Method for manufacturing high-intensity internal multi-tooth hexagonal-head flange-face bolt

A flange face bolt and manufacturing method technology, applied to bolts, threaded fasteners, connecting components, etc., can solve the problems of difficult processing, waste of raw materials, and numerous processes, and achieve high production efficiency, quality assurance, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

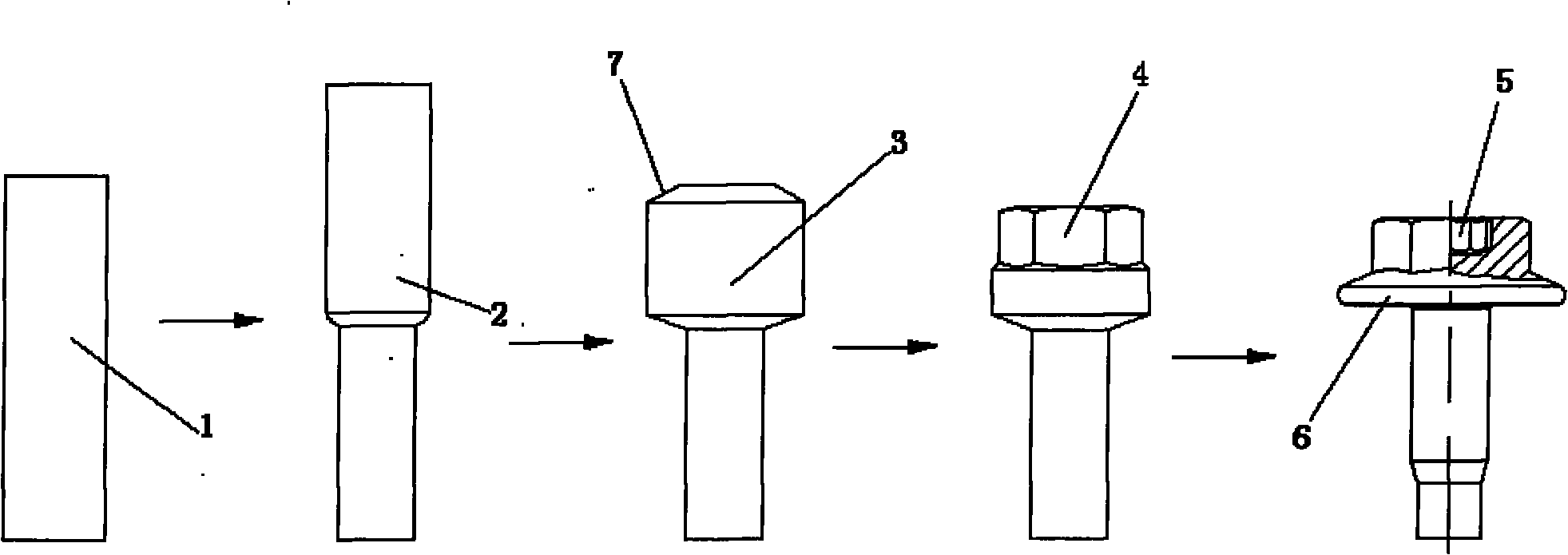

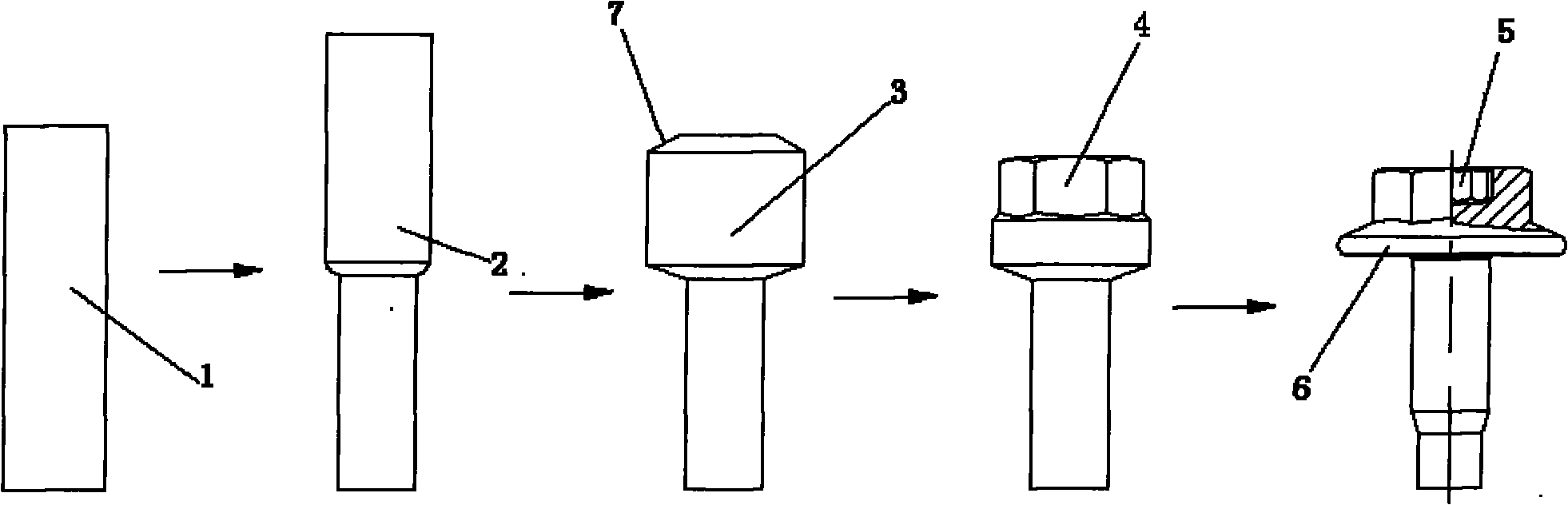

[0014] see figure 1 , a method for manufacturing high-strength internal multi-tooth hexagon head flange bolts, firstly phosphate surface-treating the round material of high-strength internal multi-tooth hexagon head flange bolts, and then roughing the high-strength internal The raw material of multi-tooth hexagon head flange bolts is subjected to spheroidizing annealing, phosphate film treatment, fine drawing and sizing, and finally cold heading forming treatment process, including the following steps:

[0015] 1) Automatically cut the disc round material 1 after precision drawing and sizing into a single high-strength internal multi-tooth hexagon head flange bolt blank 2 in the cold heading machine;

[0016] 2) Send the high-strength internal multi-tooth hexagonal head flange bolt blank 2 into the cold heading machine, shrink the rod to form the tapping diameter of the threaded part, and form a chamfer 7 at the joint;

[0017] 3) Flip the two ends of the high-strength intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com