Sand mould composite molding equipment

A technology of composite forming and equipment, which is applied in the direction of casting forming equipment, casting mold components, metal processing equipment, etc., can solve the problems of processing method restrictions, and achieve the effect of improving forming efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

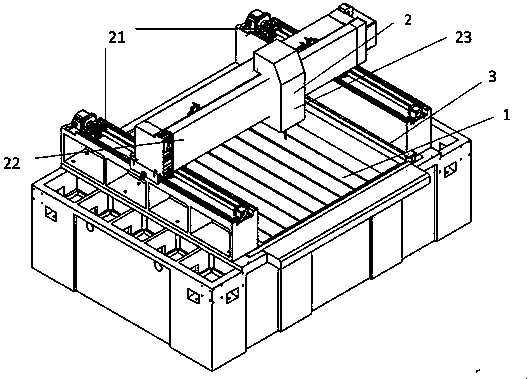

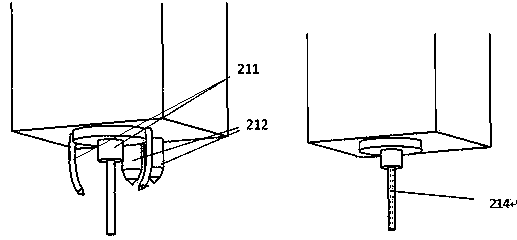

[0019] see Figure 1 to Figure 5 , schematically shows a preferred embodiment of a sand composite molding equipment provided by the present invention, such as figure 1 As shown, the composite sand molding equipment includes a multi-functional platform system 1, a planar motion system 2, a molding sand feeding system 3, a resin injection system 212, a cutting system 211, a cooling sand discharge system 213, and an exhaust dust collection system 4, etc. device.

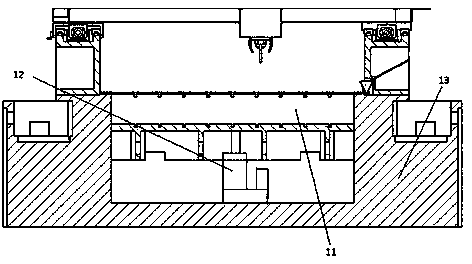

[0020] The multifunctional platform system 1 includes a working plate 11 that can move up and down, a vertical lifting system 12, and a fixed base 13. The working plate 11 is evenly distributed with T-shaped groove structures, which is convenient for the clamping of the mold during cutting. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com