Round pipe welding clamping device

A technology for welding clamps and round pipes, which is applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., and can solve problems affecting the welding quality of the radial surface of the round pipe, fixing the round pipe, and affecting the welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

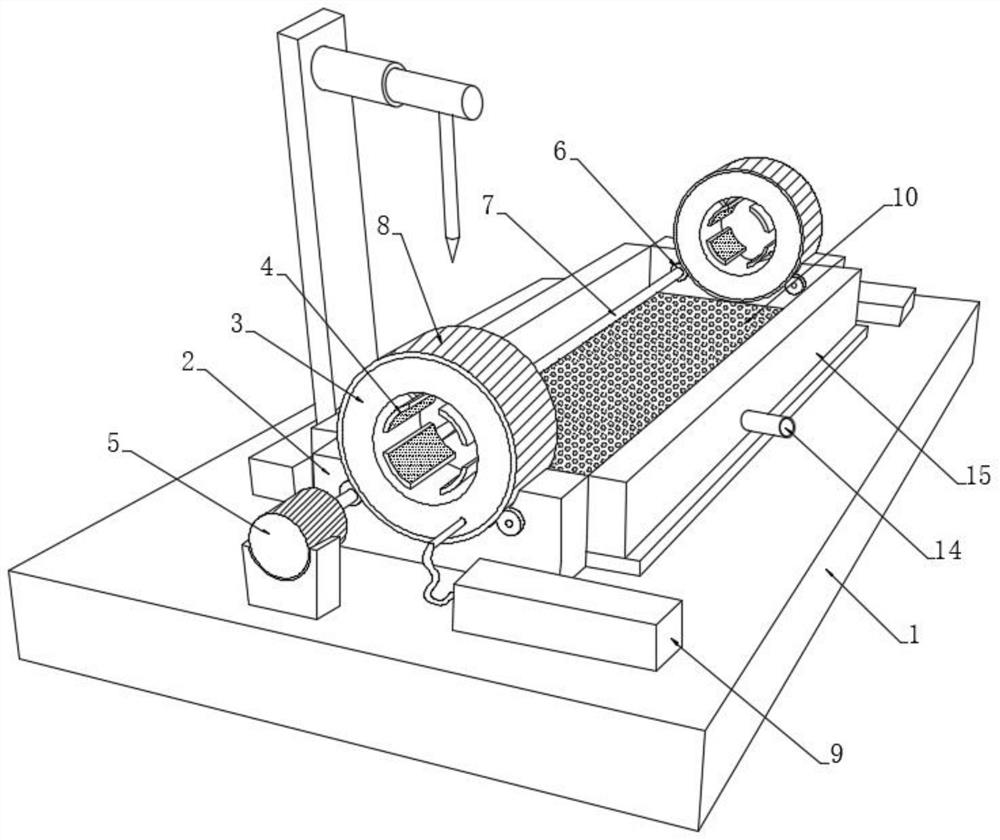

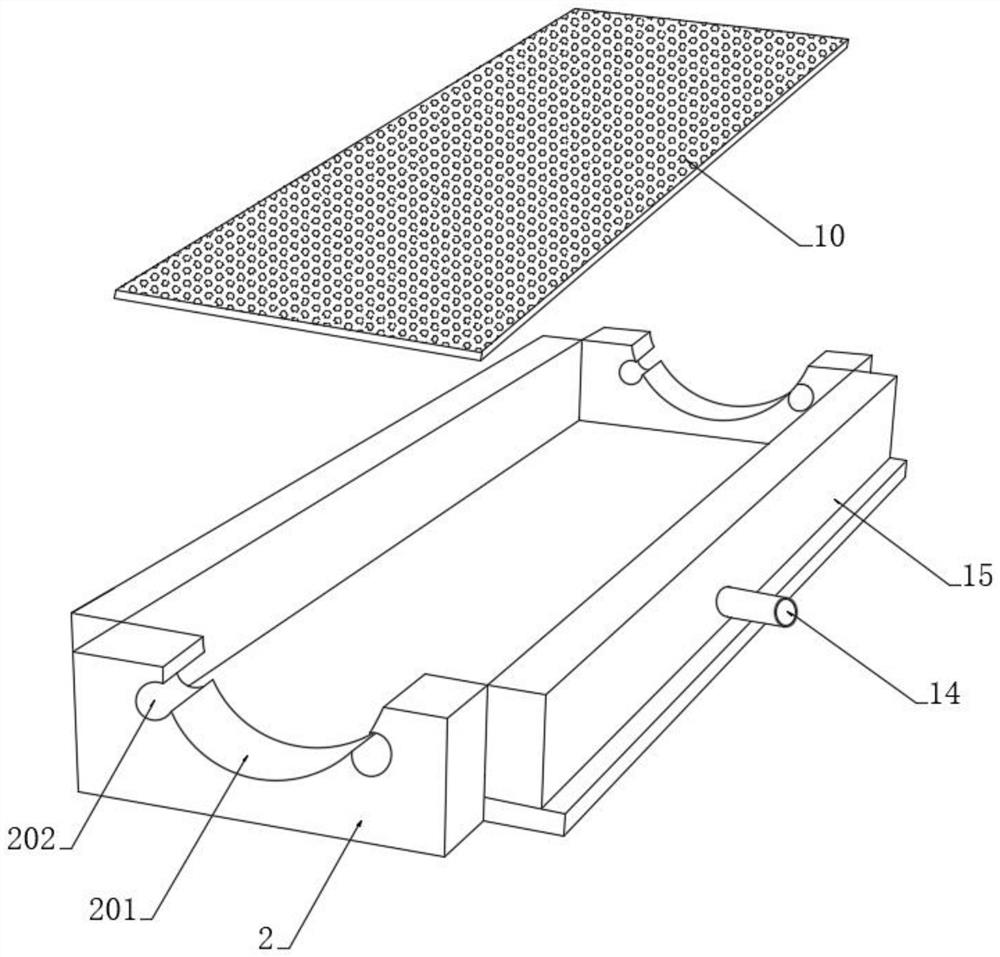

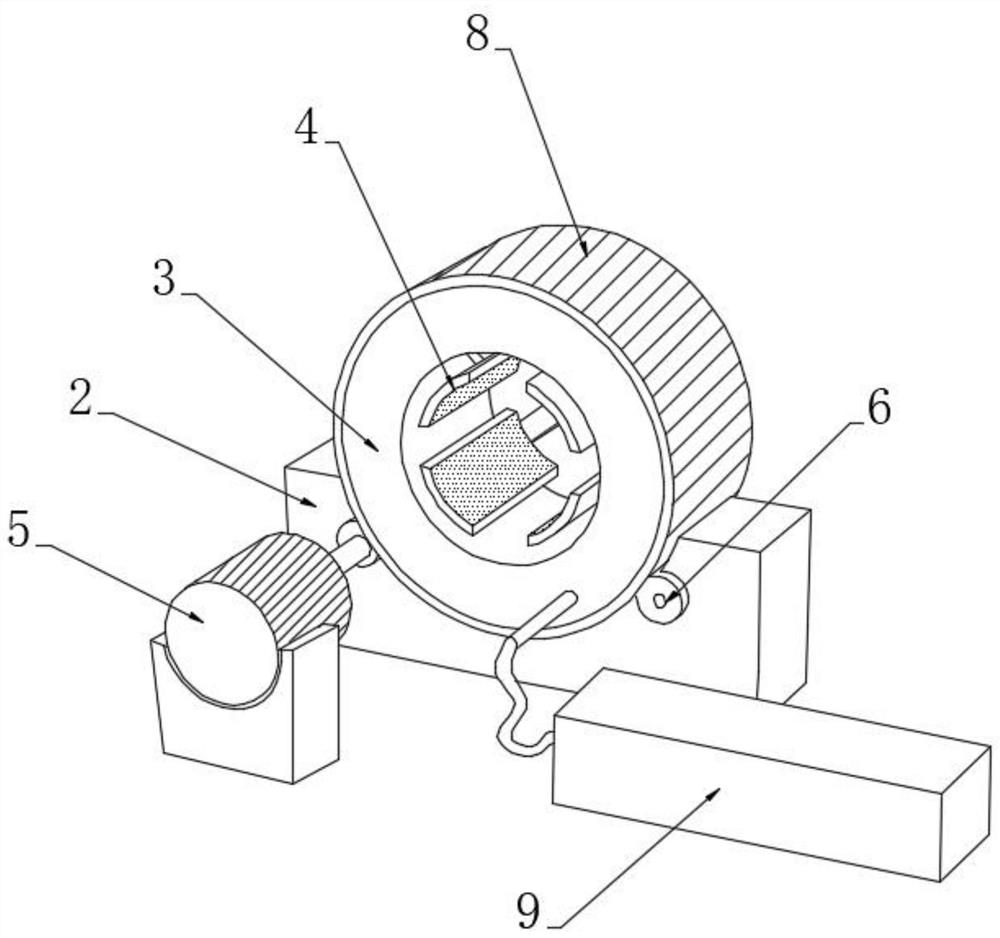

[0039] see Figure 1-3 , a round pipe welding and clamping device, including a console 1 and a rotating seat 2 fixedly installed on the front and rear ends of the console 1, an electric slide rail is provided on the upper end side of the console 1, and an electric slide rail is installed on the electric slide rail The welding machine at the outer side of a pair of rotating bases 2 uses a welding machine to carry out spot welding. This is the prior art, and the process will not be repeated here. A pair of rotating bases 2 is provided with a rotating chamber 201, and the two rotating chambers 201 The hollow annular jacket 3 is connected with both rotations, the rotating motor 5 is fixedly installed on one side of the upper end of the console 1, and the two rotating seats 2 are equipped with a transmission mechanism meshed with the hollow annular jacket 3. The two transmission mechanisms They are connected by a linkage shaft 7, and the driving end of the rotating motor 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com