F-shaped molding production line, F-shaped molding production method and V technique casting method

A production line and station technology, applied in casting molding equipment, casting molds, cores, etc., can solve the problems of wasting waiting time for mobile vibrating platforms, underutilizing component capacity, and reducing the efficiency of V-method casting, so as to reduce the overall The effect of modeling time, smooth modeling process and shorter working interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

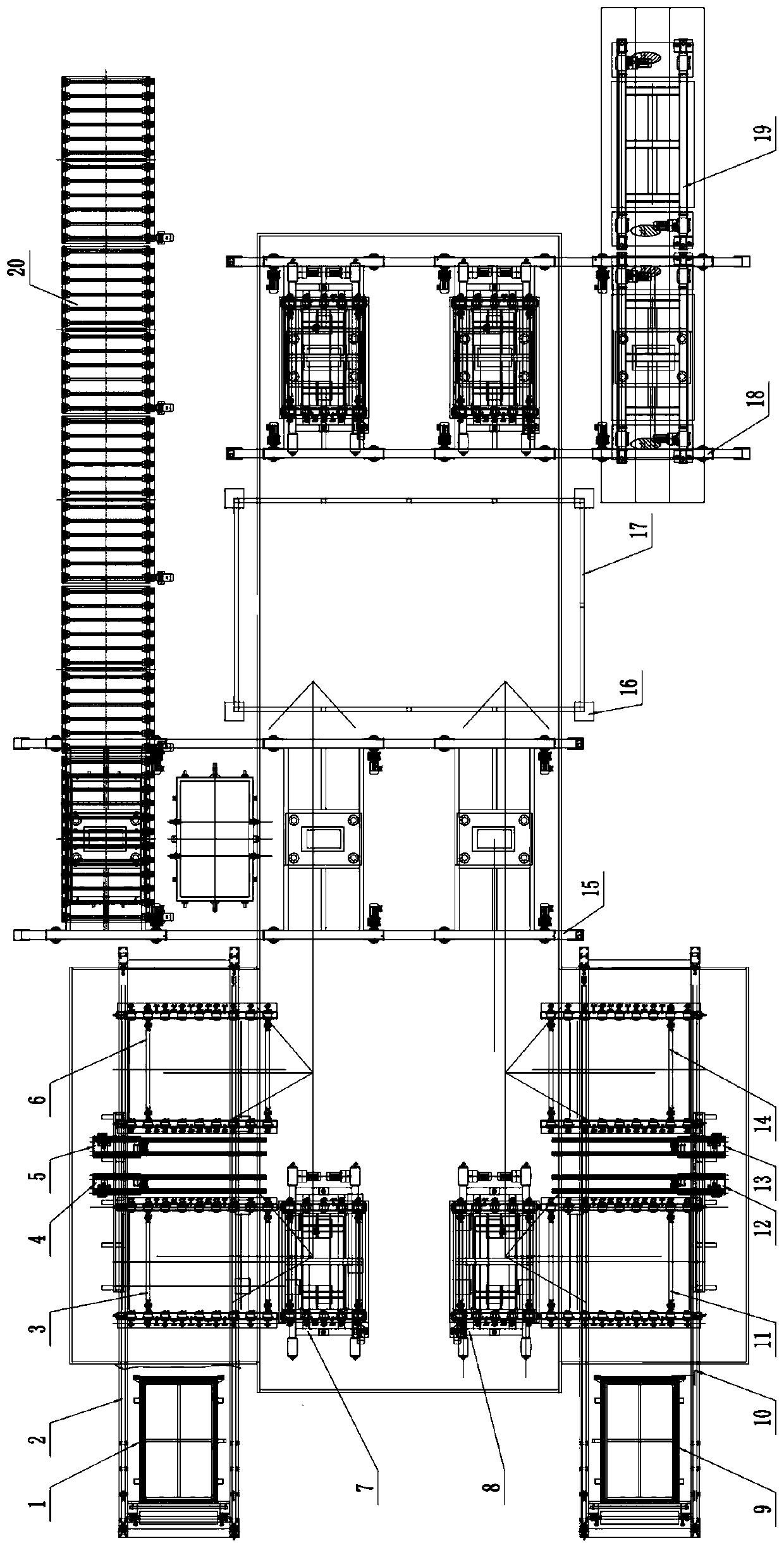

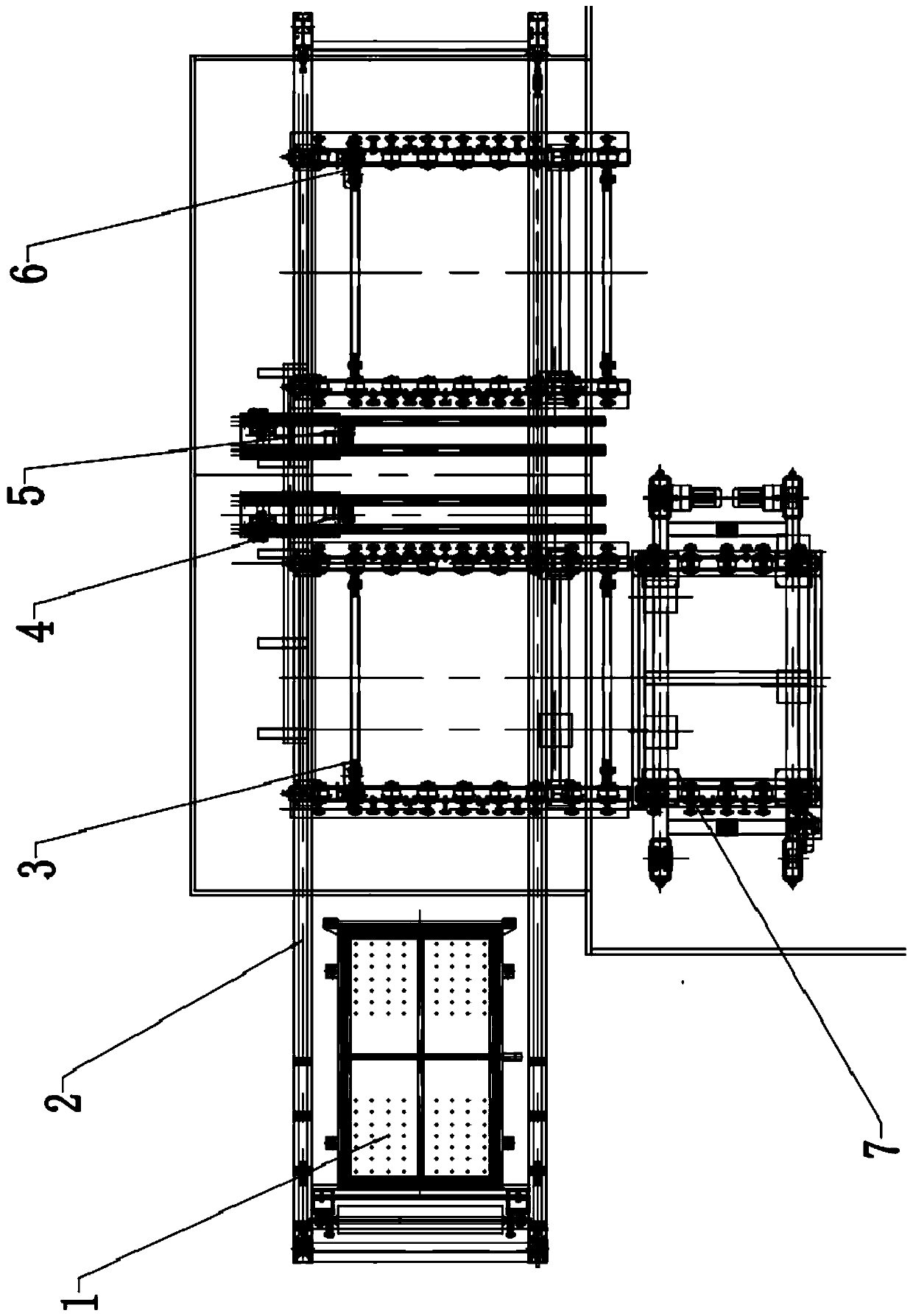

[0050] A typical embodiment of the present invention: as Figure 1-Figure 2 , Figure 4-Figure 15 Shown, a kind of F shape molding production line.

[0051] Such as figure 1 As shown, it includes the first guide rail and the second guide rail, and the first roller table 3, the second roller table 6, the empty box station, the rain sanding device and the film and box closing worker are arranged in sequence along the extending direction of the first guide rail. position, the first guide rail is equipped with a first trolley moving along it, and the first trolley carries a first vibrating platform 7; the first vibrating platform is used to receive the first roller table or the second roller The upper negative pressure box conveyed on the road, and drives the upper negative pressure box to pass through the empty box station successively. The empty box on the empty box roller table 20 uses the empty box manipulator 15 to empty the box, and the rain sand adding device 17 adds sand...

Embodiment 2

[0074] The present invention also provides a kind of production method that adopts the production line of embodiment 1:

[0075] Place the first upper negative pressure box and the second upper negative pressure box on the first roller table and the second roller table respectively, and place the first lower negative pressure box and the second lower negative pressure box on the third roller table and the second roller table respectively. On the four-roller table;

[0076] Use the first set of molds and the second set of molds, the first set of molds includes the first upper mold and the first lower mold, the second set of molds includes the first upper mold and the second lower mold; the first upper mold and the second The two upper molds are respectively placed on the first upper negative pressure box and the second upper negative pressure box and covered with film, and the first negative pressure trolley is used to evacuate the film so that the film is completely attached t...

