Micro loudspeaker production method and device thereof

A technology of a micro-speaker and a manufacturing method, which is applied to sensors, electrical components, etc., can solve the problems of labor and time-consuming, reduced production efficiency, and increased cost, and achieves the effect of reducing manufacturing cost, improving production efficiency, and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

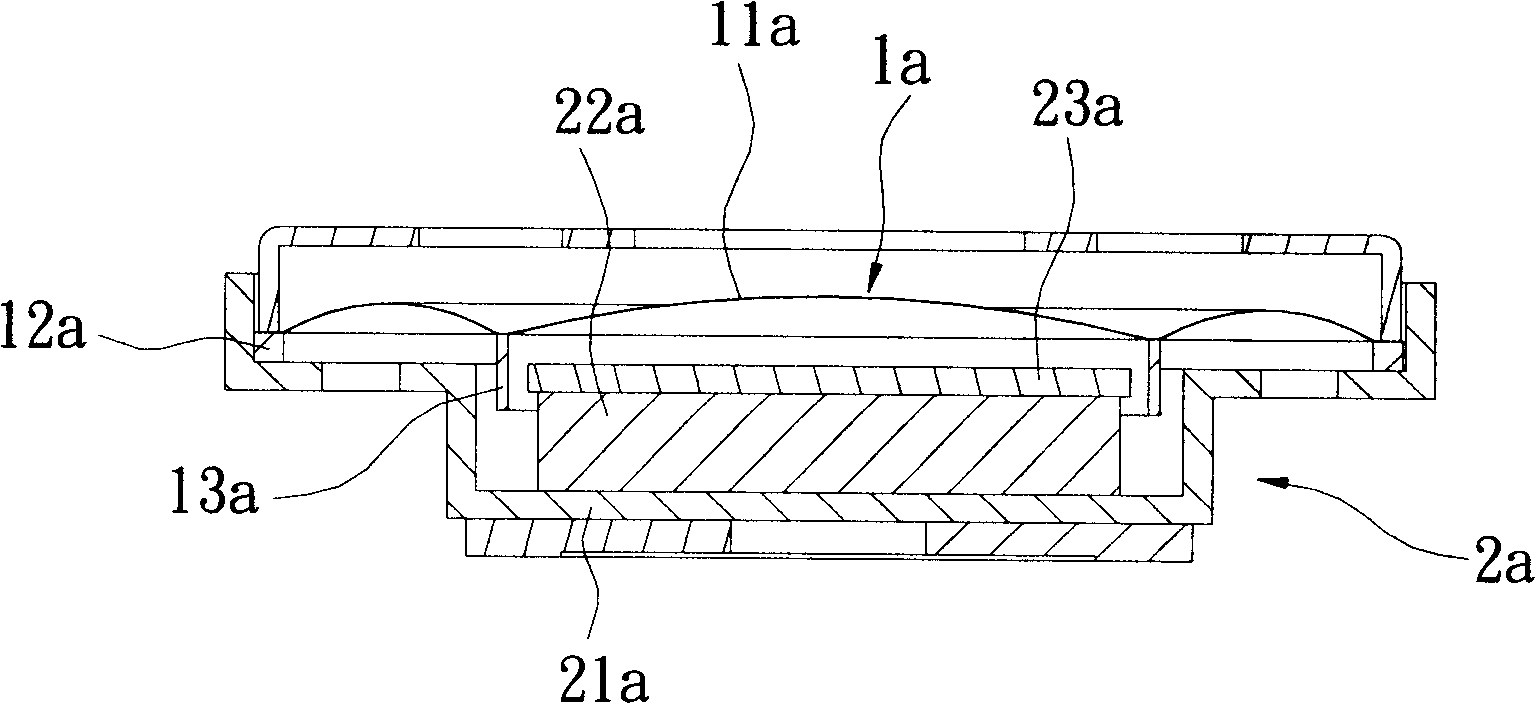

[0052] see Figure 4 , the invention provides a kind of miniature loudspeaker manufacturing method, it comprises steps as follows:

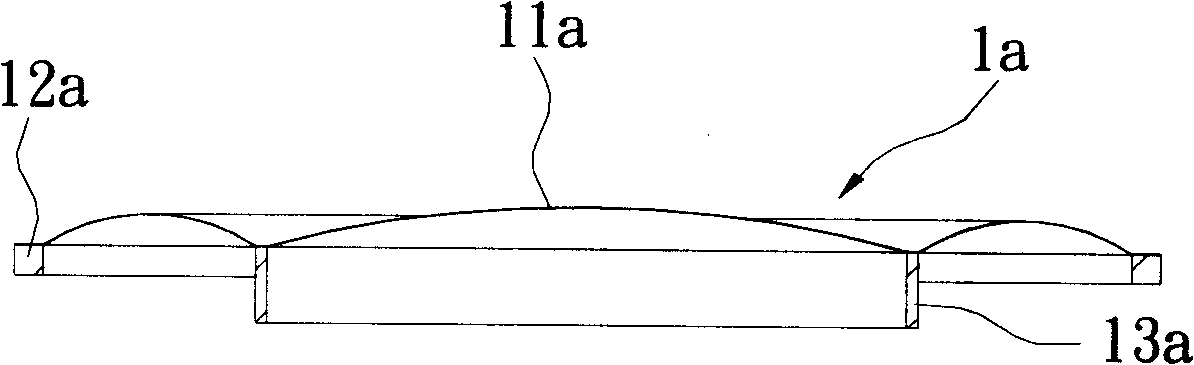

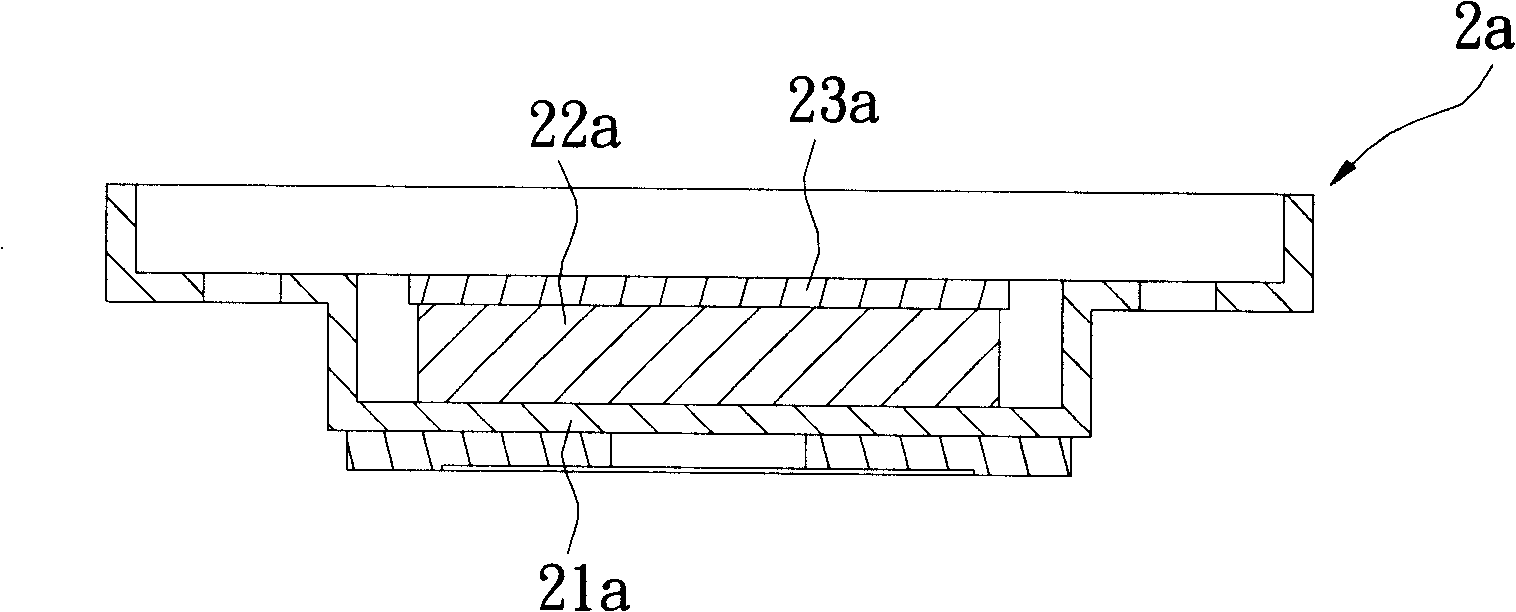

[0053] (a) At first, prepare a jig 1 and a jig top cover 2 (such as Figure 5 As shown), a circular flange 11 protrudes from the top surface of the jig 1, and a circular accommodating space 12 is opened inside the flange 11, and a bearing seat 13 protrudes from the center of the accommodating space 12. The top surface of the bearing seat 13 forms an arc surface; the bottom surface of the jig upper cover 2 forms a groove 21 corresponding to the flange 11, and a circular first perforation 22 and a conical first hole 22 are arranged above the groove 21. the second perforation 23;

[0054] (b) Then place an apron 3 made of plastic material in the accommodating space 12 of the jig 1 (as shown in FIG. 6 ), the apron 3 is placed in the accommodating space 12 in an upside-down state, The rubber ring 3 is a ring body, and a ring-shaped joint portion 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com