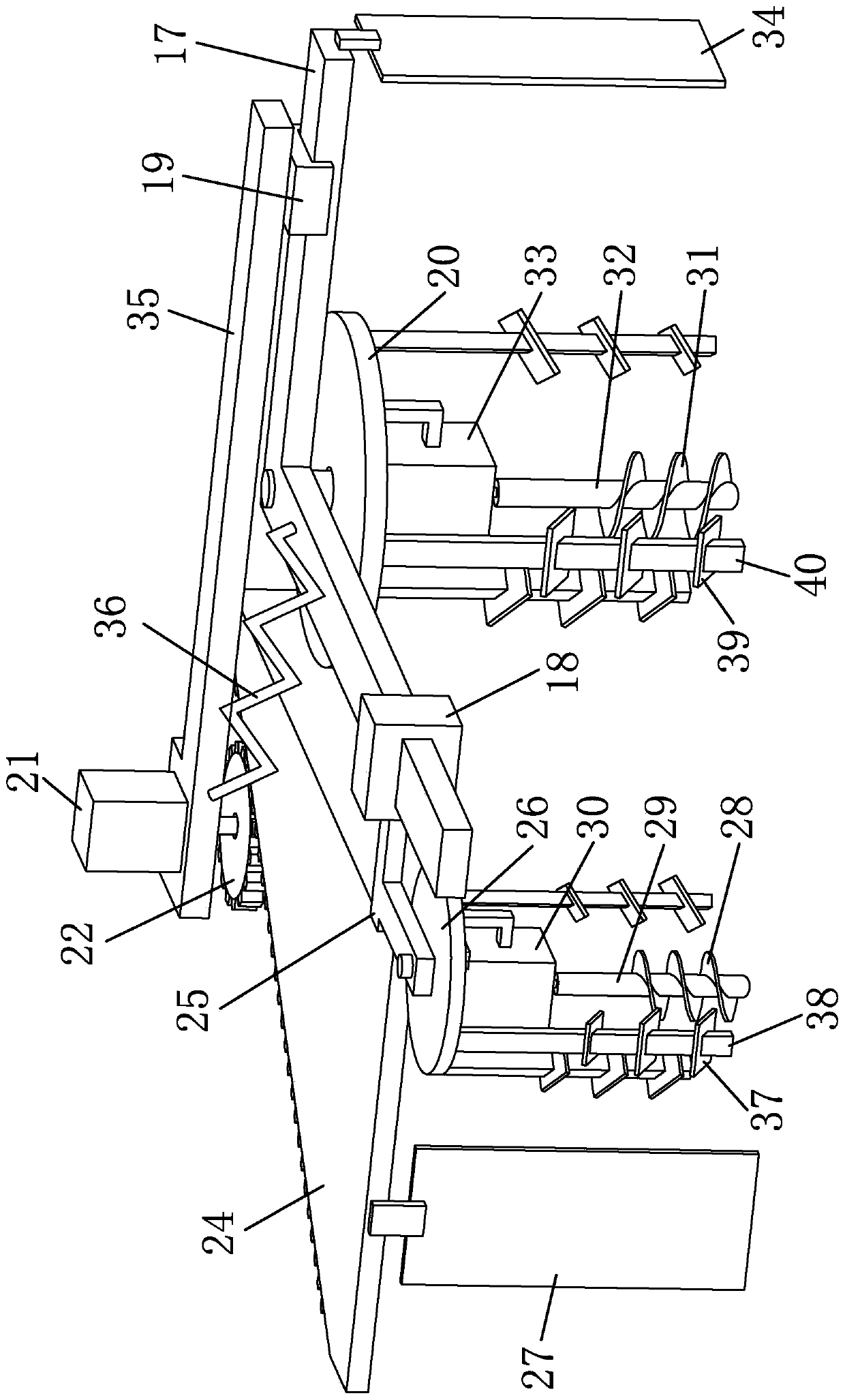

[0055] Such as Figure 1-Figure 7 As shown, the processing production line of the solar cells includes a base, and inspection equipment, texturing equipment, diffusion equipment, etching equipment, phospho-silicate glass removal equipment, coating equipment, screen printing equipment and sintering equipment are sequentially arranged on the base. Equipment; In this embodiment, the inspection equipment, texturing equipment, diffusion equipment and sintering equipment adopt the existing structure.

