Non-woven fabric slitting, folding and conveying device

A conveying device, non-woven technology, applied in conveyors, transportation and packaging, folding thin materials, etc., can solve the problems of low efficiency, increase labor costs, increase labor volume, etc., and achieve high efficiency and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

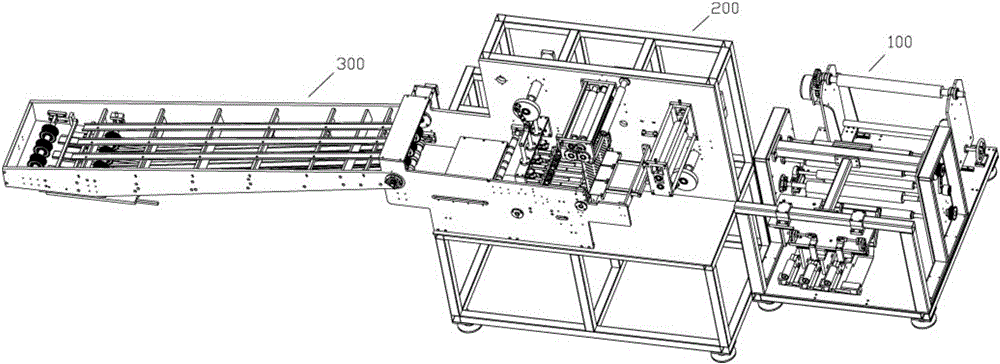

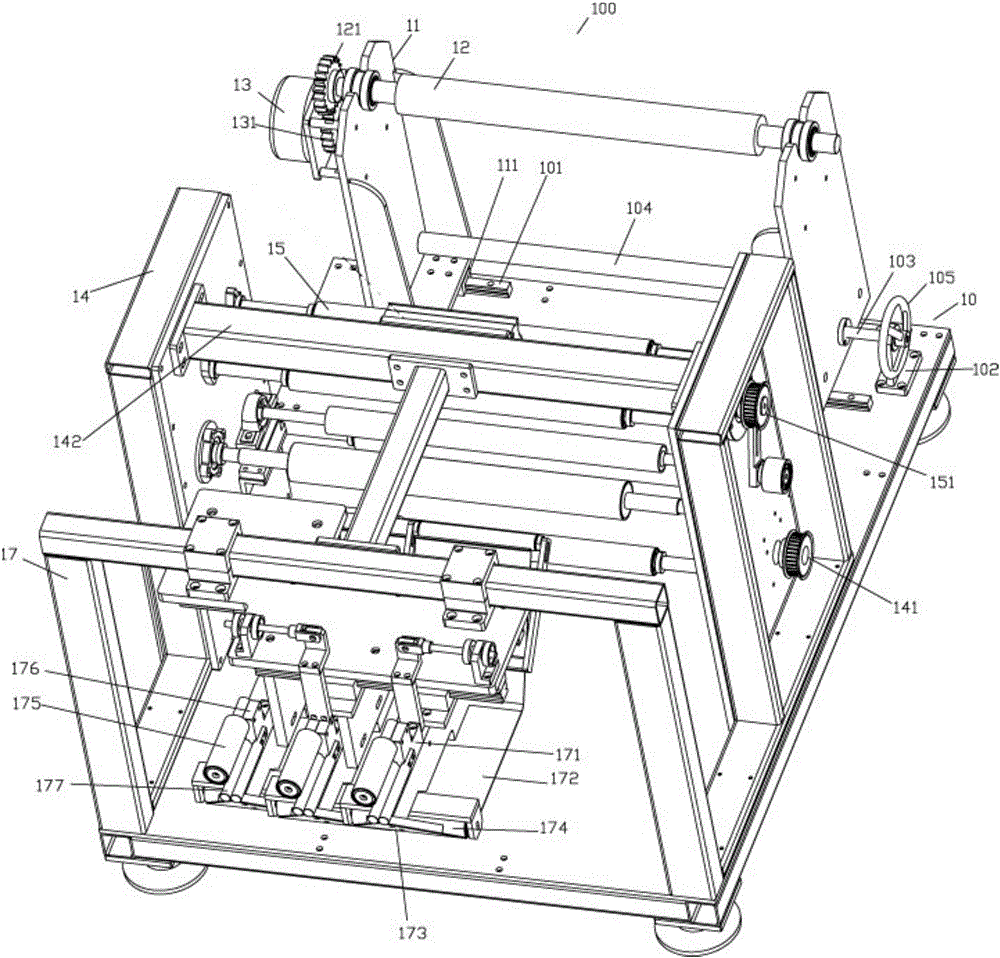

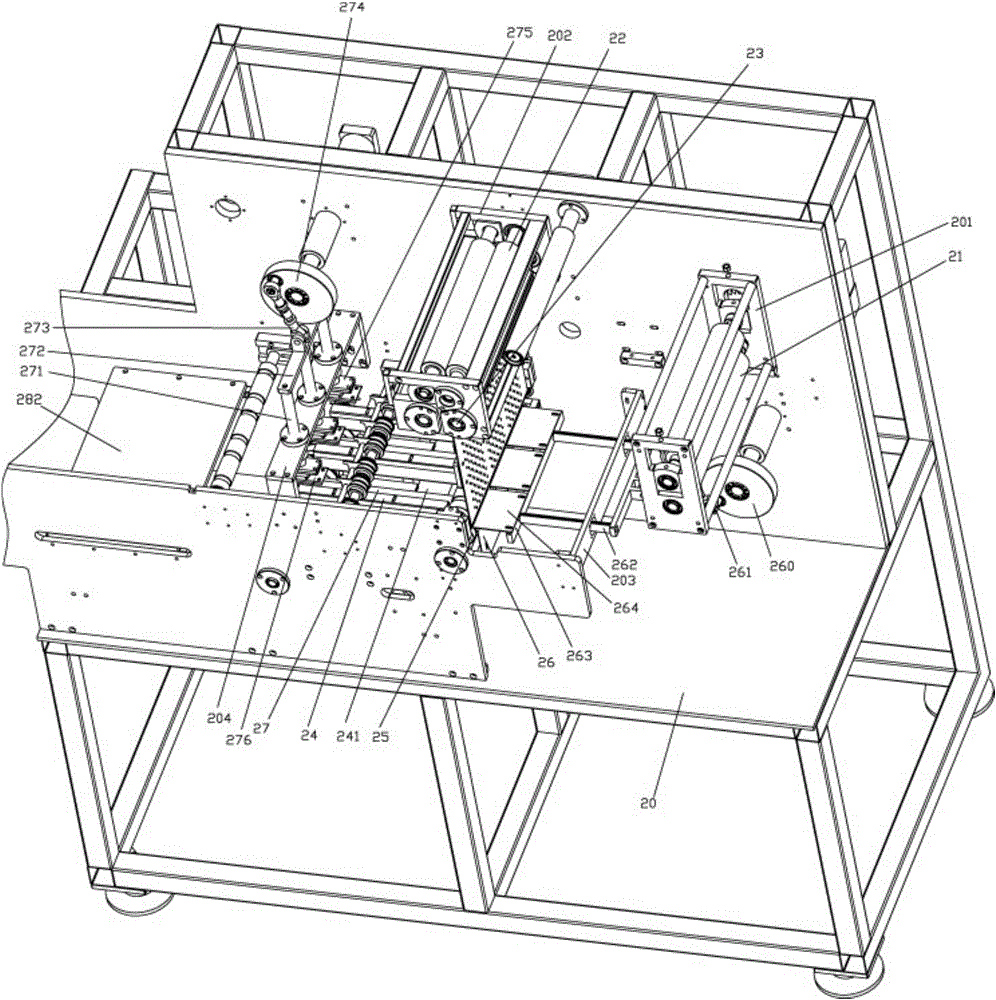

[0028] Examples, see e.g. Figures 1 to 10 As shown, a non-woven fabric cutting and folding conveying device includes a cutting mechanism 100, a folding mechanism 200 and a conveying mechanism 300;

[0029] Described slitting mechanism 100 comprises slitting frame 10, and the rear portion top of slitting frame 10 is provided with two feeding boards 11, and the two ends of feeding roller 12 are hinged on two feeding boards 11, and feeding roller 12 One end of the drive gear 121 is fixed, one of the feeding plates 11 is fixed with a drive servo motor 13, the output shaft of the drive servo motor 13 is fixed with a drive gear 131, the drive gear 131 is meshed with the drive gear 121, and the cutting mechanism 100 There are two cutting intermediate support plates 14 fixed in the middle of the center, and a plurality of transmission rollers 15 are hinged on the two cutting intermediate support plates 14, and a servo motor is fixed on one of the cutting intermediate support plates 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com