Improved blended fabric processing method

A technology of blended fabrics and processing methods, applied to chemical instruments and methods, devices for coating liquid on the surface, mixers, etc., can solve the problems of slow production speed, complicated steps, and time-consuming, etc., and achieve fast processing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

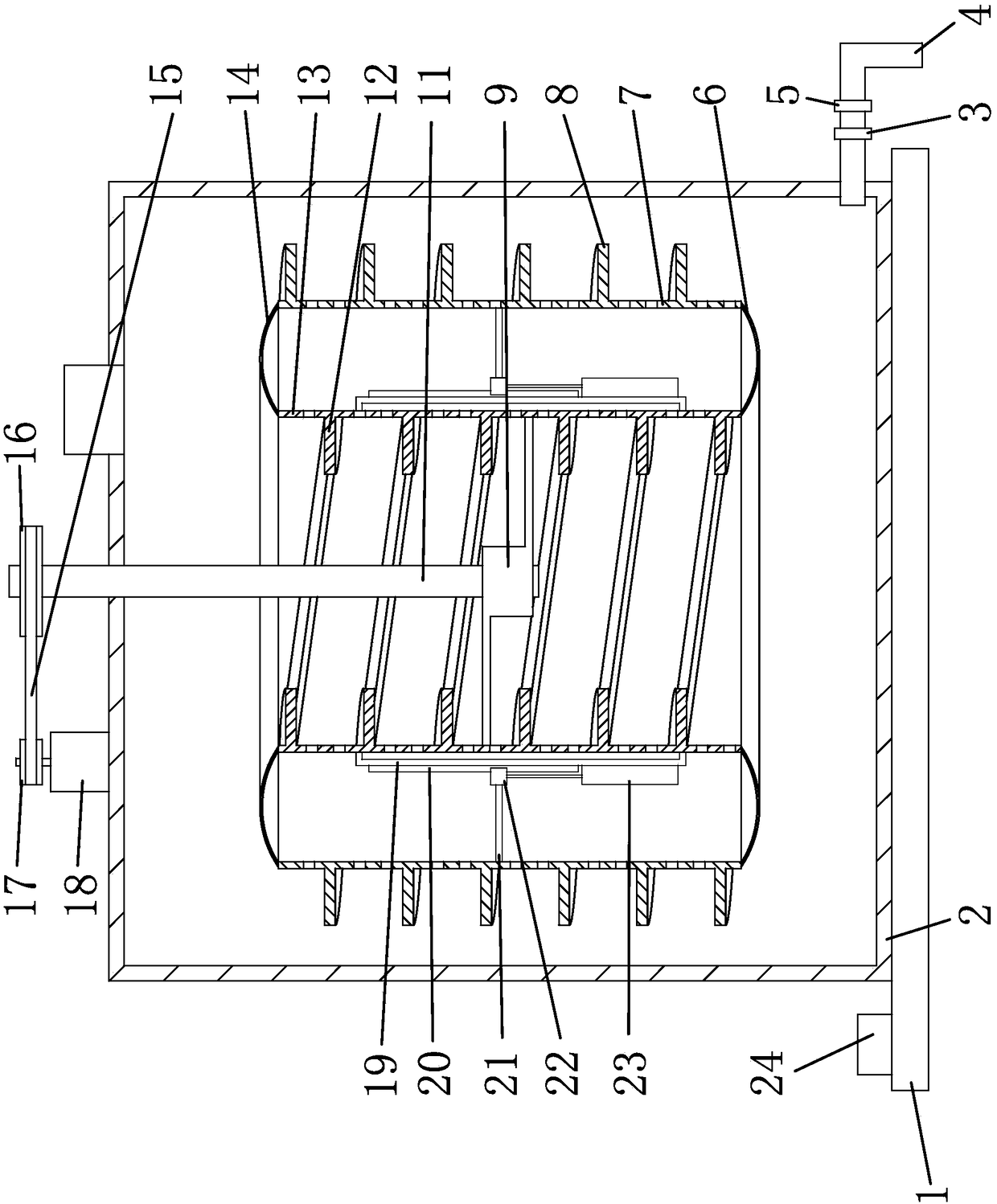

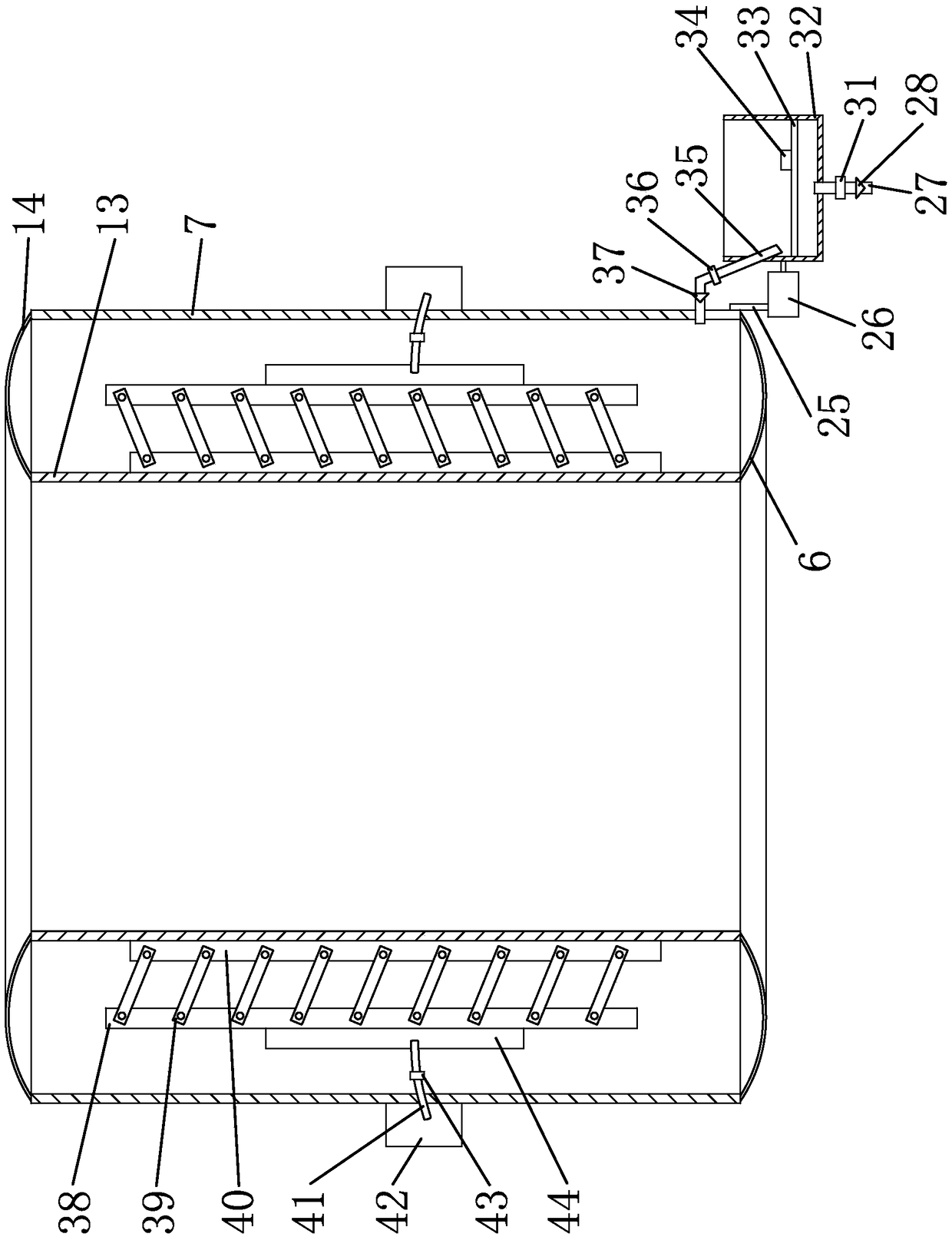

