Conveying method and device for conveying sand box set with temperature change through hydraulic cylinder

A technology of temperature change and hydraulic cylinder, which is applied in the field of sand box group, can solve problems such as difficult working speed, working distance, damage of casting equipment, failure to transport sand box to the specified position, etc., and achieve the effect of eliminating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below based on the drawings.

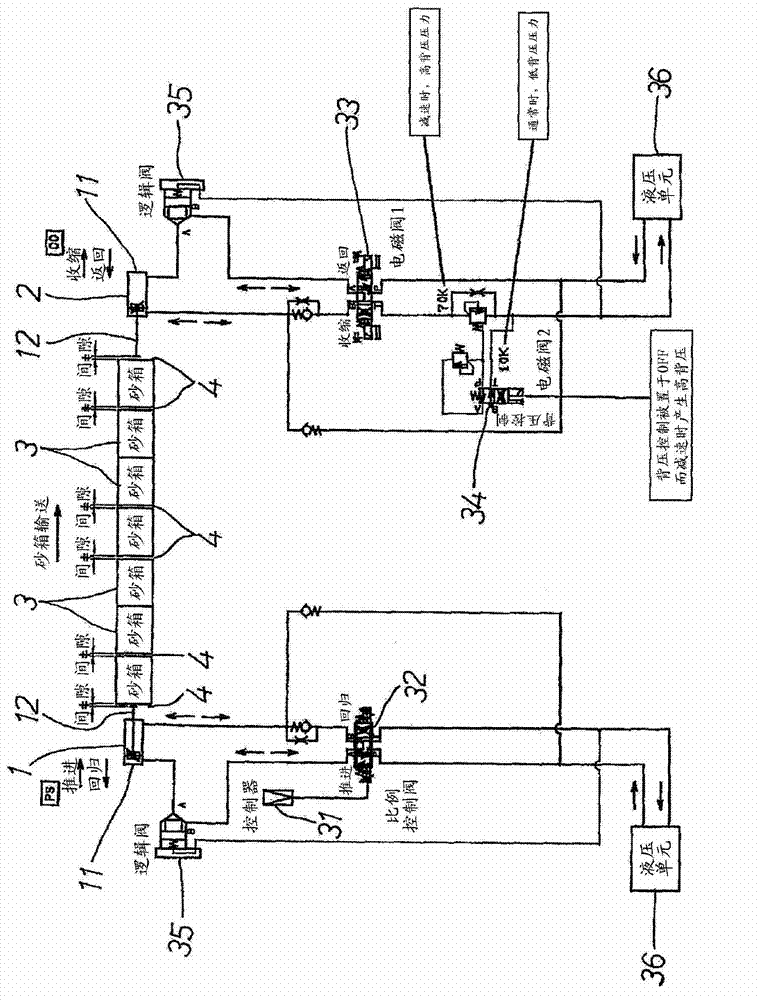

[0022] figure 1 A conveying line and a hydraulic piping system diagram showing a hydraulic push cylinder 1 and a hydraulic buffer cylinder 2 arranged opposite to each other to clamp the flask groups 3 and 3 and to convey intermittently a distance of one flask size at a time. There are various devices not shown in the figure between the hydraulic push cylinder 1 and the hydraulic buffer cylinder 2 , and gaps 4 , 4 are provided in front of each device and in front of the hydraulic push cylinder 1 and the hydraulic buffer cylinder 2 as shown in the figure. In addition, the hydraulic push cylinder 1 has a stroke substantially greater than the sum of these gaps 4 , 4 .

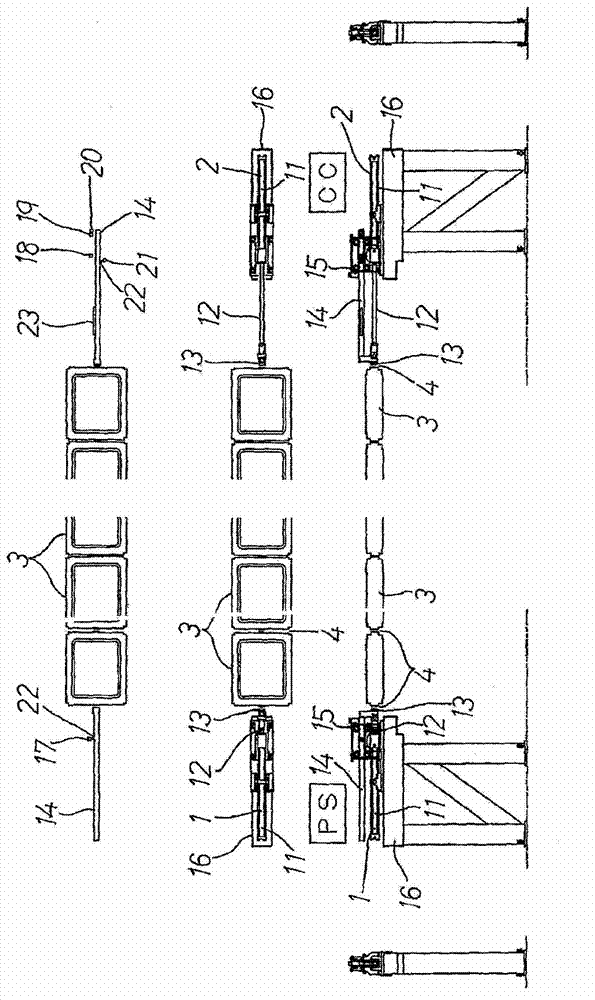

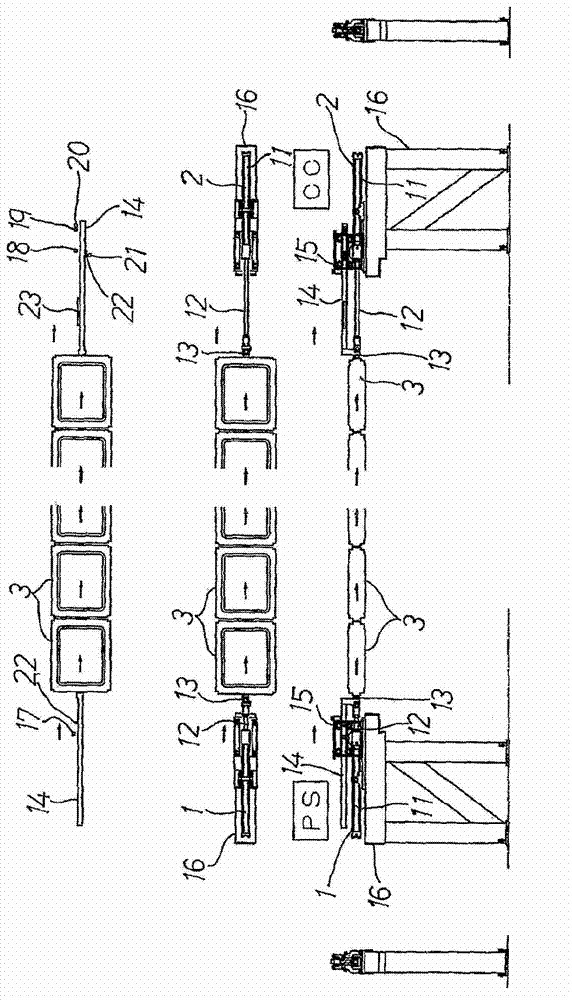

[0023] Such as Figure 2 ~ Figure 6 As shown, at the ends of the piston rods 12, 12 of the hydraulic push cylinder 1 and the hydraulic buffer cylinder 2, sand box push heads 13, 13 are installed, and guide rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com