Film containing graphene and/or graphene oxide, and preparation method thereof

A technology of graphene and thin film, which is applied in the field of thin film containing graphene and/or graphene oxide and its preparation, which can solve the problems of harsh solution requirements and waste of solution, and achieve the effect of fast preparation speed and saving solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

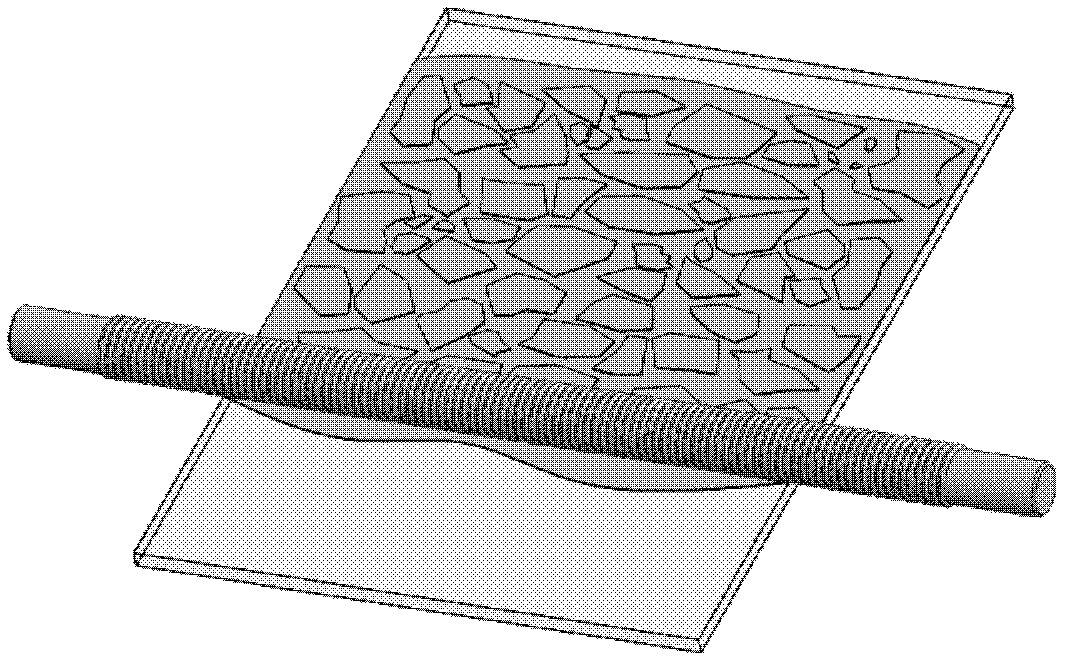

[0012] The invention provides a kind of preparation method that contains the thin film of graphene and / or graphene oxide, the method comprises the following steps: (1) graphene and / or graphene oxide sol is dispersed in solvent and is formulated into graphene and / or Or graphene oxide concentration is the dispersion liquid containing graphene and / or graphene oxide of 0.01-20mg / ml; (2) adopt wire bar coating method to make dispersion liquid form uniform wet film on the substrate, wherein said wire The wire diameter of the wire rod used in the rod coating method is 0.01-2mm; (3) volatilize the solvent in the wet film obtained in the step (2).

[0013] According to the present invention, the solvent can be deionized water and / or an organic solvent, and the organic solvent can be various organic solvents that can dissolve graphene and / or graphene oxide sol and are volatile, for example, it can be deionized In water, ethanol, methanol, acetone, ether, dimethyl ether, ethylene glycol,...

