Steel pipe derusting and paint spraying device for building

A technology for construction and steel pipes, applied in spraying devices, grinding drive devices, manufacturing tools, etc., can solve the problems of low efficiency and heavy labor, and achieve the effect of fast and simple operation, less trouble, and easy handling of steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

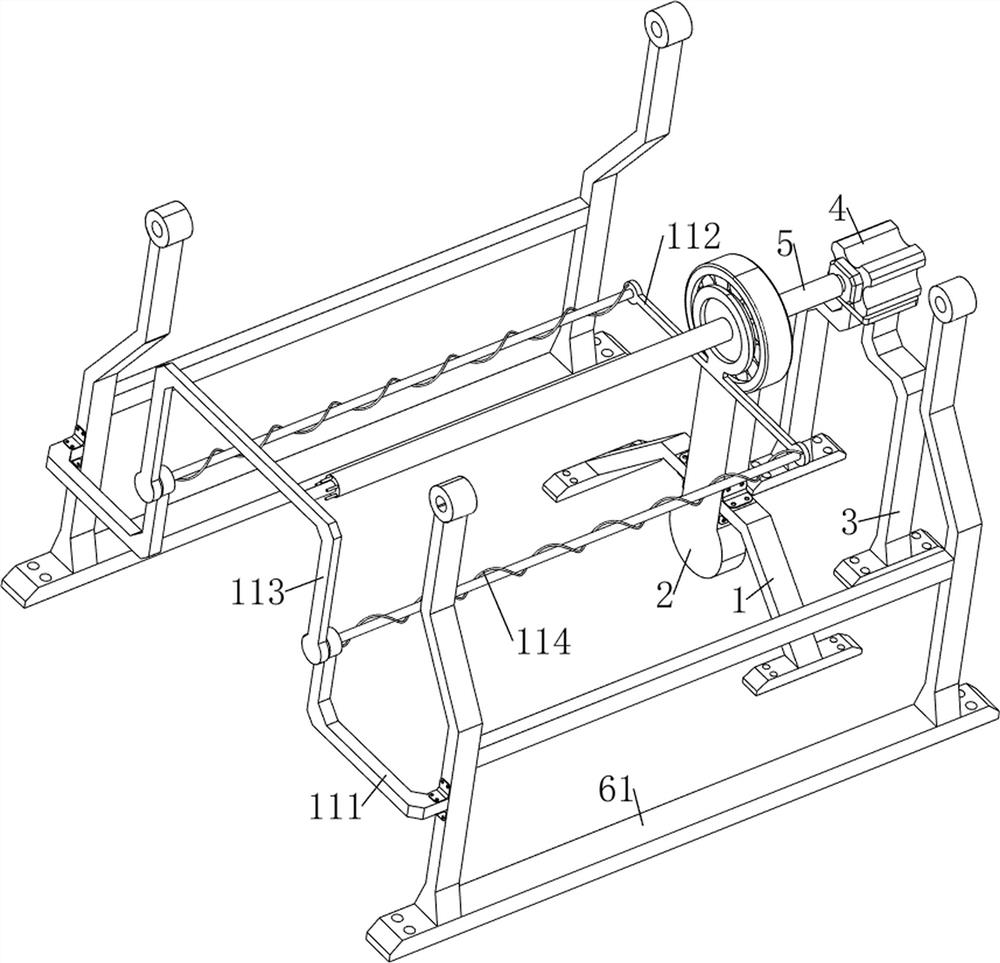

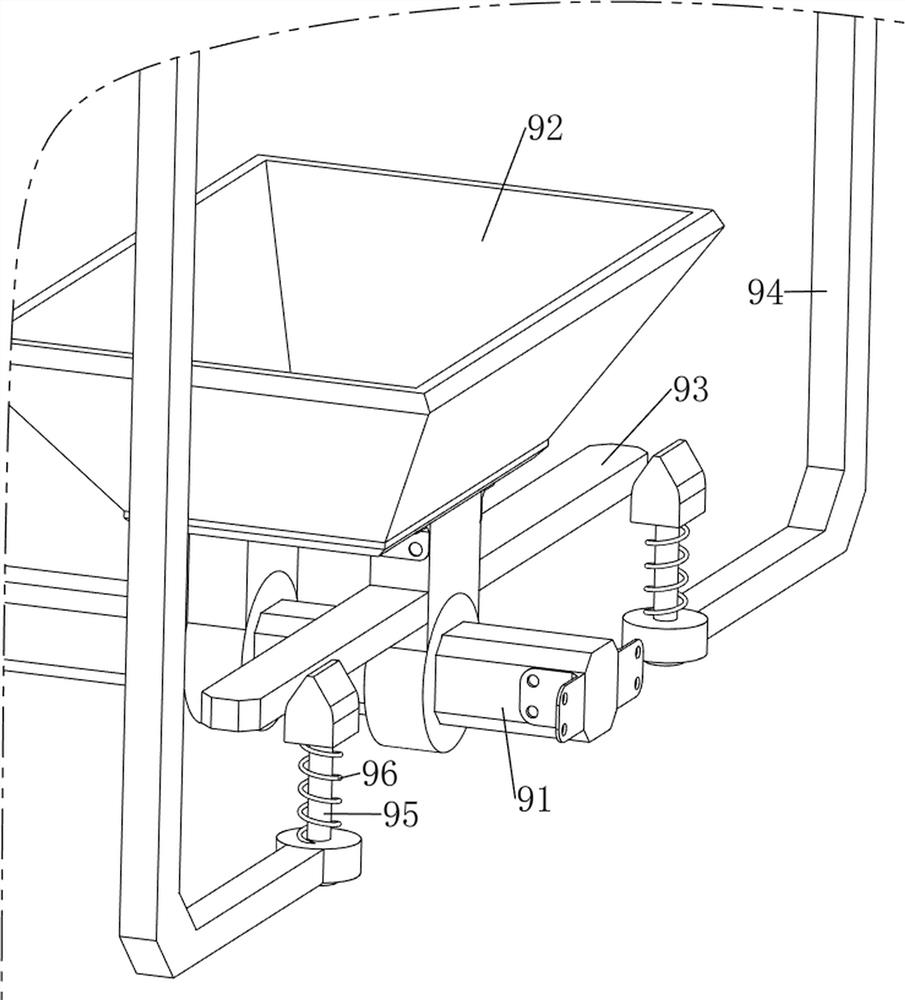

[0037] A steel pipe derusting paint spraying device for construction, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 14 and Figure 15 As shown, it includes a support frame 1, a first connecting rod 2, a first fixed frame 3, a motor 4, a rotating rod 5, a derusting mechanism 11, a moving mechanism 6 and a spraying mechanism 7, and the top of the first fixed frame 3 is provided with a motor 4. The output shaft of the motor 4 is provided with a rotating rod 5 for covering the steel pipe. The support frame 1 is placed symmetrically on the left side of the first fixed frame 3, and the first connecting rod 2 is connected between the two support frames 1. , the rotating rod 5 is connected to the first connecting rod 2 in a rotational manner, and a moving mechanism 6 is placed on the outside of the two support frames 1. The moving mechanism 6 cooperates with the rotating rod 5, and the moving mechanism 6 is provided with a ste...

