A kind of fully automatic production device and production method of composite material grid

A technology for composite materials and production equipment, which is applied in the field of fully automatic production equipment for composite material grids, can solve the problems that automatic production equipment cannot be matched with mold equipment, automatic production equipment cannot be well applied, and mold equipment is expensive. Computer networked real-time monitoring and remote fault diagnosis, improving versatility and utilization, improving the effect of resin utilization and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

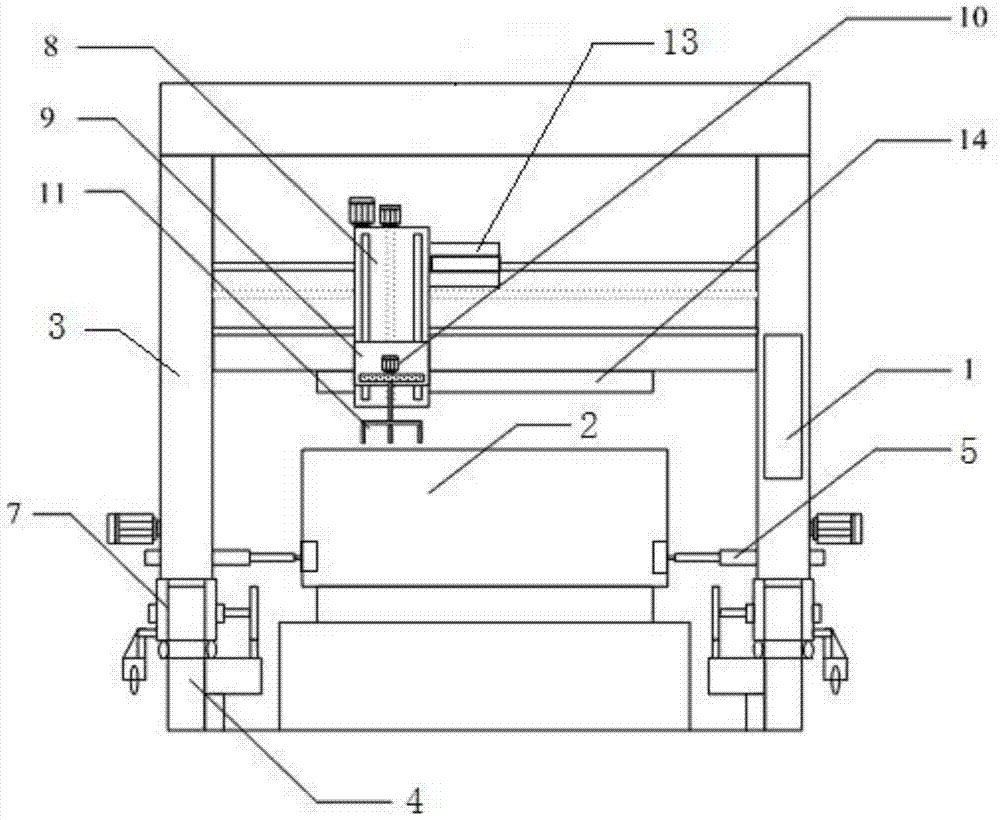

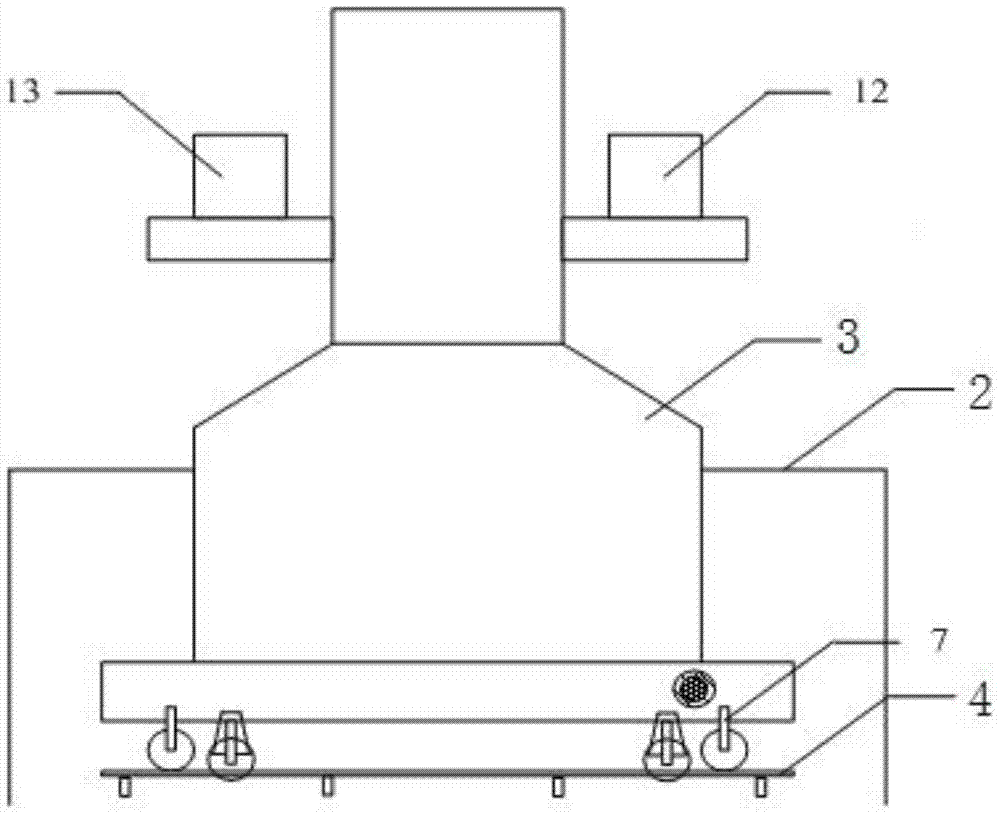

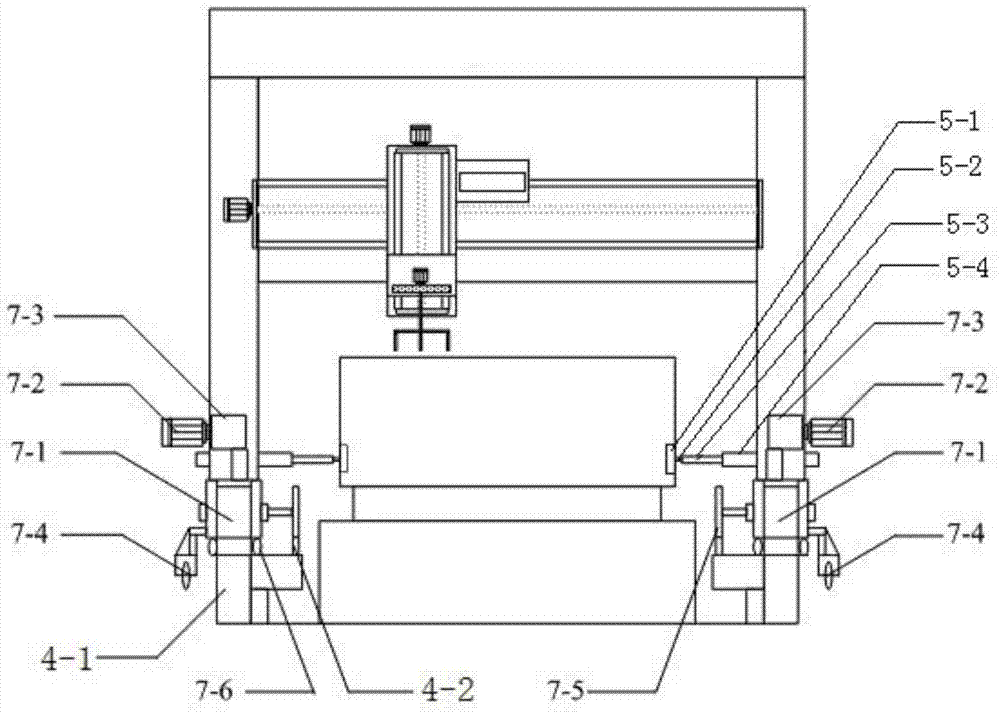

[0036] The present invention will be further explained below in conjunction with the accompanying drawings.

[0037] like figure 1 and 2 As shown, the composite grid automatic production device of the present invention includes a mold table 2, a gantry frame 3, a track mechanism 4, a guide mechanism 5, a walking mechanism 7, a slide mechanism 8, an elevating mechanism 9, and a rotary mechanism 10 , Laying working head 11, wire feeding mechanism 12, glue injection mechanism 13, compacting mechanism 14 and computer control system 1. Rail mechanisms 4 are laid on both sides of the mold platform 2, and the gantry-shaped vehicle frame 3 spans over the mold platform 2. The bottom of the gantry-shaped vehicle frame 3 is provided with a traveling mechanism 7 and a guiding mechanism 5, and the gantry is driven by the traveling mechanism 7. The type vehicle frame 3 moves along the track mechanism 4, and the guide mechanism 5 ensures that the gantry type vehicle frame 3 will not shake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com