Ingot-shaped wonton forming device

A molding device and wonton technology, which is applied in the fields of baking, dough processing, food science, etc., can solve problems such as automatic production of ingot wontons, and achieve the effects of improving production efficiency, low failure rate, and consistent size and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

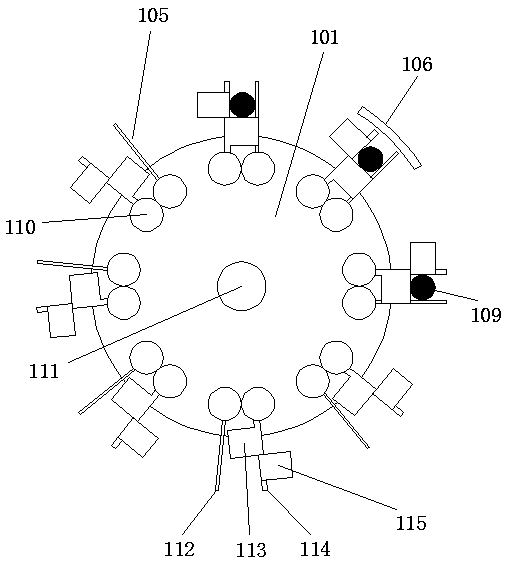

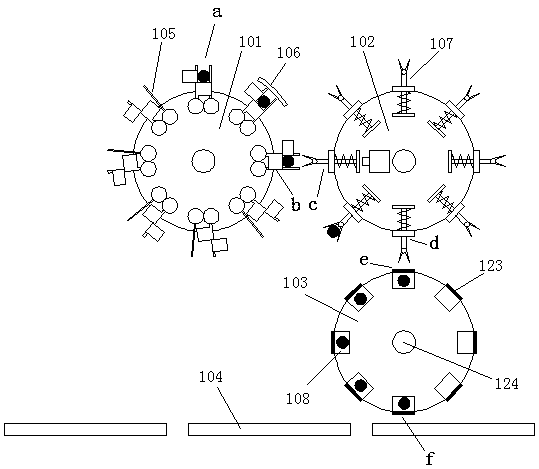

[0031] As a preferred embodiment of the present invention, this embodiment discloses an ingot wonton forming device, which includes:

[0032] An ingot wonton forming device, comprising a forming mold that can move along a fixed trajectory, a stopper is arranged directly above the movement trajectory of the forming mold, and the distance between the stopper and the movement trajectory of the forming mold is greater than the distance between the apex of the forming mold and the movement trajectory distance.

[0033] The molding die includes a bottom plate and a splint mechanism that can be clamped or opened. The splint mechanism includes a splint one and a splint two. The splint one and the splint two are respectively arranged on both sides of the bottom plate; Board, the folding board can rotate four times along the rotating shaft.

[0034] The molding die is arranged on the side wall of the roller 1 that can rotate along the shaft 1 .

[0035] A gear set is arranged on the s...

Embodiment 2

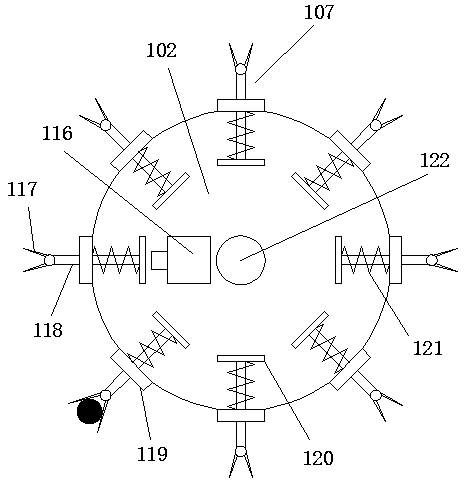

[0039] As a preferred embodiment of the present invention, this embodiment discloses an ingot wonton forming device, which includes:

[0040] An ingot wonton forming device, comprising a forming mold that can move along a fixed trajectory, a stopper is arranged directly above the movement trajectory of the forming mold, and the distance between the stopper and the movement trajectory of the forming mold is greater than the distance between the apex of the forming mold and the movement trajectory distance.

Embodiment 3

[0042] As a preferred embodiment of the present invention, this embodiment discloses an ingot wonton forming device. This embodiment is basically the same as Embodiment 2, except that:

[0043] The molding die includes a base plate and a splint mechanism that can be clamped or opened. The splint mechanism includes a splint 1 and a splint 2. The splint 1 and the splint 2 are respectively arranged on both sides of the base plate; Board, the folding board can rotate four times along the rotating shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com