Counterpoint mark and method for using same to manufacture workpieces in exposure process

A technology of alignment marks and alignment marks, which is applied to microlithography exposure equipment, photoplate-making process on patterned surfaces, and originals for photomechanical processing, etc. It can solve problems such as the inability of alignment of exposure machines to achieve improved Yield rate and production efficiency, reduction of pre-alignment steps, and production cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, the manufactured workpiece is a semiconductor element, and the semiconductor element is specifically a TFT device, and the TFT device includes N-layer patterns, where N>2. The first layer pattern of the TFT is made by exposing the first mask by the exposure machine, and correspondingly, the other layers of the TFT are respectively made by exposing the i-th mask by the exposure machine, and the first mask The first alignment mark 7 is set on the i-th mask, and the i-th alignment mark 8 is set on the i-th mask. In this embodiment, the exposure machine is a scanning exposure machine.

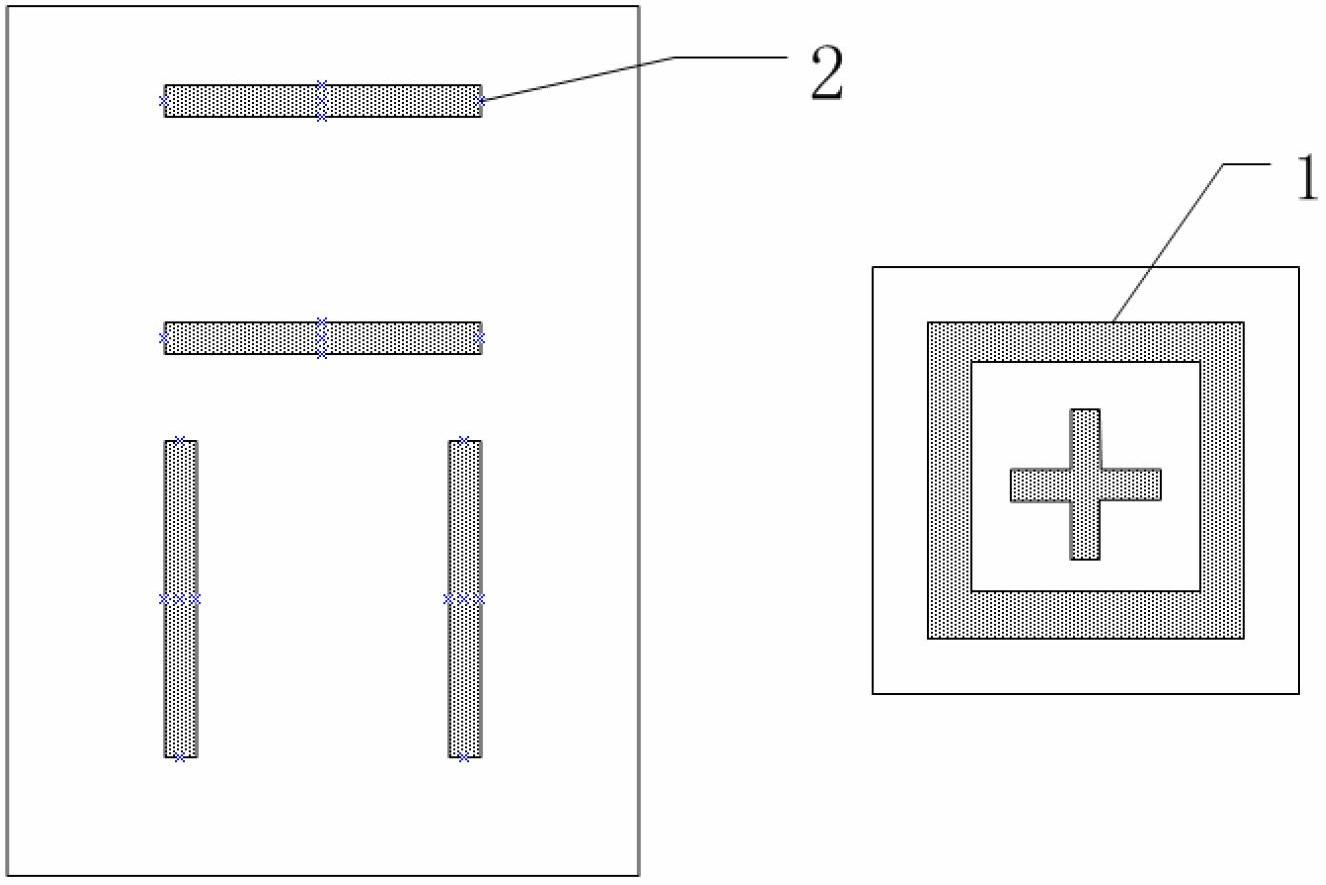

[0044] Such as Figure 5 As shown, the first alignment mark 7 is set on the first mask. In this embodiment, the first alignment mark 7 includes a first sub-mark 11, a second sub-mark 12, a third sub-mark 13 and a fourth sub-mark The marks 14 , that is, the first sub-mark 11 , the second sub-mark 12 , the third sub-mark 13 and the fourth sub-mark 14 are all set on the fi...

Embodiment 2

[0062] The difference between this embodiment and Embodiment 1 lies in that the shape of the first alignment mark 7 in the first mask is different from that in Embodiment 1.

