Method for producing cylinder cover of compressor of heavy duty truck

The technology of a compressor cylinder and production method is applied in casting workshops, casting molds, cores, etc., which can solve the problems of difficulty in setting cores, large gas generation, and high rejection rate, and achieve the goal of reducing the total gas generation and consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

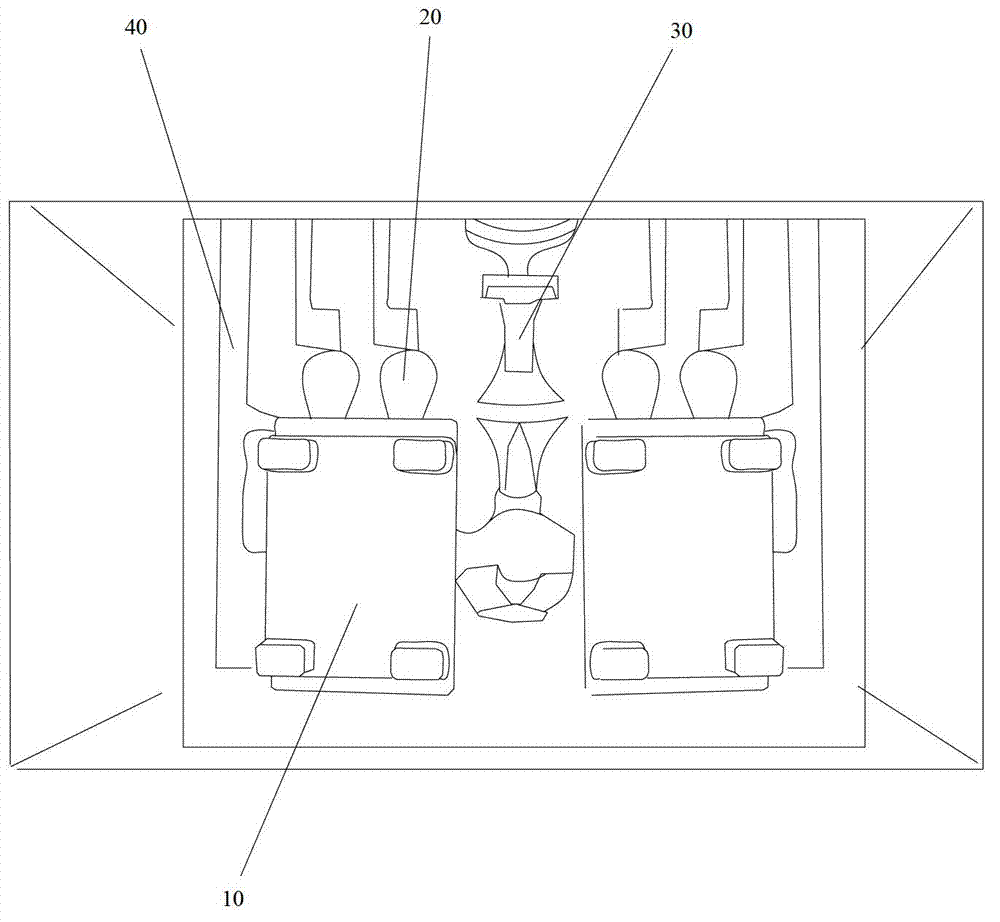

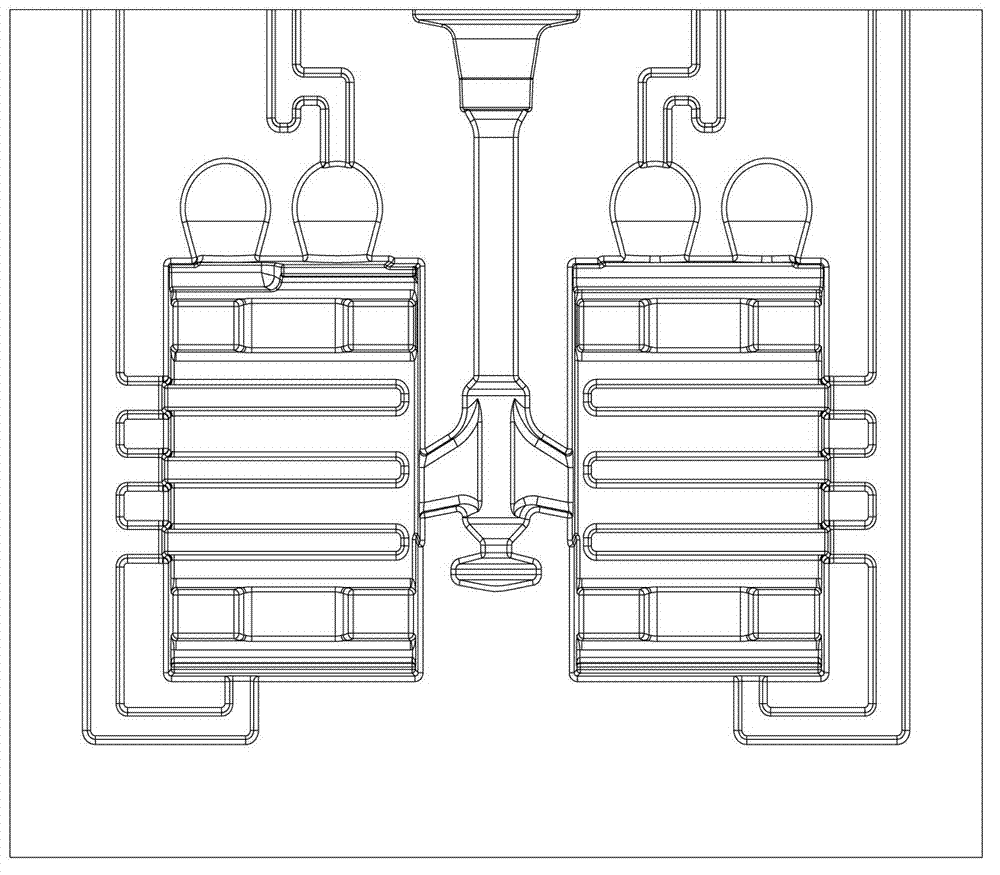

[0026] Such as figure 1 and 2 As shown, the method for producing the heavy truck cylinder head of the present invention is to adopt the continuous production process of the vertical molding line without a box, and the production steps included in the process are as follows:

[0027] 1) Use a core shooting mechanism to make sand cores, and combine the prepared sand cores to form the overall shell shape 10 of the casting;

[0028] 2) Make the sand mold on the production line with the outer mold of the molding, that is, create the cavity for placing the overall shell mold of the casting and the sand mold 20 of the gating system, mainly to create the shell mold cavity for forming the casting in step 1) and The sand mold of the sprue (sprue 20), runner, ingate and exhaust system 40 brought out by the outer mold molding;

[0029] 3) Lower the overall shell mold forming the casting into the sand mold made by the molding line for pouring to form a casting.

[0030] The sand mold pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com