Embodiment 3

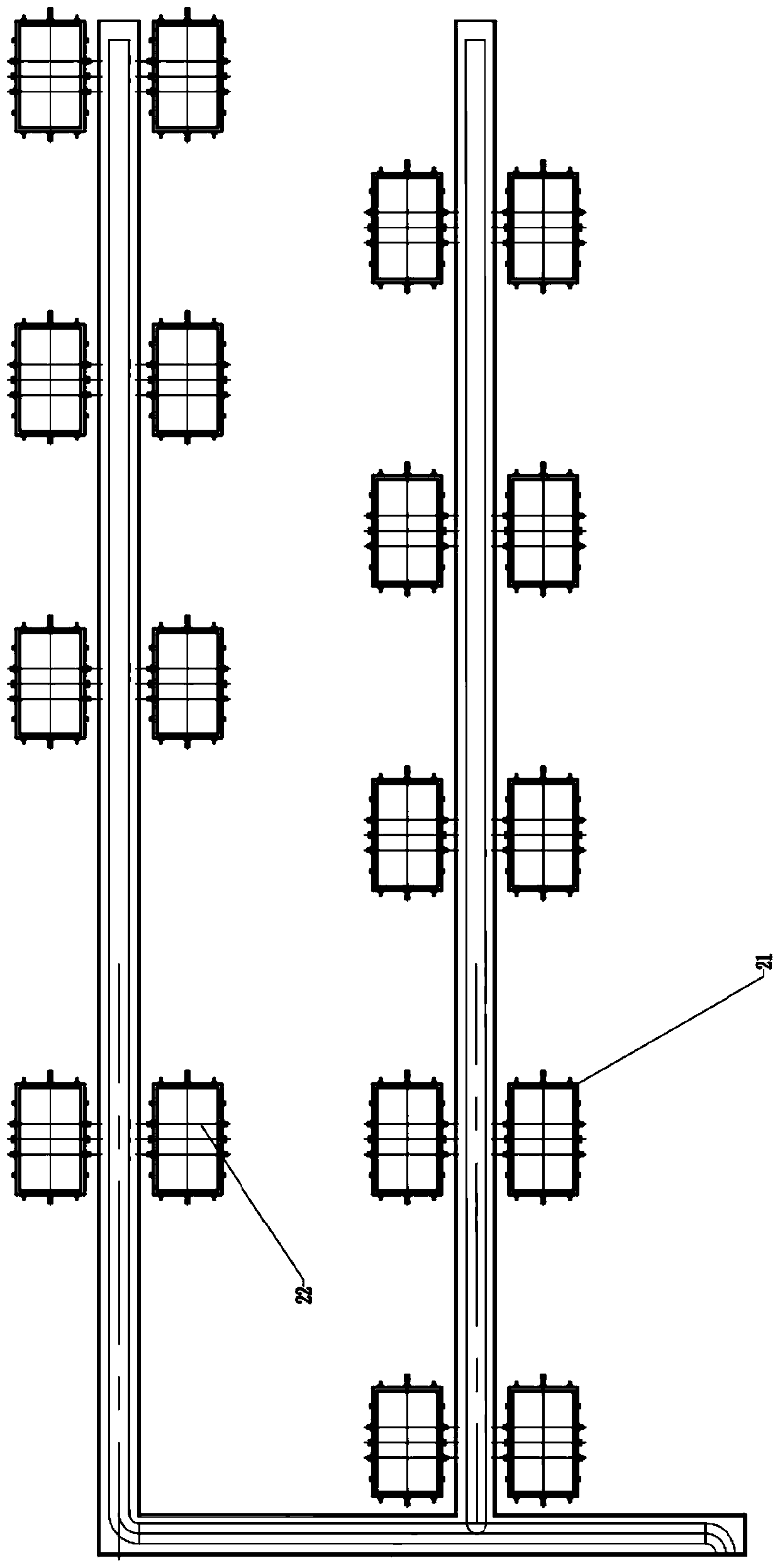

[0097] The present application also provides a V-method casting method, including a molding line, a pouring line 21 and a cooling line 22 .

[0098] The molding line described therein adopts the production method as described in embodiment 2 to carry out molding.

[0099] Further, such as image 3 As shown, the closing car transports the closed sand box to the pouring line for pouring, and sends the poured sand box to the cooling line for cooling. After cooling, remove the vacuum device, and directly drop the sand with the casting without vibration. After the sand is cooled, it returns to the system for recycling, and the castings are removed for cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com