Preparation method for diatom ooze

A technology of diatom mud and diatomite, applied in grain processing and other directions, can solve the problems of slow production speed, complicated preparation method steps, etc., and achieve the effects of fast production speed, avoiding clogging and good working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0057] The preparation method of this diatom ooze is raw material with diatomite, and the method comprises the following steps:

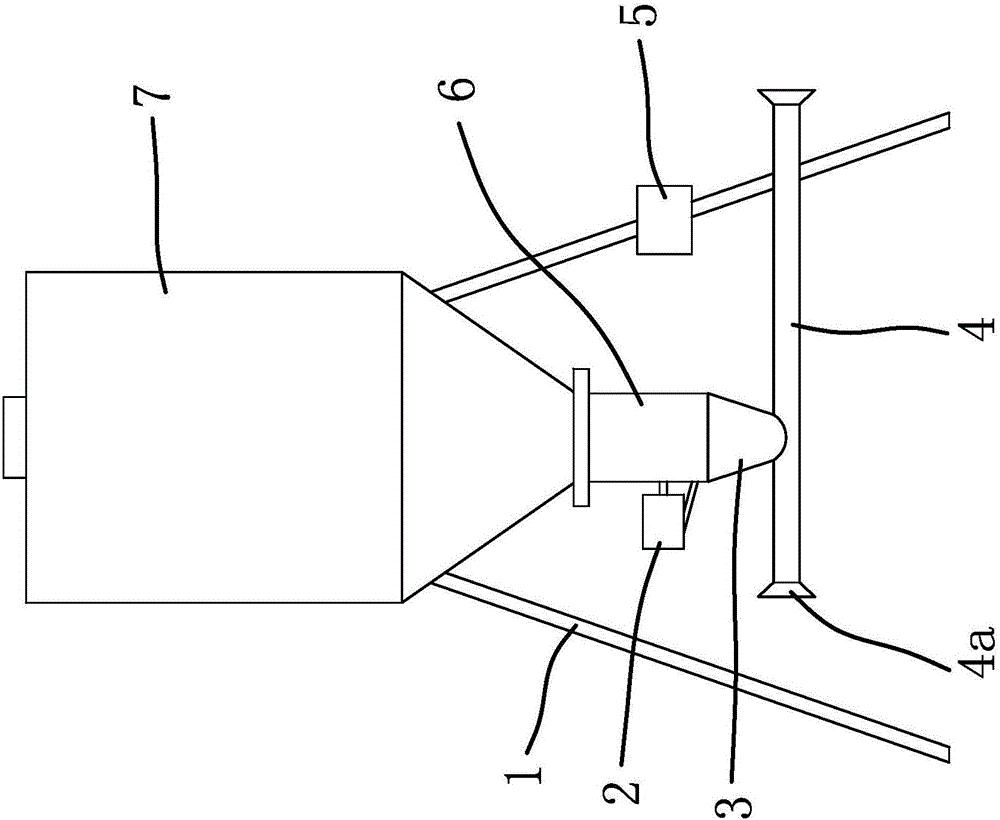

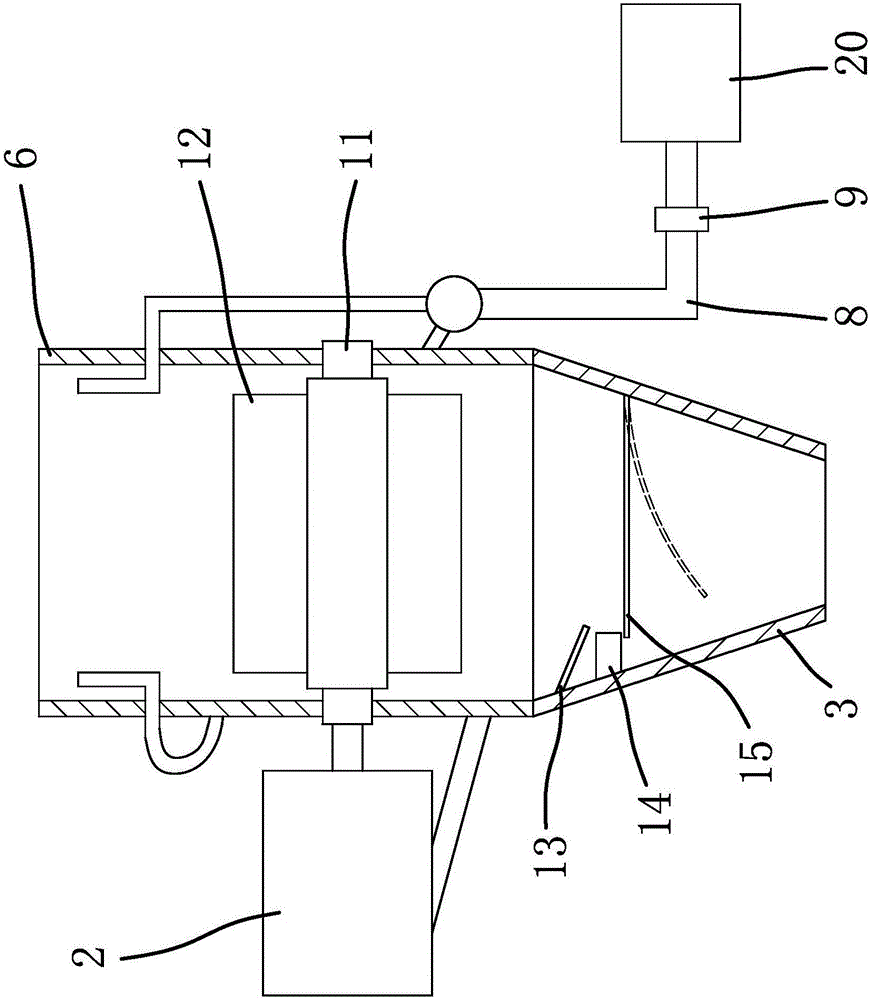

