Production method of antistatic filter bag

A production method and antistatic technology, applied in separation methods, chemical instruments and methods, dispersed particle filtration, etc., can solve problems such as low production efficiency and complicated preparation methods, and achieve the effect of fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

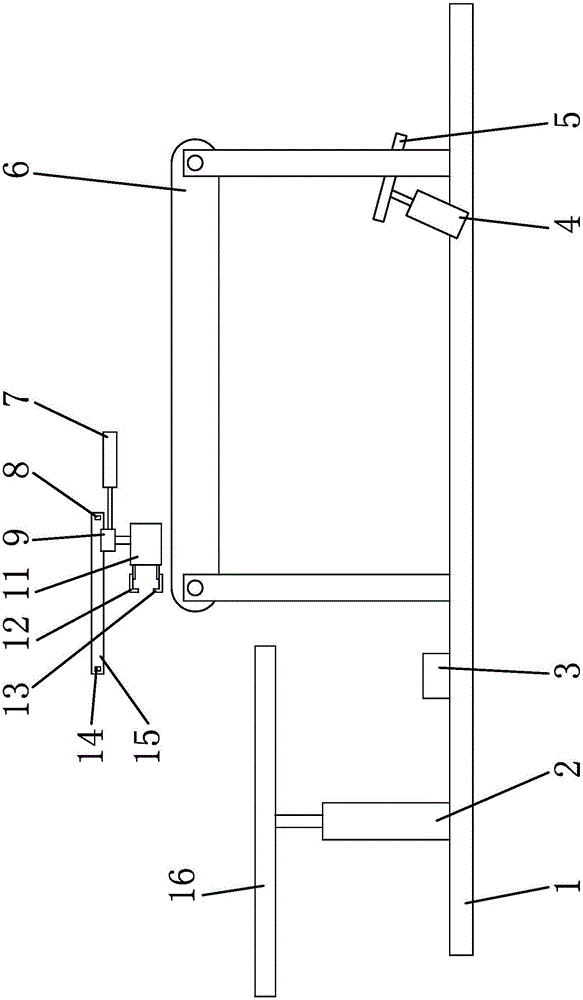

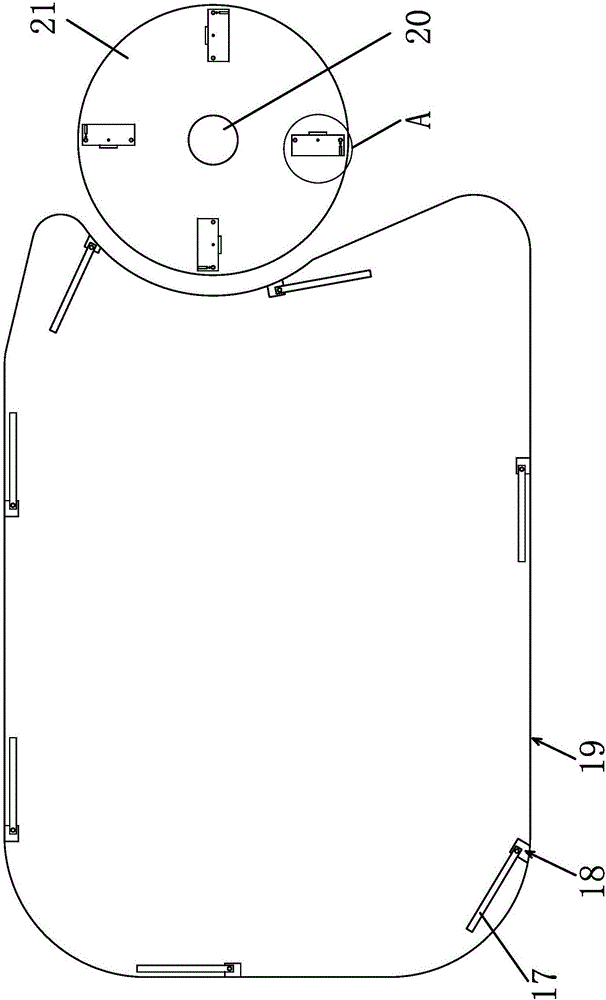

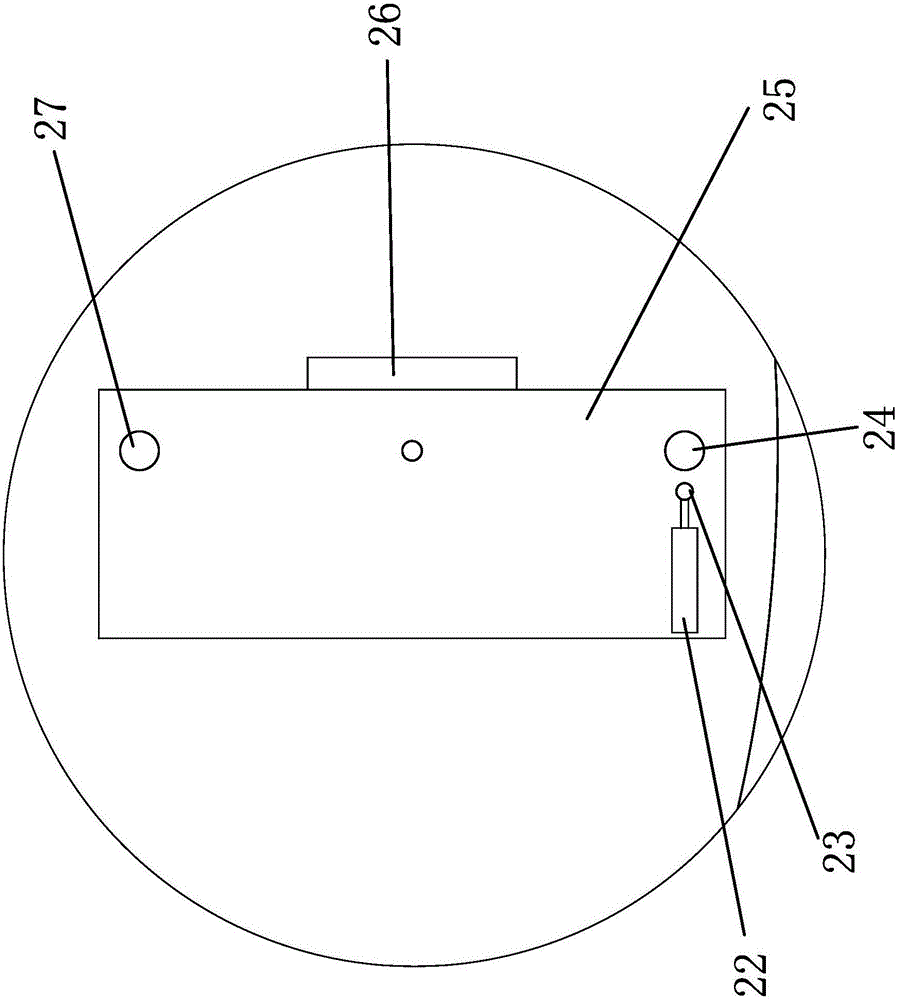

[0045] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0046] The manufacture method of this antistatic filter bag, this method comprises the following steps:

[0047] a. After opening, mixing, carding, laying and netting, the aramid fiber is added to the base cloth and needled to obtain a plain felt for filter material; in this embodiment, the aramid fiber is obtained from the market existing products;

[0048] b. Prepare treatment agent, each liter of treatment agent includes the following components: polytetrafluoroethylene emulsion 300-550ml / L, silicone water repellent agent 80-220ml / L, silane coupling agent 100-160ml / L and graphite milk 40-80ml / L, mix the raw materials in the formula evenly and add water to 1L; in this example, polytetrafluoroethylene emulsion 400ml / L, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com