Sound membrane module assembling equipment of loudspeaker

A technology for assembling equipment and loudspeakers, which is applied in the direction of sensors and electrical components, can solve the problems of inconsistent operation process, low production efficiency, and unguaranteed processing quality, so as to reduce labor costs, improve production efficiency, and high yield rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

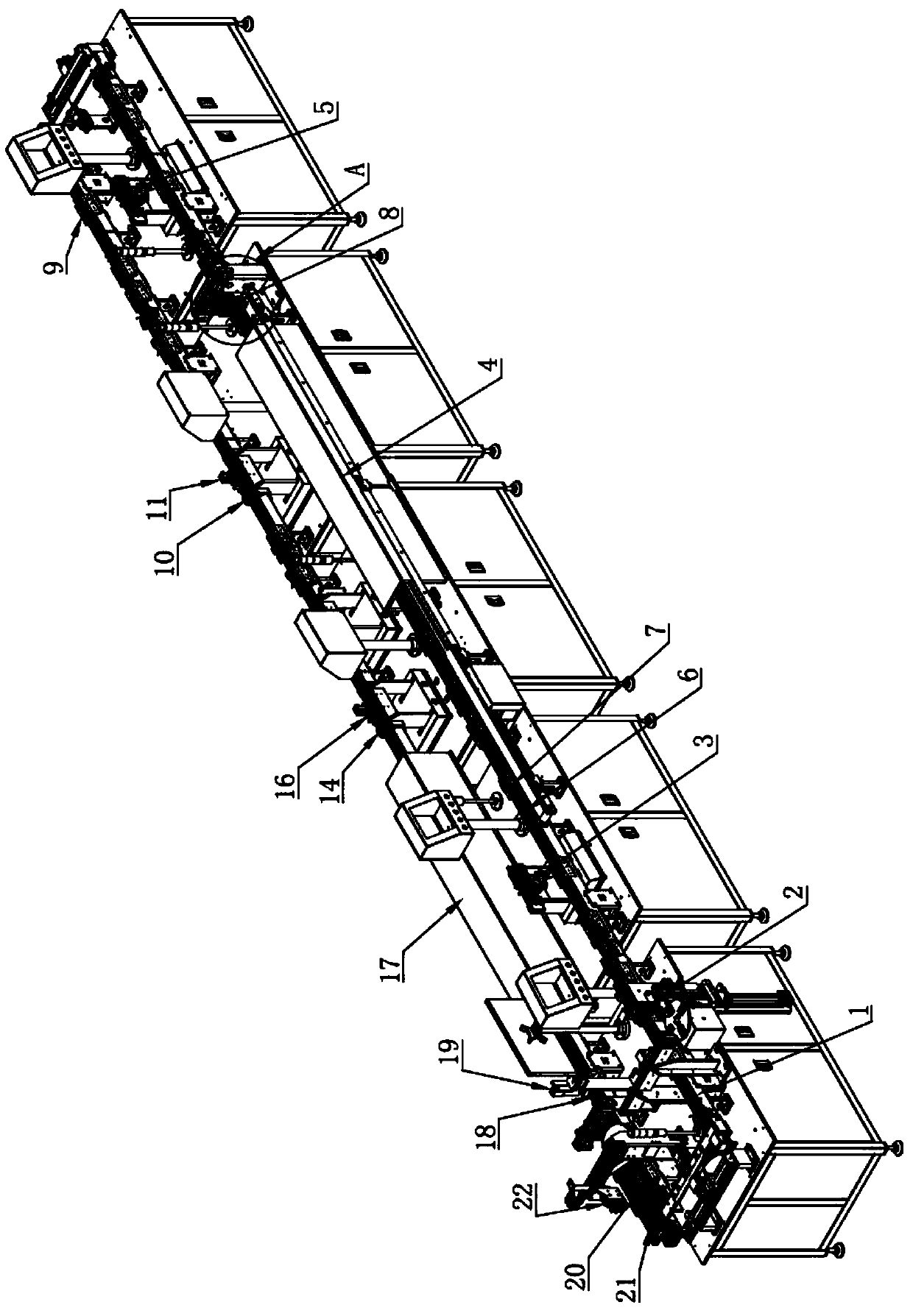

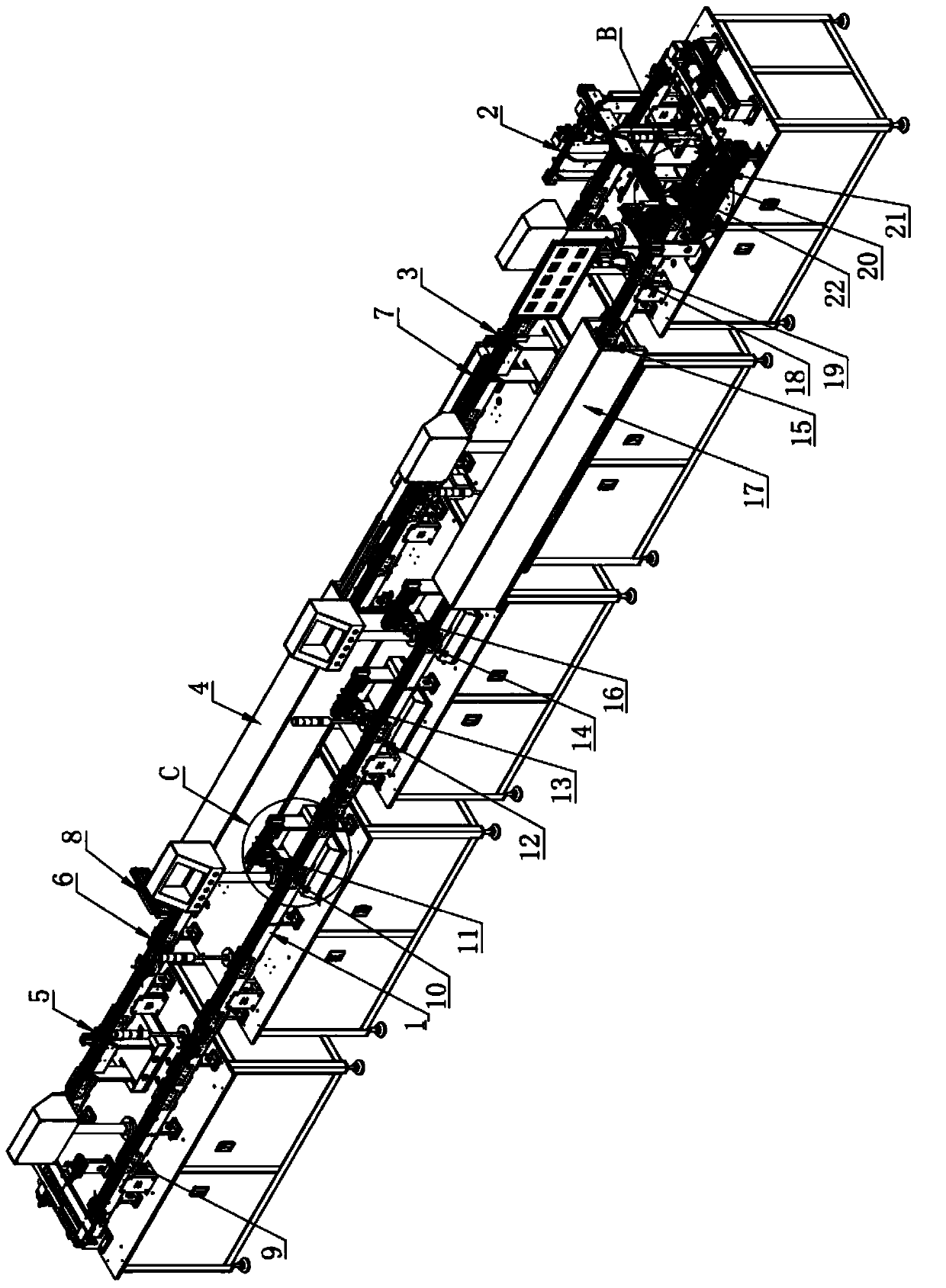