Embodiment 2

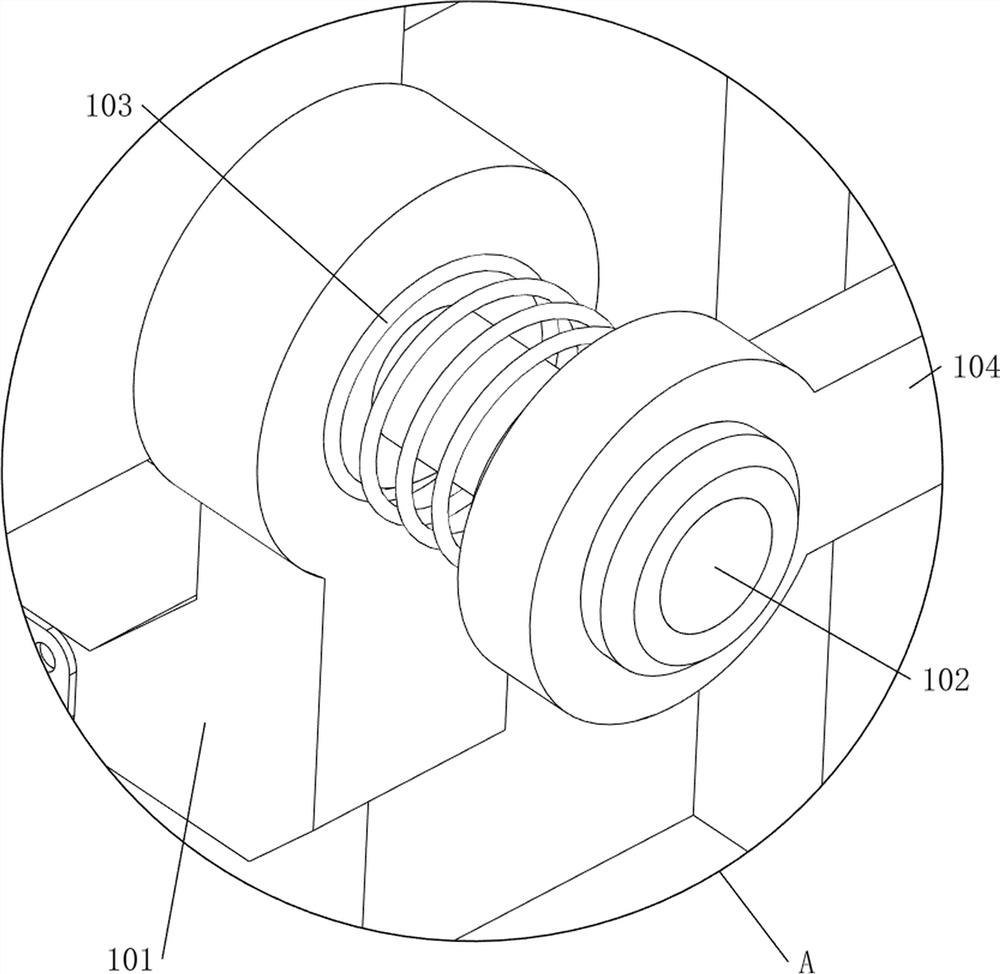

[0043] On the basis of Example 1, such as figure 1 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, a limit mechanism 8 is also included, and the limit mechanism 8 includes a slide rail 81, a second connecting rod 82, a first spring 83, a first support rod 84 and a limit block 85, which are located at the two second fixed frames 61 A slide rail 81 is placed on the left side of the inner side, and the middle part of the slide rail 81 has a card slot. The second connecting rod 82 is welded in the slide rail 81, and the first supporting rod 84 is movable on the second connecting rod 82. The first support rod 84 cooperates with the draw-in groove, the first spring 83 is sleeved on the second connecting rod 82, the left end of the first spring 83 links to each other with the slide rail 81, the first support rod 84 cooperates with the right end of the first spring 83, and the first support The upper side of the bar 84 is rotatably provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com