Three-dimensional memory device and preparation method thereof

A three-dimensional storage and device technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problem that the bottom of the channel hole cannot be opened and electrically connected to the substrate, and the side wall of the channel hole and its filling can be easily damaged. , channel holes are not easy to accurately align, etc., to achieve the effect of shortening the process cycle, high yield rate, and good structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Although exemplary embodiments of the invention are shown in the drawings, it should be understood that the invention may be practiced in other ways than those described herein, and therefore, the invention is not limited by the following embodiments.

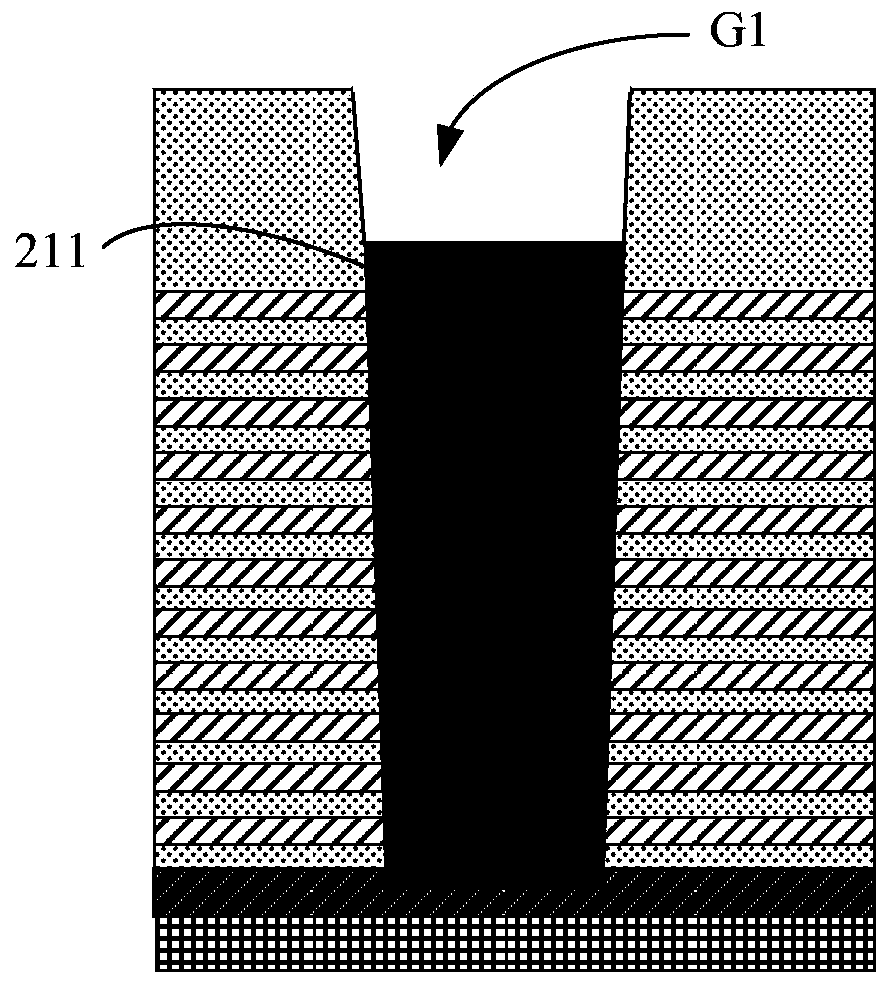

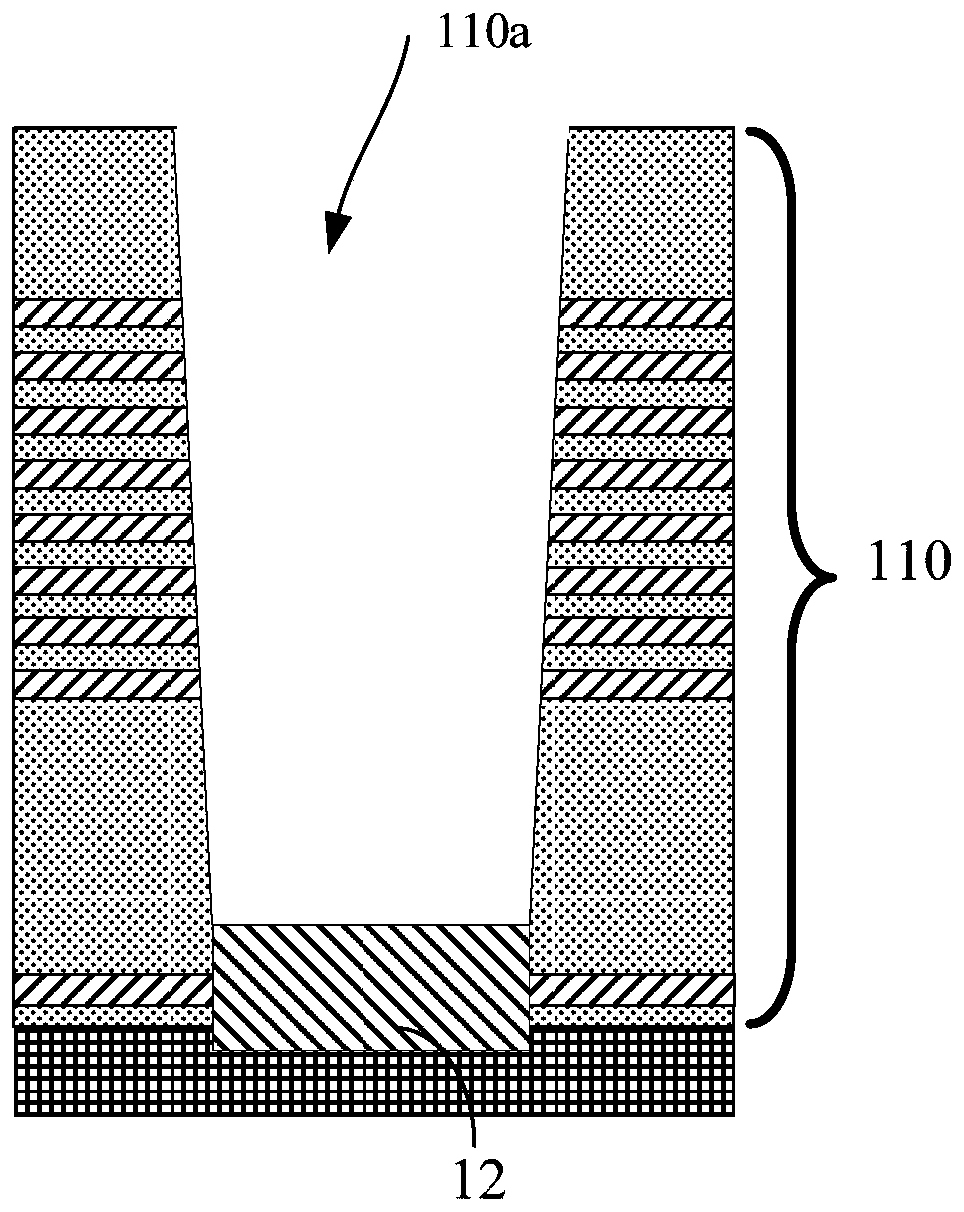

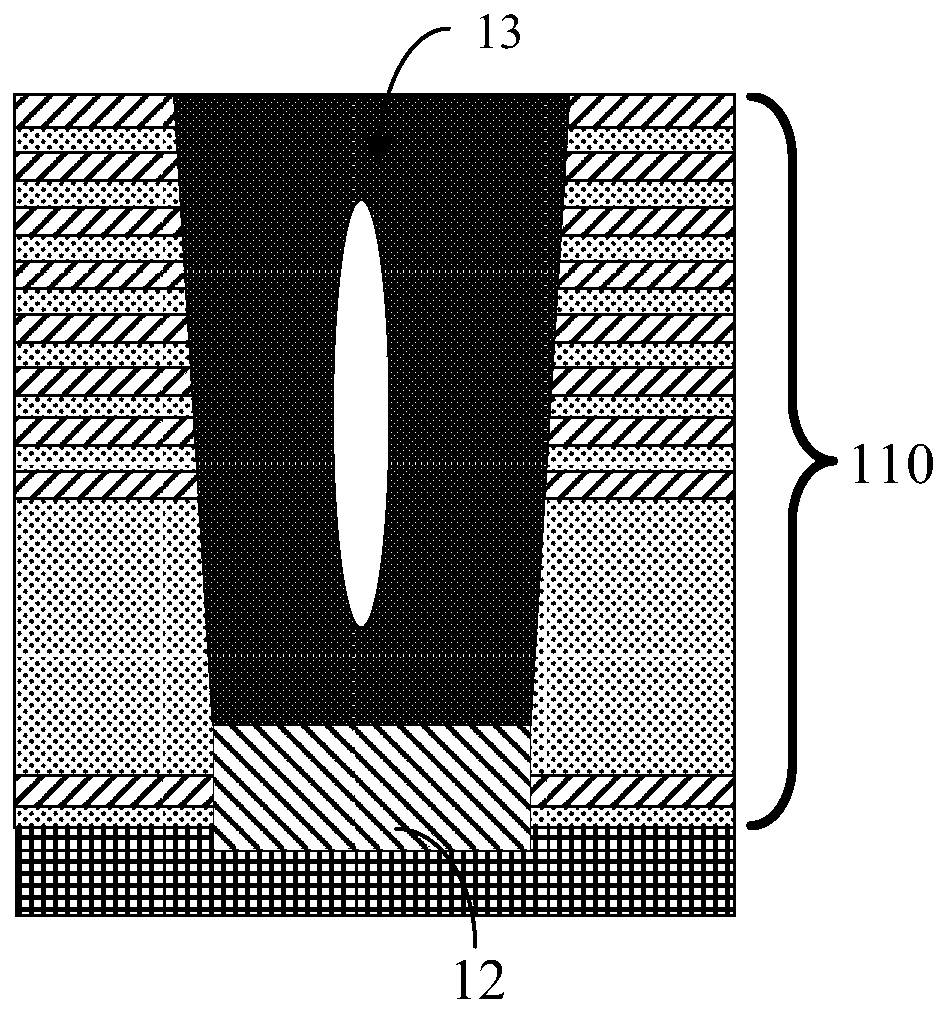

[0038] Before describing the specific implementation of the present invention, first briefly introduce the single-channel preparation process commonly used in the industry in three-dimensional memory devices: grow an epitaxial structure 12 at the bottom of the lower layer channel hole 110a of the lower layer stack 110 (see Figure 1a ), and fill the sacrificial material 13 on the epitaxial structure 12 (see Figure 1b ); then form an upper layer stack 120 and an upper layer channel hole 120a corresponding to the lower layer channel hole 110a on the lower layer stack 110 (see Figure 1c ), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com