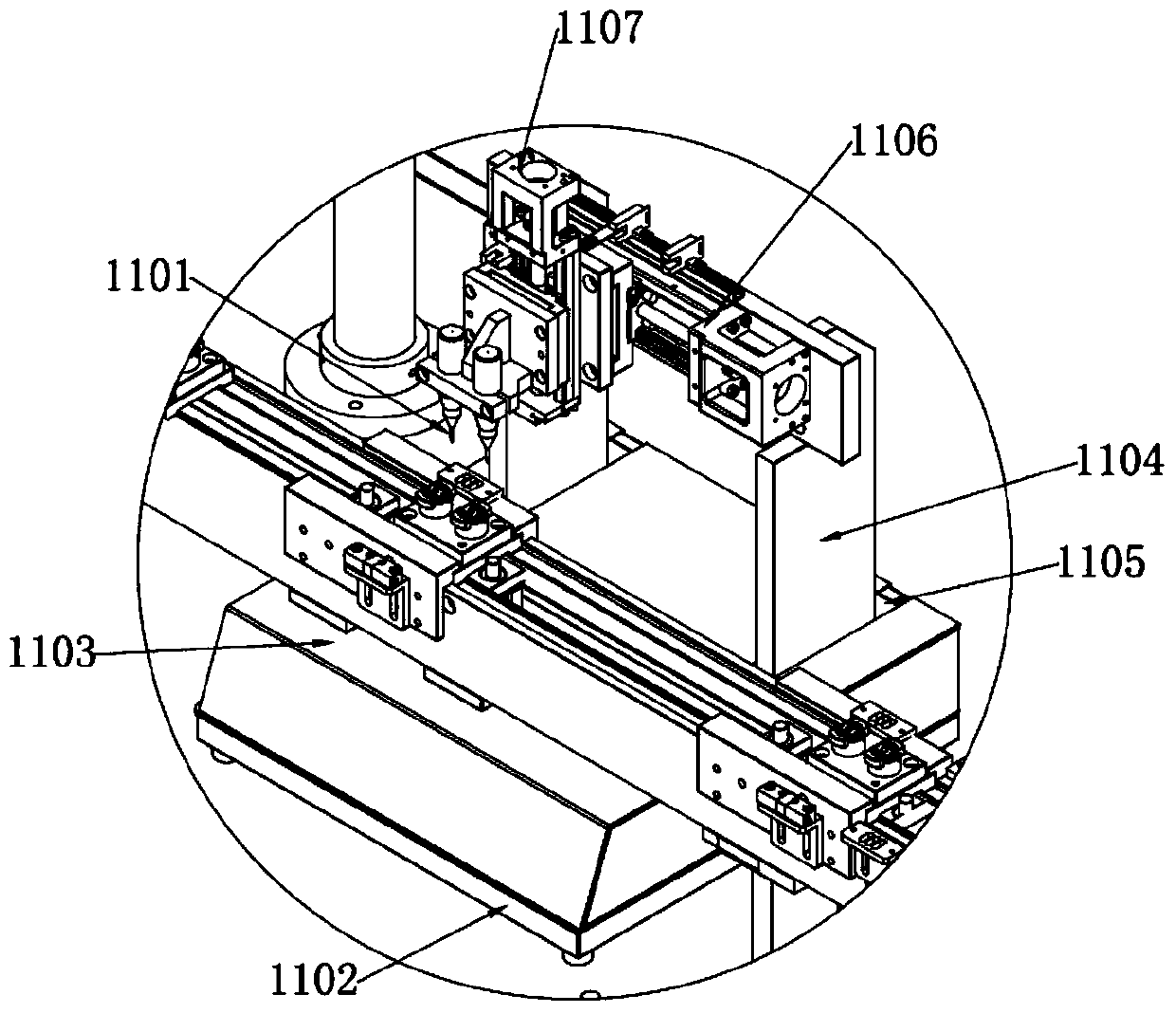

[0029] Such as figure 1 and figure 2 As shown, the present embodiment provides a loudspeaker sound film component assembly equipment, including an automatic transmission line 1, and automatic process equipment arranged on the side of the automatic transmission line 1. machine 2, sound diaphragm center automatic dispensing machine 3, first glue curing machine 4 and first lead wire dispensing machine 5, the assembly line 1 of the automatic transmission is provided with more than four stations, and the assembly line is provided with There is a translation belt and a motor that drives the translation belt transmission. The translation belt is loaded with jigs 6, and the jigs 6 pass through the above-mentioned stations in turn. Each station corresponds to the automatic process equipment. The center of the sound diaphragm Between the automatic dispensing machine 3 and the first glue curing machine 4, there is a manual voice coil cover station 7 for manually buckling the voice coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com