preparation example 1

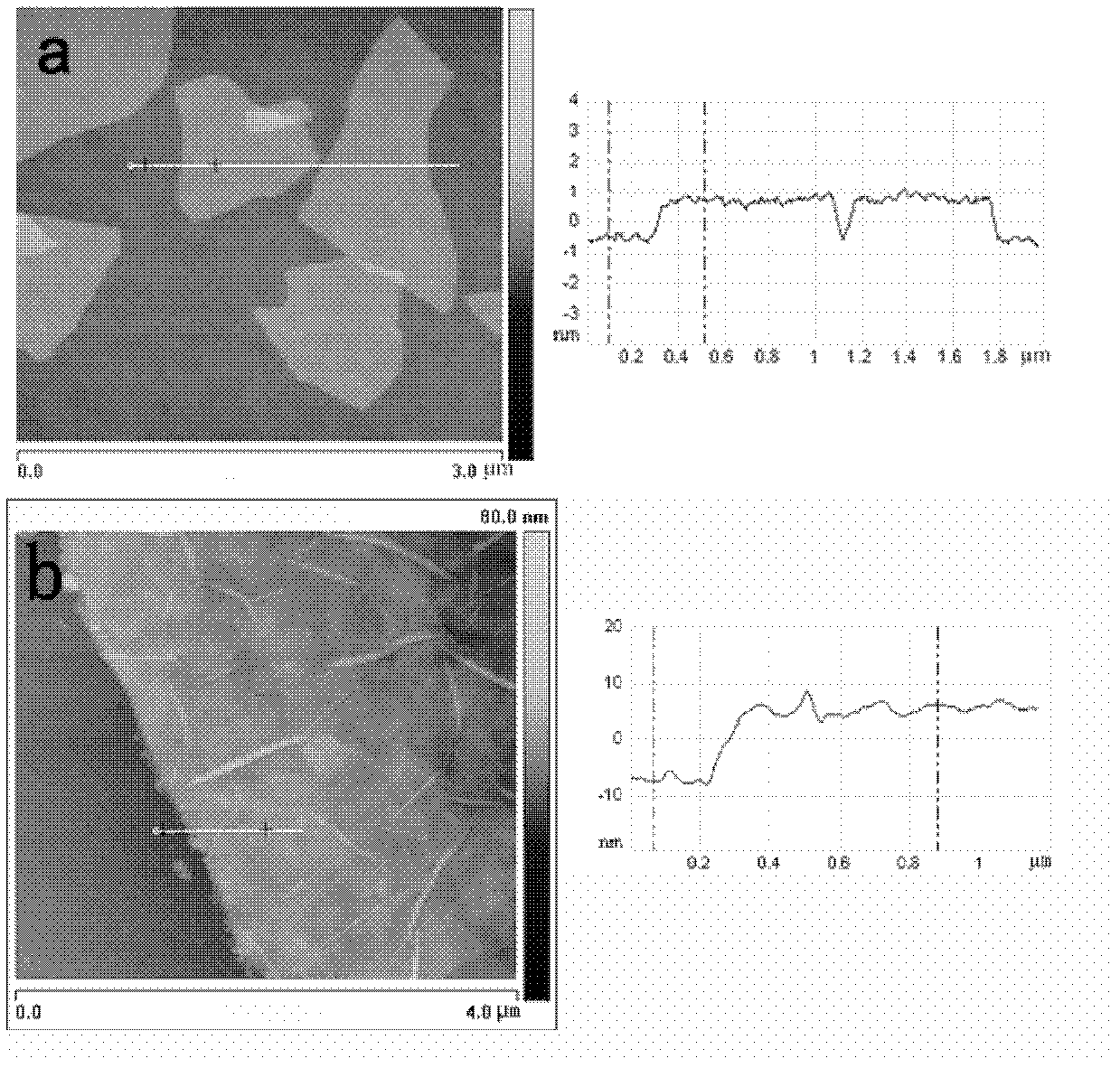

[0036] Treat natural graphite powder (1 part by mass) with concentrated sulfuric acid (30 parts by mass) and potassium permanganate (3 parts by mass) in an ice bath for 3 hours, raise the temperature to about 35°C, keep it for 30 minutes, and keep it at 95°C 45 parts by mass of water were added, and after 15 minutes of reaction, 3.5 parts by mass of 30% by weight hydrogen peroxide and 26.5 parts by mass of water were added to obtain a bright yellow suspension. Filter the suspension, wash the filter cake 3 times with 3% by weight hydrochloric acid, dry the obtained filter cake at 60°C, disperse the obtained filter cake in water to obtain a graphene oxide sol, centrifuge the sol, and redisperse After multiple treatments (generally more than 3 times), a relatively pure graphene oxide sol (wherein the content of graphene oxide is 20 mg / ml by weight %) is obtained, which is used to prepare a film containing graphene oxide.

preparation example 2

[0038] Add heat-expandable graphite powder or microcrystalline graphite or natural graphite (1 part by mass) to N-methylpyrrolidone solvent (1000 parts), and sonicate for 30 minutes in a 300w power ultrasonic instrument. The obtained dispersion was centrifuged at 500 rpm for 60 min using a centrifuge. The thick graphite flakes at the bottom were discarded to obtain a gray sol in the upper layer. The gray sol in the upper layer was centrifuged at a speed of 5000 rpm, and a black graphene sol (wherein the content of graphene was 1 mg / ml by weight %) was obtained at the bottom, which was used to prepare a graphene-containing film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com