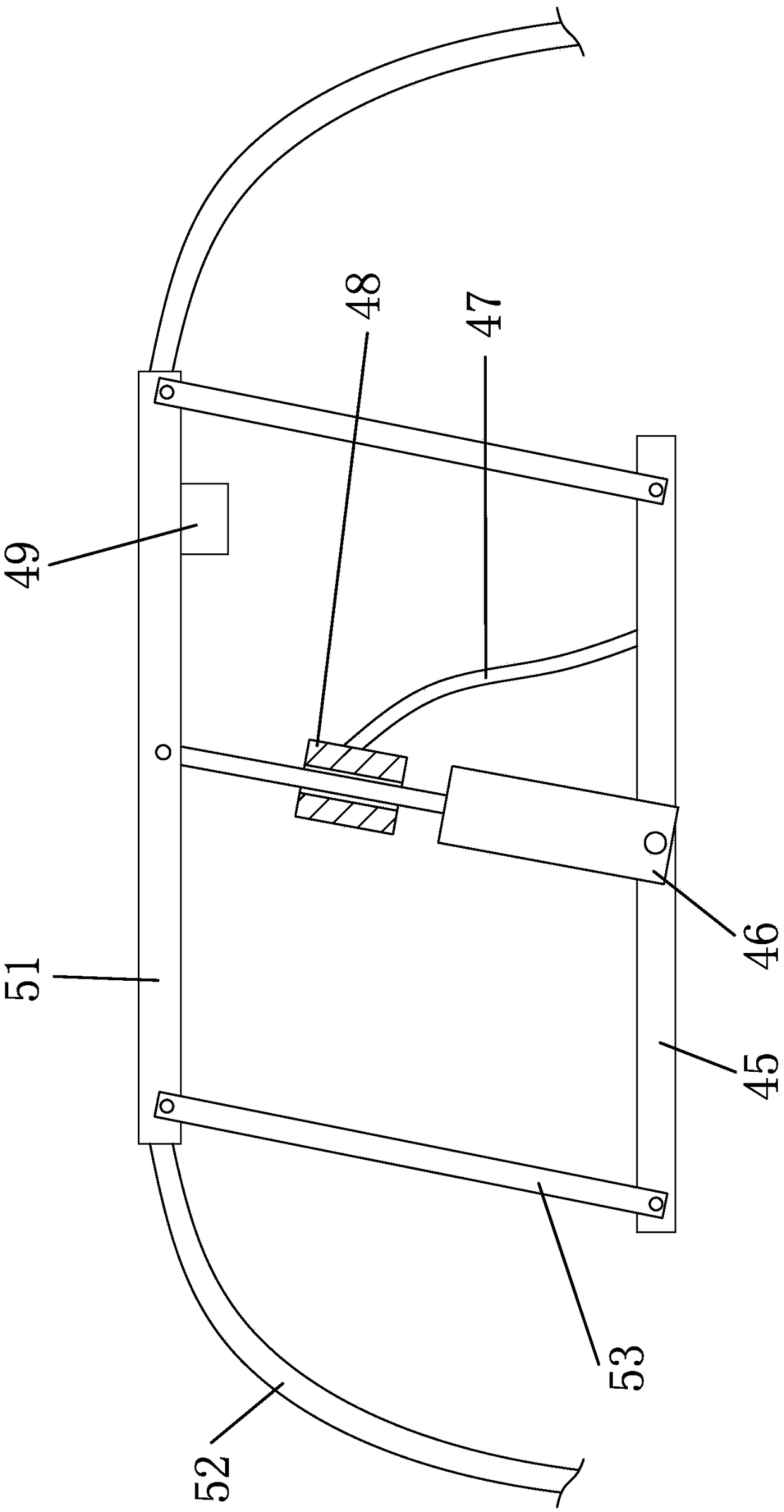

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0036] The processing method of this improved blended fabric comprises the steps:

[0037] a, get sea-island fiber and nylon fiber blended fabric, wherein, sea-island fiber accounts for 30-40% of the total weight of the fabric, and nylon fiber accounts for 60-70% of the total weight of the fabric; in the present embodiment, get sea-island fiber and nylon fiber blend Fabric, wherein sea-island fiber accounts for 35% of the total weight of the fabric, and nylon fiber accounts for 65% of the total weight of the fabric;

[0038] b. Weigh 20-30 parts of polyvinyl chloride, 15-20 parts of epoxy resin, 1-4 parts of titanium dioxide, 3-5 parts of nano-copper oxide, 0.8-1.6 parts of antifungal agent, and 1-3 parts of crosslinking a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com