[0058] a. Jet milling: put diatomite into the jet milling system, and through the action of airflow, diatomite collides with each other to realize pulverization, reaching 3000-3500 mesh, in this embodiment, reaching 3200 mesh;

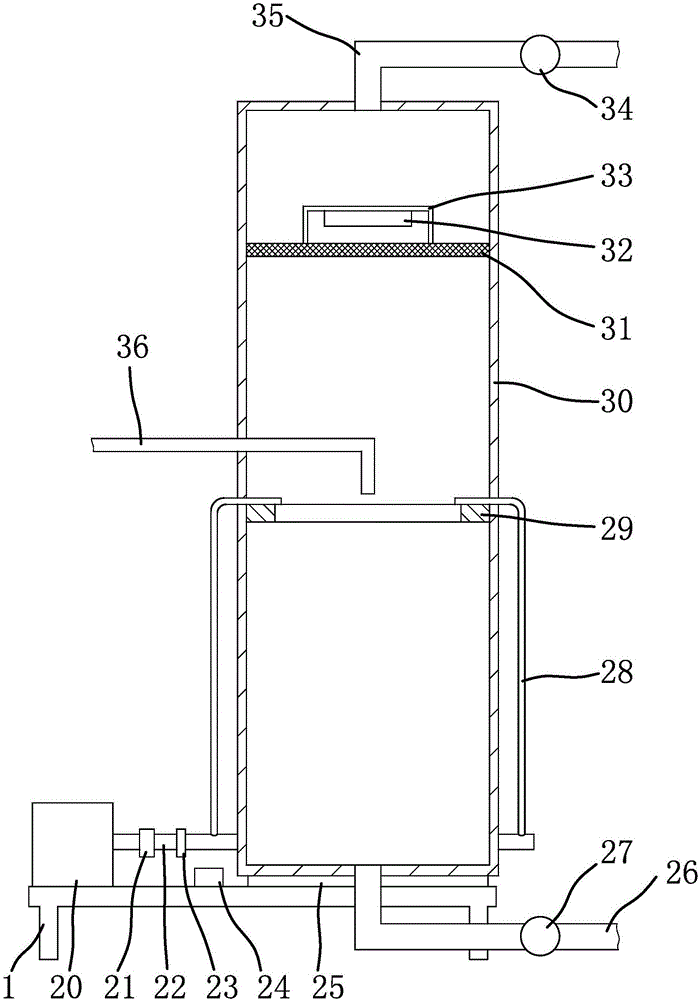

[0059] b. Screening: put the crushed diatomite in step a into an ordinary reaction kettle, and use free fall to screen the diatomite. Diatomite is collected, and in the present embodiment, diatomite is collected after diatomite falls 55s;

[0060] c. Pre-mixing of additives: Additives include inorganic toner, food cellulose, inorganic glue and white sand. Pour the inorg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com