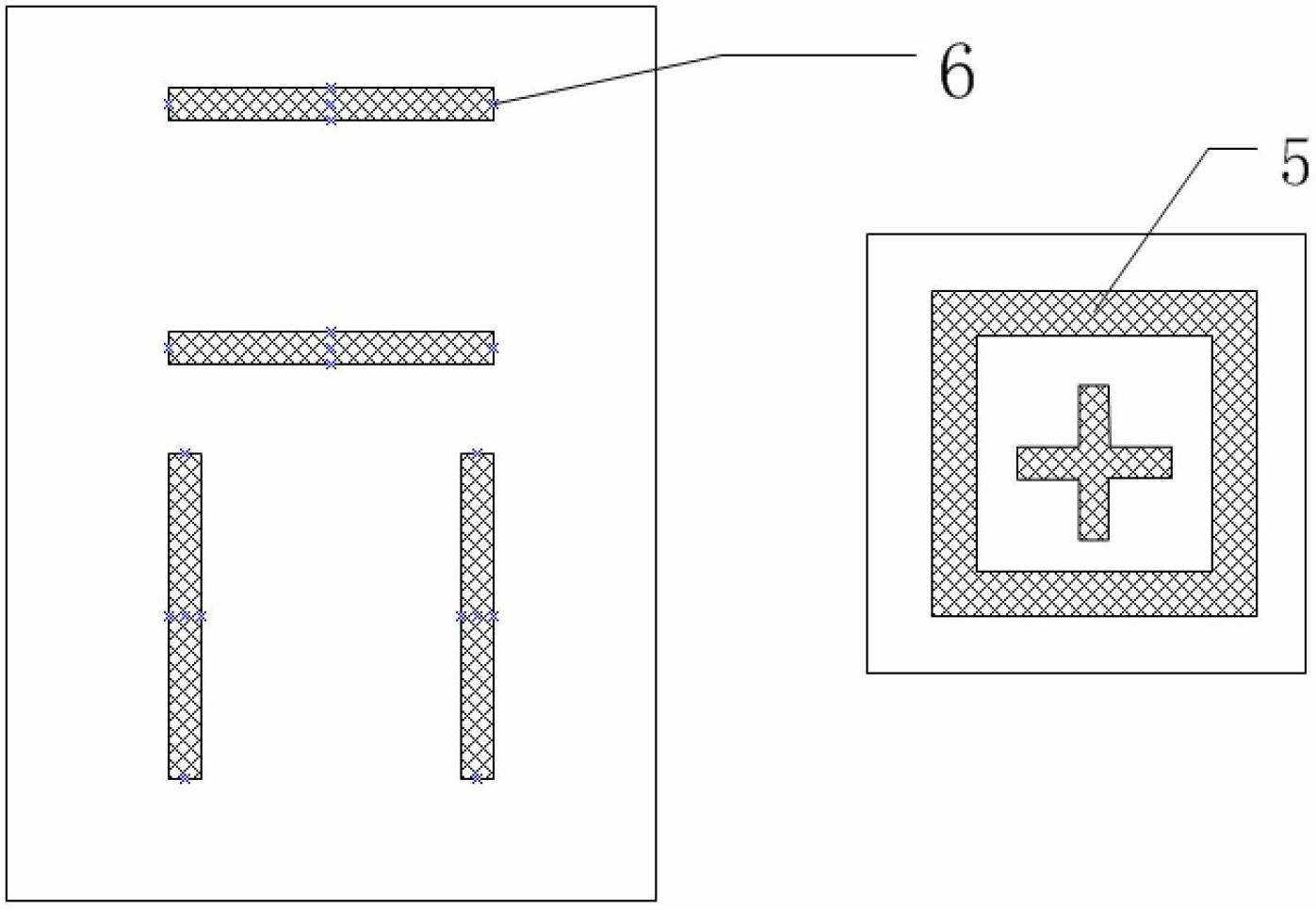

[0063] In this example, if Figure 9 As shown, the first sub-mark 11, the second sub-mark 12, the third sub-mark 13 and the shape of the fourth sub-mark 14 are all the same square, and its essence is to divide a square into four equal parts (each equal part The shape of the sub-mark is a square), and the shape of the spacing between the first sub-mark 11, the second sub-mark 12, the third sub-mark 13, and the fourth sub-mark 14 is a hollow cross, that is, a cross is used to divide the square.

[0064] In this embodiment, the shape of the i-th alignment mark 8 in the i-th mask is the same as that in the first embodiment.

[0065] The other structures of the alignment mark in this embodiment and the method of using the alignment mark to make a TFT in the exposure process are the same as those in Embodimen...

Embodiment 3

[0067] The difference between this embodiment and Embodiment 1 lies in that the shape of the first alignment mark 7 in the first mask is different from that of Embodiment 1.

[0068] In this example, if Figure 10 As shown, the first sub-mark 11, the shapes of the second sub-mark 12, the third sub-mark 13 and the fourth sub-mark 14 are all the same sector, which is essentially a circle divided into four equal parts (each equal part The shape of the sub-mark is a fan), and the shape of the spacing between the first sub-mark 11, the second sub-mark 12, the third sub-mark 13, and the fourth sub-mark 14 is a hollow cross, that is, the cross divides the circle .

[0069] In this embodiment, the shape of the i-th alignment mark 8 in the i-th mask is the same as that in the first embodiment.

[0070] The other structures of the alignment mark in this embodiment and the method of using the alignment mark to make a TFT in the exposure process are the same as those in Embodiment 1, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com