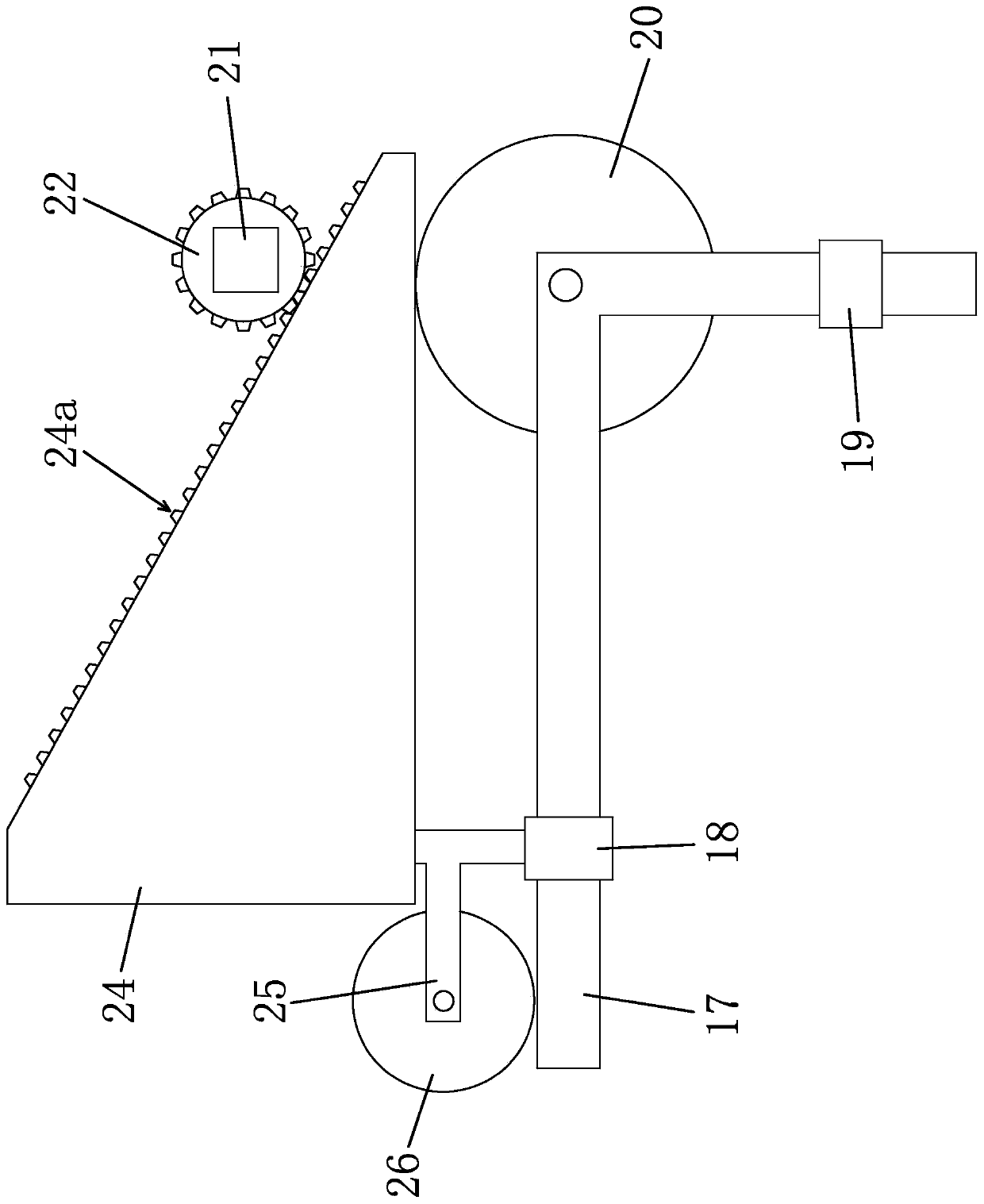

[0056] The screen printing equipment includes a first frame 1, the first frame 1 is fixed on the base, and a conveying mechanism, a plurality of printing mechanisms, a slurry stirring mechanism and a sheet turning mechanism are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com