Environment friendly oil pipeline processing equipment

A technology for oil pipelines and processing equipment, which is applied in the field of environment-friendly oil pipeline processing equipment, can solve problems such as wasting manpower handling costs and efficiency, affecting oil quality, and troublesome large-scale equipment, so as to save manpower and material costs, improve work efficiency, and realize The effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

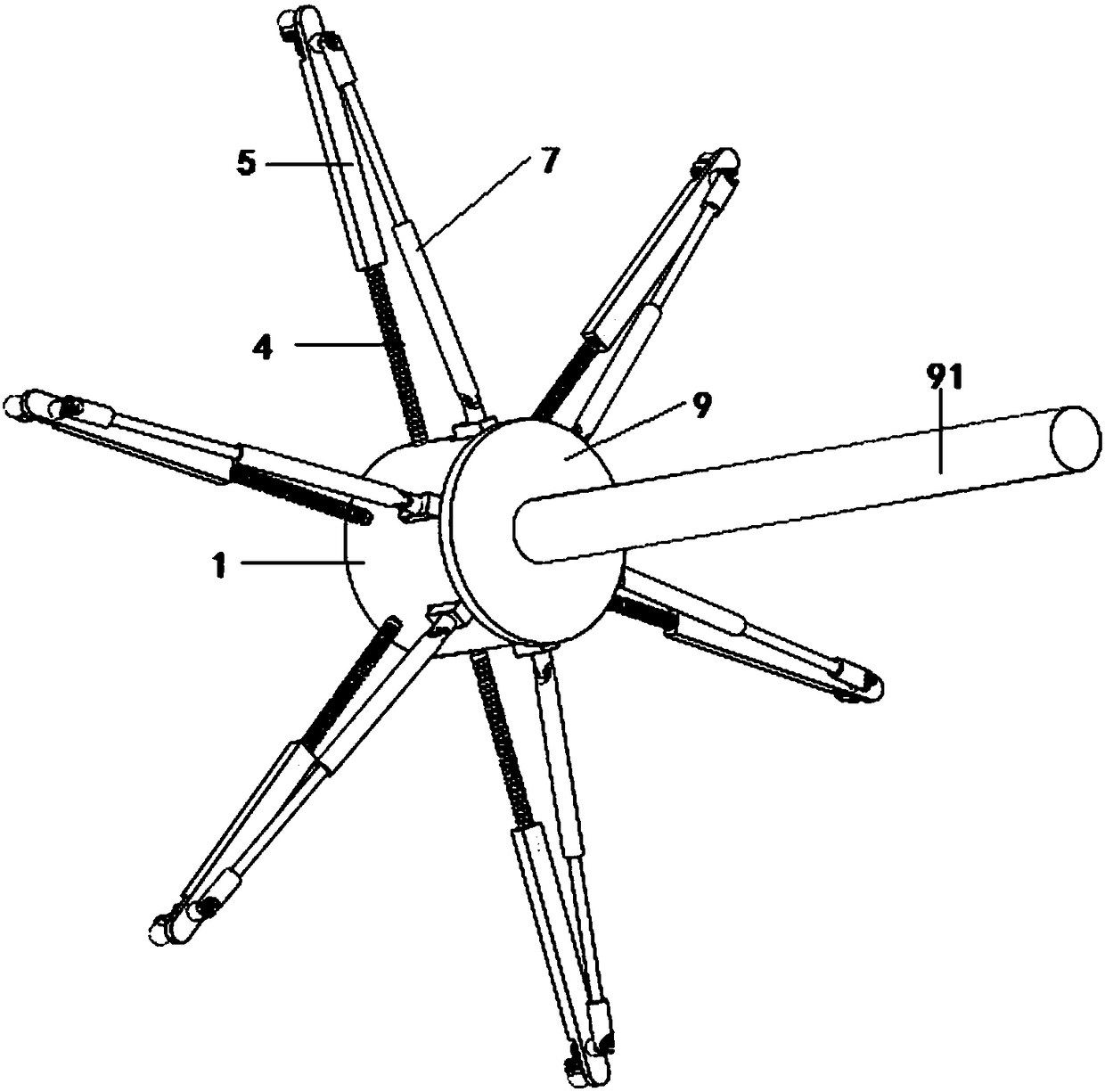

