Micro-LED (Micro-light emitting diode) array backlight source-based ink-jet printing quantum dot display device

An inkjet printing and display device technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of complex yield of RGB three-color process, and achieve the effects of improving display performance, flexible design, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

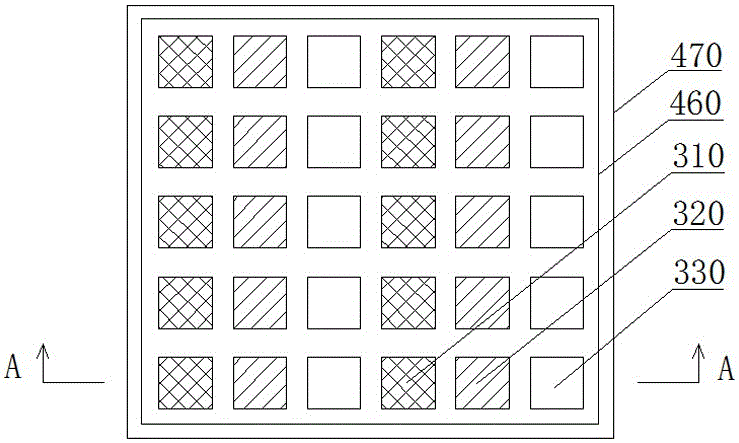

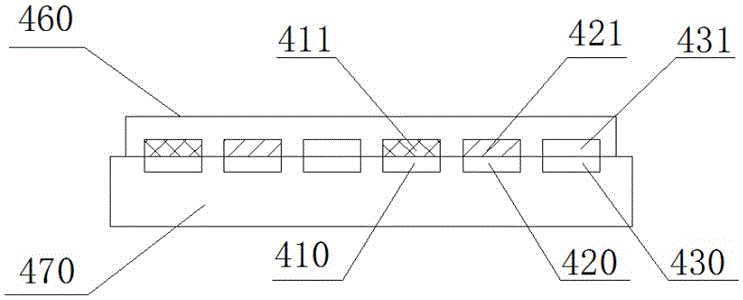

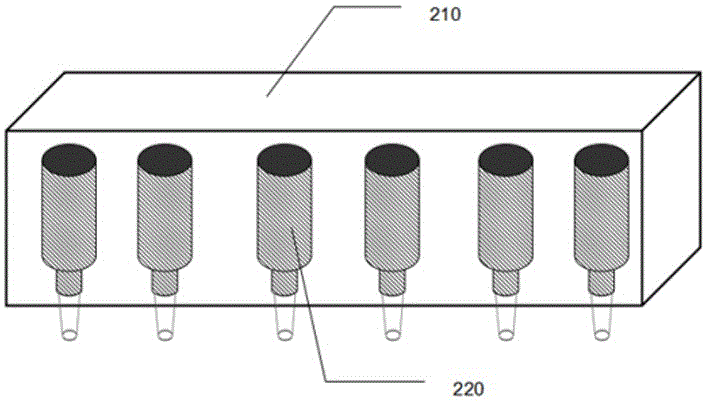

[0021] Please refer to figure 1 and figure 2 , the present invention provides an inkjet printing quantum dot display device based on a Micro-LED array backlight, which is characterized in that it includes a Micro-LED substrate 470, and the Micro-LED substrate 470 is provided with a number of RGB arrays arranged in an array. The pixel unit is an array of 5 rows and 2 columns in this embodiment, and each RGB pixel unit includes a red quantum dot unit 310, a green quantum dot unit 320 and a transparent unit 330; the red quantum dot unit 310 includes Micro- The LED chip 410 and the red quantum dot material 411 coated on the Micro-LED chip 410, the red quantum dot material 411 is excited by the blue light emitted by the Micro-LED chip 410 to emit red light; the green quantum dot unit 320 includes The Micro-LED chip 420 and the green quantum dot material 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com