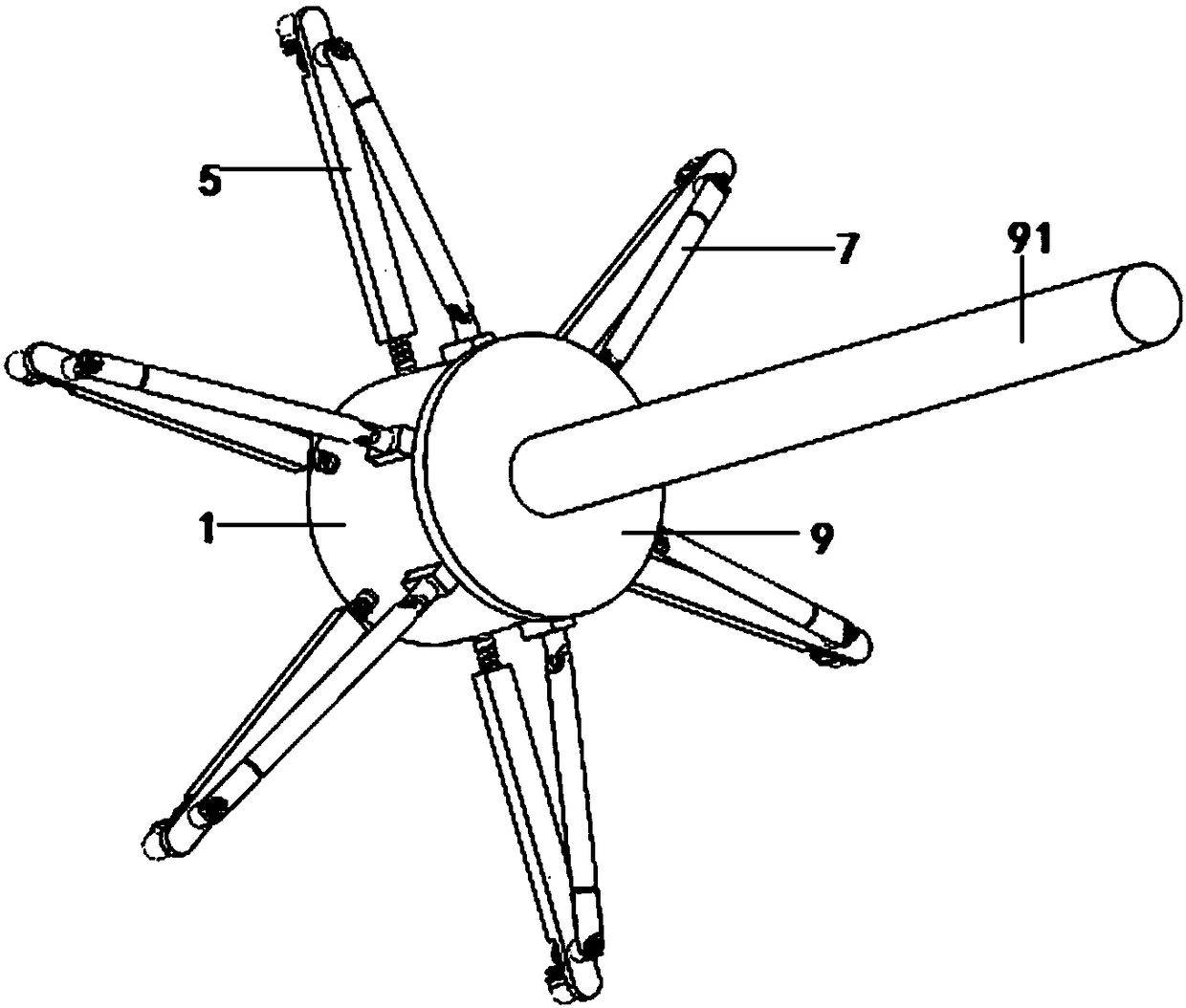

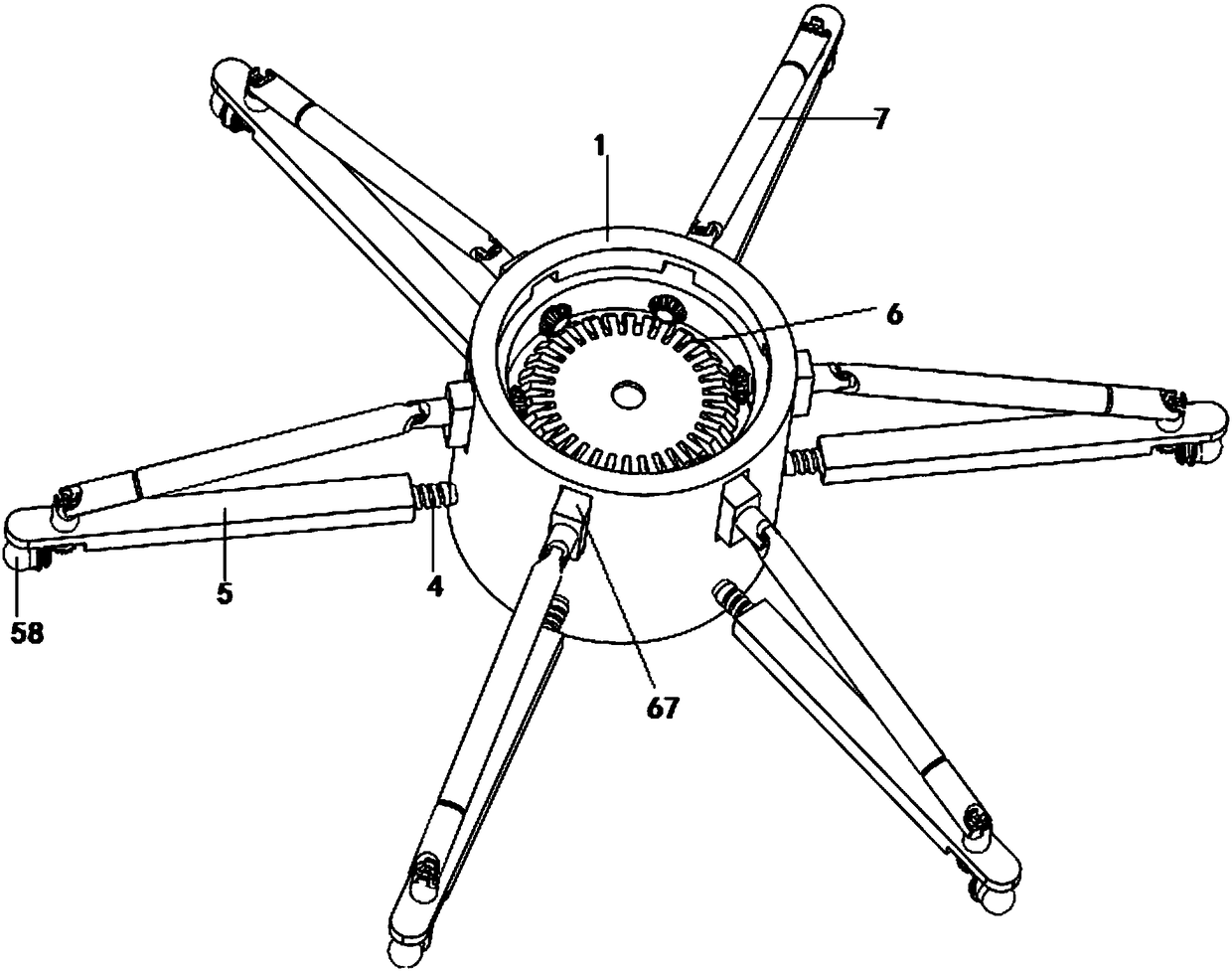

[0029] An environment-friendly oil pipeline processing equipment, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, it includes the chamfering and burring device for the inner wall of the oil pipeline. The flow rate of the oil, and the impurities in the oil are easy to accumulate on the chamfers and burrs, which will also affect the flow rate after long-term use. At the same time, the accumulated impurities are not easy to remove on the inner wall of the oil delivery pipe. The flow in the pipeline is smooth; the device includes a positioning and fixing cylinder 1, the middle part of the inner surface of the side wall of the positioning and fixing cylinder 1 is integrally connected and fixed with a horizontally distributed fixing plate 11, and the center of the surface of the fixing plate 11 is fixed with a first rotating shaft 12 , the top of the first rotating shaft 12 is fixed with a tooth sleeve seat 2, and the bottom is fixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com